Products

sbPFA™ is the brand for a range of products developed by our company utilizing non-edible biomass-derived PFA (PolyFurfuryl Alcohol) technology. |

Materials used in aircraft interiors are subject to stringent fire resistance

requirements under national regulations, with the aim of preventing the spread

of fire in order to ensure the safety of passengers and crew in the event of a

fire occurring inside or outside the aircraft.For this reason, Fesneau resin,

which has high fire resistance properties, has long been used as an aircraft

interior material. Production Plant Laboratory |

Features

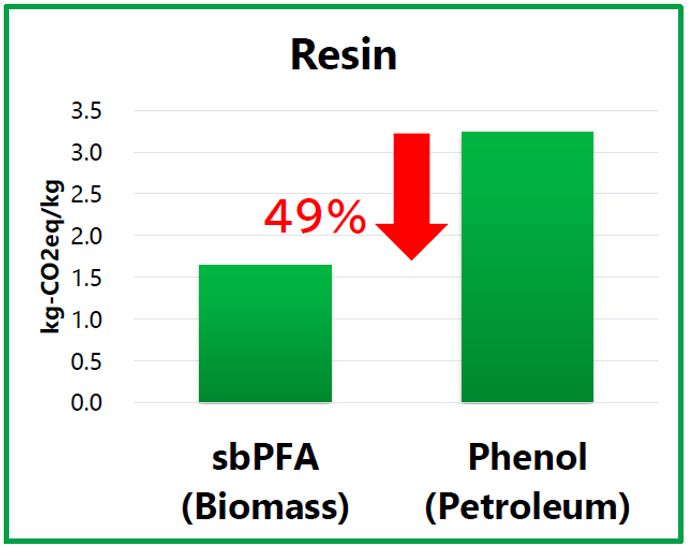

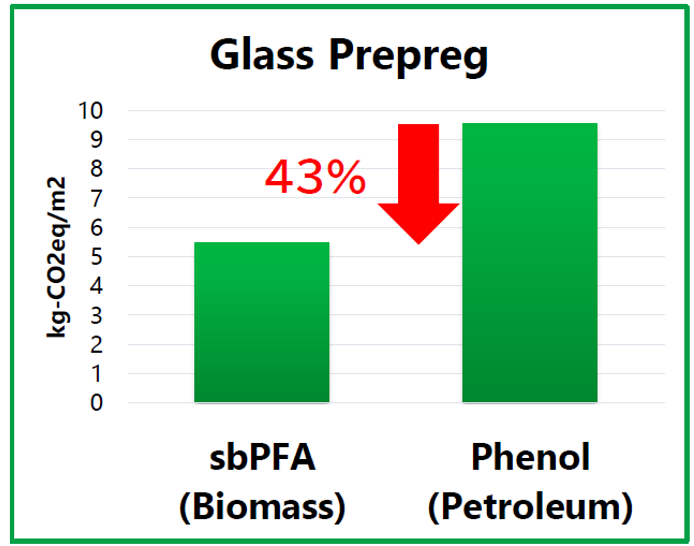

It reduces the carbon footprint by 49%, which was difficult to achieve with conventional phenolic resin prepregs, and contributes significantly to the aviation industry's goal of achieving carbon neutrality by 2050. This promotes the improvement of corporate ESG ratings and brand image. The use of non-edible biomass raw materials enables sustainable procurement and enhances environmental consideration throughout the supply chain.

It ensures the excellent flame retardancy, low smoke emission, and low toxicity (FST) performance essential for aircraft interior materials, while being handled in exactly the same way as conventional phenolic resin prepregs. This enables a smooth transition to environmentally conscious materials without requiring new capital investment or significant changes to manufacturing processes. It allows companies to continue providing highly safe products while maintaining manufacturing efficiency.

- As resins, sbPFA™ reduces CFP by 49% compared with conventional phenol for prepreg.

- As glass prepreg, SBPFA™ reduces CFP by 43% compared with phenol.

- Database: IDEA v2.3

- Affected area: 100 time horizon (IPCC, 2013)

- Characterization model, Subjects: Climate change

- System boundary: Absorption by photosynthesis ~ Raw material mining ~ shipment

- Production plant: Shizuoka Plant

- Data collection period: April 2023 to March 2024

Applications

Proposal for sustainable materials to EU aerospace companies that are leading the way in environmental responsiveness.

Specifications

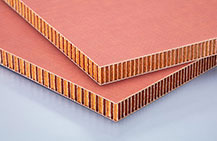

Glass fabrics impregnated with PFA

sbPFA® prepreg is a glass fabric impregnated with PFA (PolyFurfuryl Alcohol) resin systemderived from biomass-based furfuryl alcohol.

| Style | - | E-glass #7781 |

| Weave | - | 8H Satin |

| Weight | g/m | 295±6 |

| Thickness | mm | 0.225±0.020 |

| Resin type | - | PFA |

| Resin content | % | 41 |

| Flow | %, 121°C for 10min, 0.3MPa | 18 |

| Volatiles | %, 121°C for 10min | <3 |

Representative values, not certified

- Temperature - 130°C

- Heating rate - 3-5°C/min

- Curing time - 60 min

- Pressure - 0.4-1.0MPa

Topics More

- 2026/01/30 Products Development of Biomass PFA Resin-Based Prepreg with Superior Flame Retardancy for Aircraft Interior Materials

- 2026/01/15 Products Adoption of Heat-Dissipating Insulating Sheet in Resin-Insulated Substrate Integrated Power Module

- 2026/01/13 Products Sustainability Topics: Launch of the Website Towards the Sustainability of Phenolic Resins

- 2026/01/13 Products Initiatives for Mechanical Recycling of Phenolic Resin Products

- 2025/11/13 Products Launch of Mass Production of the Main Deck Cargo Liner for Airbus’ New A350F Freighter Aircraft

Inquiry

Inquiry