Products

|

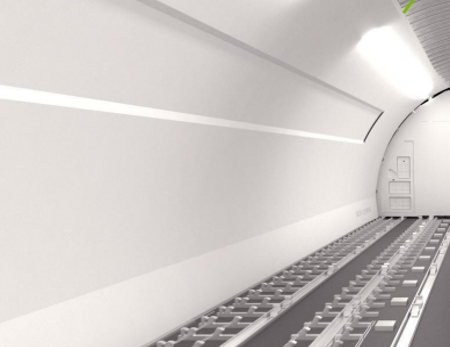

In recent years, the expansion of the e-commerce market is expected to drive increased demand for both passenger and cargo aircraft/Freighter. These changes in the market environment present significant business opportunities for our Group, which operates in the aircraft interior components sector. Production Plant Laboratory |

Applications

The production of the cargo liner was achieved by leveraging SNC's thermoset resin composite laminate technology and Vaupell's injection molding, painting and assembly expertise for aircraft interior components. SNC handles the molding and processing of resin products used in interior components, while Vaupell China (Dongguan) Co., Ltd. carries out thermoplastic injection molding and painting of the molded parts. These are consolidated at Vaupell Europe GmbH in Germany, where they undergo assembly before delivery to Airbus. This product obtained certification from Airbus in April 2024, with mass production shipments commencing in September 2025.

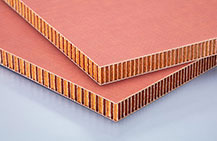

By laminating and curing prepregs impregnated with our proprietary bio-based resin 'sbPFATM', we can offer high-performance, sustainable cargo liners. Leveraging our strengths as a materials manufacturer, we will continue to deliver unique value propositions.

Topics More

- 2026/01/30 Products Development of Biomass PFA Resin-Based Prepreg with Superior Flame Retardancy for Aircraft Interior Materials

- 2026/01/15 Products Adoption of Heat-Dissipating Insulating Sheet in Resin-Insulated Substrate Integrated Power Module

- 2026/01/13 Products Sustainability Topics: Launch of the Website Towards the Sustainability of Phenolic Resins

- 2026/01/13 Products Initiatives for Mechanical Recycling of Phenolic Resin Products

- 2025/11/13 Products Launch of Mass Production of the Main Deck Cargo Liner for Airbus’ New A350F Freighter Aircraft

Inquiry

Inquiry