Product outline

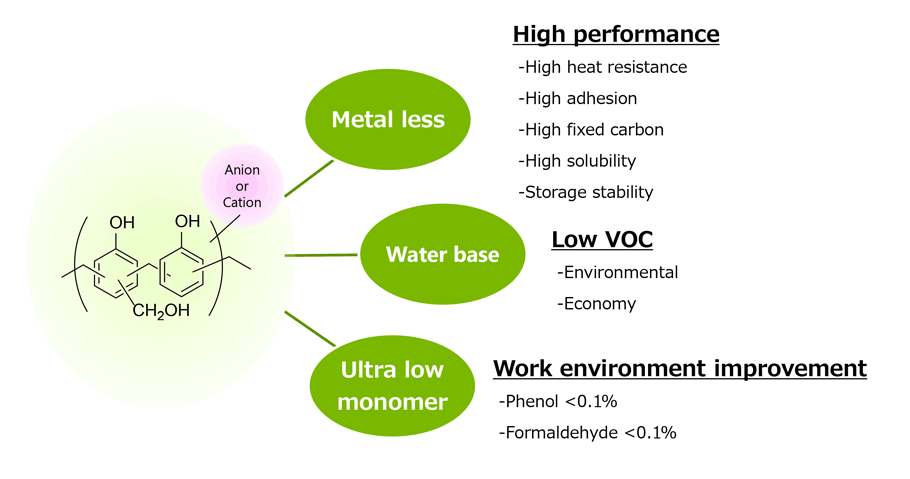

Water-soluble, low smell and low VOC phenolic resin

Water solution of phenolic resin with <0.1% of free phenol and free formaldehyde. This resin

can be dissolved in water, with quite low VOC and smell.

We expanded the lineup of grades with

various performance features.

We have a lineup of grades specialized for each function, such as high heat resistance, high adhesion, high carbonization rate, good solubility in various solvents, and long shelf life. All of them are water-based types and they have reduced unreacted monomers (phenol and formaldehyde), which can contribute to VOC reduction and improvement of your working environment.

Conventional water-soluble phenolic resins have issues to environmental restrictions depending on their unreacted monomers, but regarding ultra-low monomer water-soluble phenolic resins, they are expected to be used for wider application without such restrictions.

Technical data

You can check detailed data by clicking each grade name and feature.

| unit/condition | PR-56367 | PR-56449 | PR-56451 | PR-X25030S | PR-X25067 | |

| Type | - | Resole /Anion |

Resole /Anion |

Novolac /Anion |

Resole /Anion |

Resole /Cation |

| Feature | - | Standard | High heat resistance |

High fix carbon | High adhesion | High solubility |

| Free phenol | % | <0.1 | <0.1 | ← | ← | ← |

| Free formaldehyde | % | <0.1 | <0.1 | ← | ← | ← |

| Ash content | % | 4 | 0 | ← | ← | ← |

| Viscosity | mPa・s/25℃ | 70 | 770 | 3000 | 200 | 100 |

| Gelation time | Sec/150℃ | 50 | 68 | No gelation | 280* | 300 |

| Resin content | %/135℃ | 40 | 40 | 48 | 50 | 40 |

| pH | -/25℃ | 9.8 | 8.4 | 8.9 | 7.0 | 6.3 |

| Fixed carbon | %/800℃ | 19 | 15 | 18 | 12 | 16 |

* 165℃

Remark:The data given above are not guaranteed values.

PR-X***** is a development product,

and its grade name and specifications are subject to change.

