November 13, 2025

Sumitomo Bakelite Co., Ltd. (Headquarters: Shinagawa-ku, Tokyo; President and Representative Director: Shinichi Kajiya) announces that its group company, Vaupell Group (hereinafter referred to as Vaupell), successfully delivered the first parts for the main deck cargo liner of Airbus’ new cargo aircraft, the A350F, in September 2025. As a result, mass production shipments have commenced.

Overview and Background

With the growth of the global economy, the demand for passenger aircraft is expected to surpass pre-COVID-19 pandemic levels. Furthermore, the recent expansion of the e-commerce market is anticipated to drive increased demand not only for passenger aircraft, but also cargo aircraft. These changes in market dynamics present significant business opportunities for our group, which operates in the aircraft interior business.

To meet the growing demand for cargo aircraft, our group has established a new production line for aircraft interior components at SNC Industrial Laminates SDN. BHD. (hereinafter referred to as SNC) in Malaysia. We have developed a new integrated production system for manufacturing aircraft interior components by combining Vaupell’s expertise in supply chain management and final product assembly with our advanced resin technologies.

Start of Mass Production of A350F Cargo Liners with Integrated Production

The next-generation large cargo aircraft, the A350F, will be equipped with the ordered cargo liners. In addition, Vaupell was recognized as a Tier 1 supplier to Airbus in 2019.

|

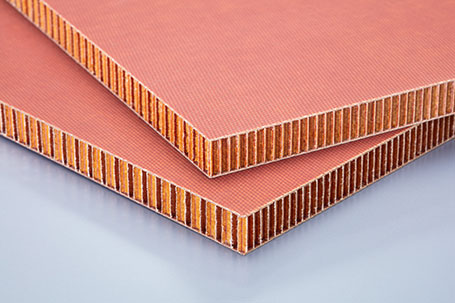

The production of the cargo liners has been realized by leveraging SNC’s thermosetting resin composite laminate technology and Vaupell’s expertise in injection molding, painting and assembly for aircraft interior components. At SNC, resin products used for aircraft interior components are molded and processed. Thermoplastic injection molding and painting of molded products are conducted at Vaupell China (Dongguan) Co., Ltd. The components are then consolidated at Vaupell Europe GmbH in Germany, where they undergo assembly before being delivered to Airbus. This product received process certification from Airbus in April 2024 and mass production shipments began in September 2025. |

|

Future Plans

By leveraging the synergies of our resin technologies with assembling and manufacturing techniques that meet various aviation industry certification standards, we aim to further expand our business with Airbus.

• Overview of Vaupell Group

|

Headquarters: |

Vaupell is a global supplier that leverages material science and molding technologies to provide engineering solutions for commercial aerospace applications, ranging from resins to aircraft interior subassemblies.

|

|

• Overview of SNC Industrial Laminates SDN. BHD.

|

Headquarters: |

|

SNC began its operations with the manufacturing and sales of circuit materials, including copper-clad laminates. Today, the company has expanded its business portfolio to include the manufacturing and sales of phenolic resins and aircraft interior components, establishing three core pillars of its business. |

Related Information

[Contact information]

Marketing Dept., Material Solutions Sales Div.

Sumitomo Bakelite Co., Ltd.