January 30, 2026

Sumitomo Bakelite Co., Ltd. (Headquarters: Shinagawa-ku, Tokyo; President and Representative Director: Shinichi Kajiya) has developed a prepreg that utilizes biomass-derived PFA (PolyFurfuryl Alcohol, commonly known as furan resin) with superior flame-retardant properties to contribute to the aviation industry’s efforts to achieve CO2 net zero by 2050. This product serves as a sustainable solution that balances environmental impact reduction and safety in fields requiring advanced flame-retardant performance, such as aircraft interior materials. Through this innovation, we aim to contribute to the realization of a sustainable society.

Background of Development

The aviation industry is actively working toward the 2050 Carbon Neutral Target set by the International Air Transport Association (IATA) and the International Civil Aviation Organization (ICAO). As part of this initiative, major aircraft manufacturers are accelerating their decarbonization efforts. However, as FRP (Fiber Reinforced Plastics) becomes more prevalent for achieving aircraft weight reduction, addressing the challenge of reducing petroleum-based raw materials in the manufacturing process has become increasingly critical. Particularly with thermosetting resins, which are challenging to recycle, there is an urgent demand for the application of biomass-based materials to lower environmental impact. This calls for innovative solutions throughout the entire supply chain.

Our Initiatives and Product Features

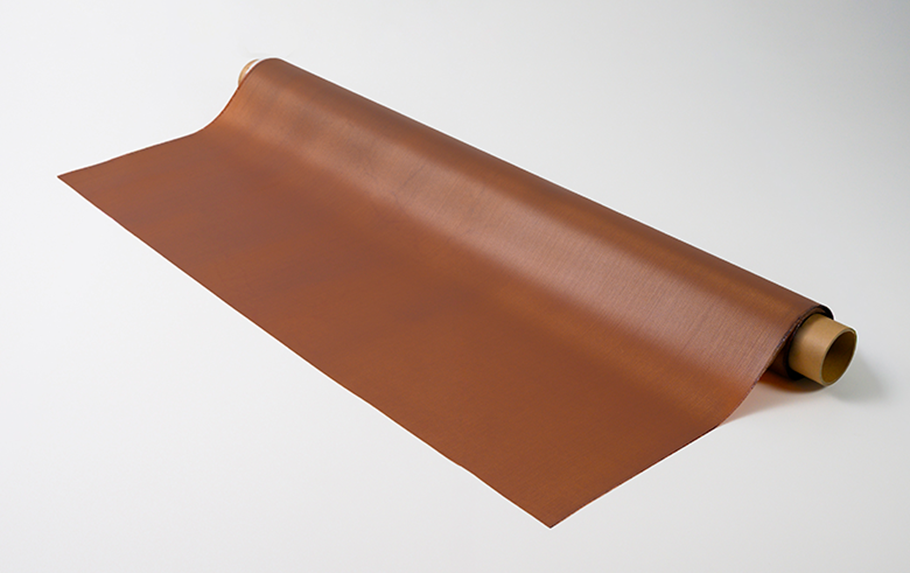

We have launched the brand sbPFA™ for non-edible biomass-derived PFA resin and its related products. As part of this initiative, we have developed a PFA prepreg that utilizes PFA resin as a binder. This prepreg is positioned as a solution to contribute to the aviation industry’s decarbonization efforts, driving both CO₂ reduction and sustainable product development. It offers mechanical strength comparable to conventional petroleum-based phenolic resins and meets the stringent flame retardancy, low smoke, and low toxicity (FST) standards required for aircraft interior materials. Additionally, it has demonstrated performance equivalent to petroleum-based phenolic resins in OSU heat release tests compliant with 14 CFR Part 25.

By streamlining the production process from PFA polymerization to prepreg manufacturing, we have reduced CFP (Carbon Footprint) by 43% compared to conventional products while maintaining equivalent mechanical strength. This development contributes to both environmental sustainability and enhanced safety and is ideal for applications such as aircraft interiors and automotive batteries requiring advanced flame retardancy.

sbPFA™ is the brand for a range of products developed by our company utilizing non-edible biomass-derived PFA (PolyFurfuryl Alcohol) technology.

Benefits of Introducing sbPFA™

1. Reduction of Environmental Impact and Enhancement of Corporate Value

The product achieves a 43% reduction in CFP, which was previously challenging with conventional phenolic resin prepregs. This significantly contributes to the aviation industry’s 2050 carbon-neutral target. Furthermore, it enhances ESG evaluations and brand image for companies. By utilizing non-edible biomass-based raw materials, we enable sustainable sourcing and strengthen environmental considerations across the entire supply chain.

2. High Safety and Compatibility with Existing Processes

The product ensures superior FST performance required for aircraft interior materials, while maintaining compatibility with existing handling methods for conventional phenolic resin prepregs. Therefore, it enables manufacturers to sustain production efficiency and continue delivering high-safety products without the need for substantial capital investments or extensive modifications to manufacturing processes.

Contribution to a Sustainable Society

The development of this product aligns with the Sustainable Development Goal 12: Responsible Consumption and Production. By utilizing non-edible biomass-based PFA resin, we have achieved a 43% reduction in CFP, fostering efficient resource utilization and minimizing environmental impact, thereby fulfilling our production responsibilities. Furthermore, the product’s superior FST performance contributes to enhanced safety, supporting a secure and resilient in a society. We remain committed to addressing global challenges through environmental innovation and collaborative partnerships.

Future Plans

The product is currently in the prototype phase, and we have started offering samples to several aircraft manufacturers. Moving forward, we will proceed with customer evaluations and aim to commence mass production by 2028. Beyond the aviation sector, we plan to expand into other fields requiring high flame retardancy, such as automotive batteries, and will strengthen our marketing efforts accordingly.

Related Information

[Contact information]

Marketing Department, Material Solutions Sales Division, Sumitomo Bakelite Co., Ltd.

TEL: +81-3-5462-4204