January 13, 2026

Sumitomo Bakelite Co., Ltd. (Headquarters: Shinagawa-ku, Tokyo; President and Representative Director: Shinichi Kajiya) is expanding the commercial operation of mechanical recycling for phenolic resins, which were previously considered difficult to recycle. This involves finely pulverizing offcuts generated during the molding process and reusing them. This initiative contributes to reducing greenhouse gas (GHG) emissions, promoting resource circulation, and minimizing waste. Moving forward, we will focus on developing technologies for the application of higher-performance materials, particularly in the automotive sector, while strengthening collaboration with customers to realize a circular society.

Background of Development

In recent years, environmental issues such as global warming and the increase in waste have become increasingly severe. To address these challenges, reducing GHG emissions for achieving carbon neutrality and promoting resource circulation for a circular economy are vital.

In the plastics industry, the development of recycling technologies has become an important social issue. Among recycling methods, mechanical recycling, which physically returns materials to their raw state, is considered to be a priority to reduce environmental impact. While recycling of thermoplastics, which account for approximately 90% of domestic plastic production, has advanced through re-melting processes, phenolic resin, a thermosetting resin that does not re-melt once hardened, has been regarded as a difficult material to recycle.

Characteristics and Recyclability of Phenolic Resin

Phenolic resin is highly durable among plastics and has a long product lifespan. However, it has been considered challenging to recycle. Recent studies have shown that ends from molded products can be finely pulverized and reused as fillers (reinforcing materials), making recycling possible.

Additionally, recent research has confirmed that phenolic resin exhibits very little degradation during use and can maintain sufficient performance even after recycling. This challenges the conventional perception and demonstrates that phenolic resin is, in fact, suitable for mechanical recycling (see Table 1).

| Phenolic Resin | Thermoplastic Resin | |||

| Recyclability | Does not melt, lacks fluidity, hard to recycle Pulverization and compounding required |

△ | Melts, easy for melt blending On-site recycling possible |

〇 |

| Quality of Recycled Material | Resistant to degradation Recyclable multiple times |

〇 | Degrades easily Requires caution for repeated recycling |

△ |

| Application | Usable as filler for various applications | Recycled mainly into the same type of resin | ||

Recycling Initiatives

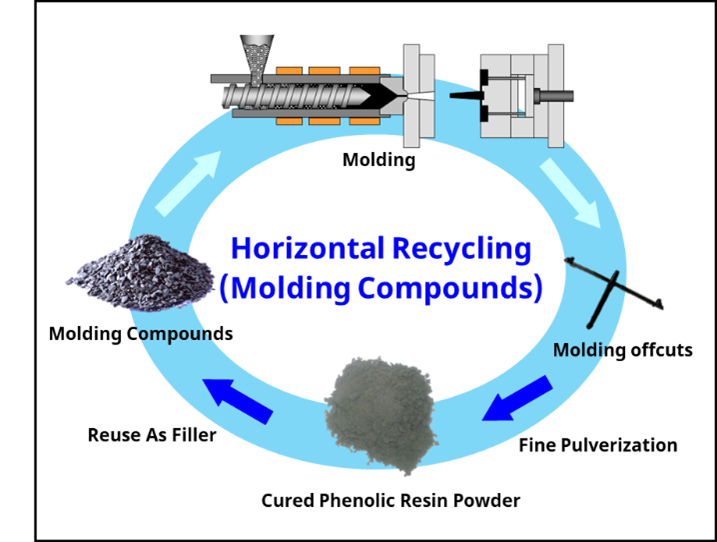

In the case of phenolic resin molding compounds, we have established a horizontal recycling system in which offcuts generated by parts manufacturers (e.g., Meiwa Industry Co., Ltd. [Headquarters: Tajimi City, Gifu Prefecture]) are finely pulverized by processing companies and reused as fillers in our molding compounds.

This initiative has been implemented as a technology that reduces waste while maintaining economic rationality.

Figure 1: Circular Flow of Horizontal Recycling

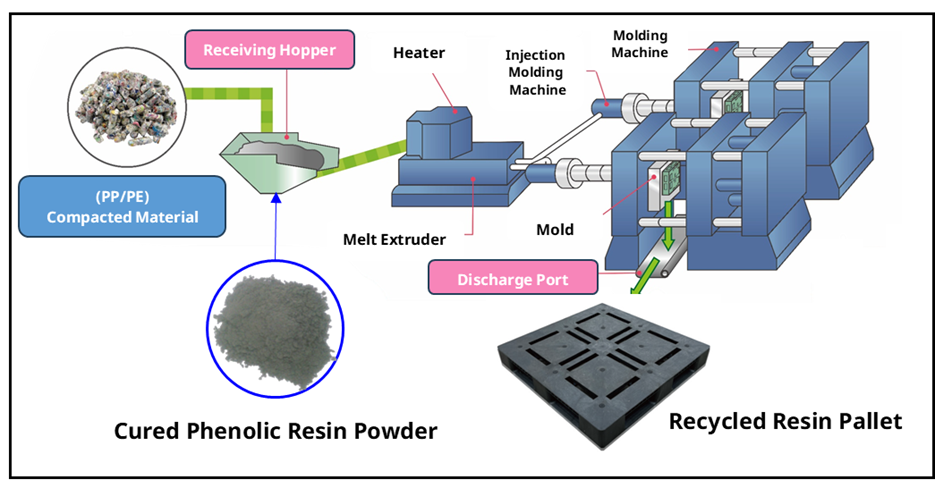

Furthermore, together with J&T Recycling Corporation [Headquarters: Kawasaki City, Kanagawa Prefecture; Yokohama City, Kanagawa Prefecture], we have undertaken efforts to recycle powdered cured phenolic resin by utilizing it as a filler for recycled resin pallets. These efforts have led to the development and commercialization of products that achieve a balance of performance, quality, and cost-effectiveness.

Figure 2: Reuse as Fillers for Thermoplastic Resins

Contribution to Carbon Neutrality

Phenolic resin is easy to pulverize, requiring less energy for grinding. As a result, the production of recycled materials generates a lower carbon footprint (CFP) compared to the production of virgin materials. (See Table 2.) In this way, promoting circular economy through resource circulation also contributes to the realization of carbon neutrality.

| Virgin Product | 20% Recycled Product | |

| Recycled Material Content (%) | 0 | 20 |

| CFP(kg-CO2eq/kg) | 3.0 | 2.5 (17% reduction vs virgin material) |

CFP Estimation Conditions

・Database: IDEA v2.3

・Impact Scope: 100-year Index (IPCC, 2013)

・Characterization Model and Target Items: Climate Change

・System Boundary: From Waste to Recycling Process/From Raw Material Extraction to Molding Material

・Production Plant for Molding Materials: Shizuoka Plant

・Data Collection Period: April 2024 – March 2025

・Unit Data: Energy consumption for the pulverization process of cured materials is based on data provided by the pulverization manufacturer.

・Molding Material Assumption: Glass fiber-reinforced PF-GF55 (45% organic components, 55% inorganic components).

・Assumption for Molding Scraps: 20% of the material usage is assumed to become molding scraps.

Future Plans

To further expand mechanical recycling of phenolic resin, we will focus on the automotive sector, where phenolic resin is most widely used. In particular, we aim to promote the recycling of waste products and used automotive parts by advancing technological development for applications in higher-performance materials. Additionally, through collaboration with customers, we aim to achieve a sustainable circular society.

Related Information

[Contact information]

Composite Materials & Molded Parts Sales Dept., Sumitomo Bakelite Co., Ltd.