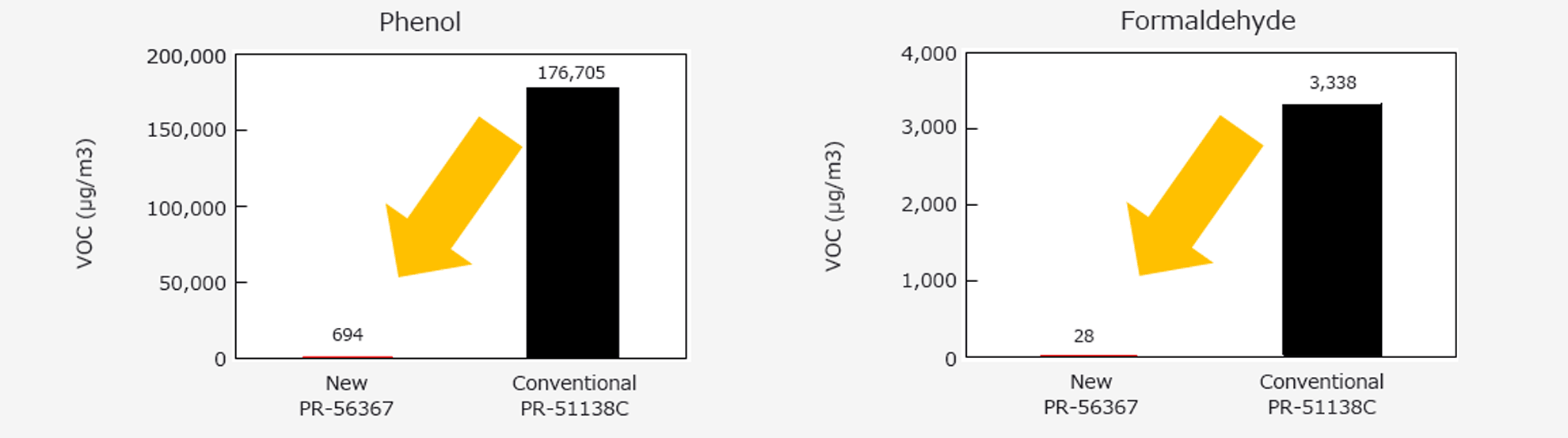

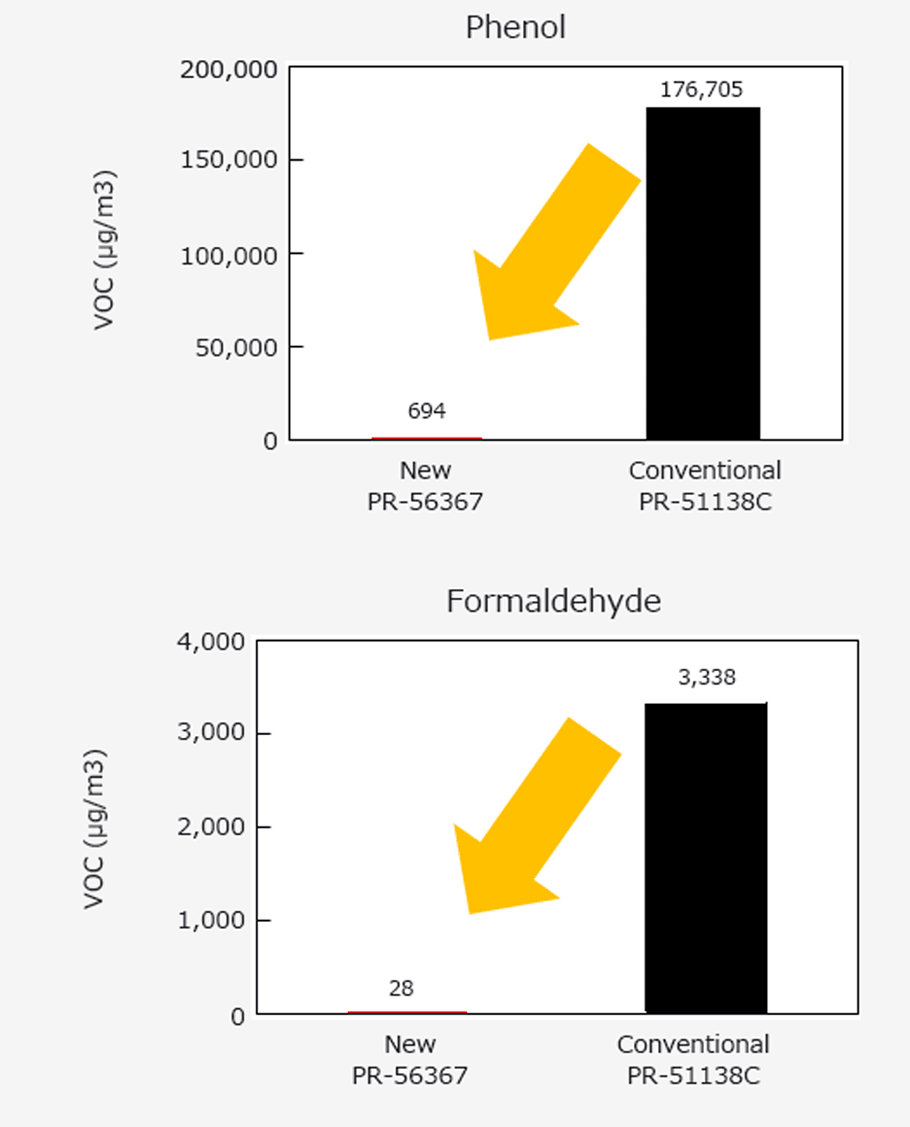

VOC

VOC of developed resin is much lower than general resin.

Application example

Binder or Additive for adhesive, Coating, Electronic industry material, Carbon material, EV

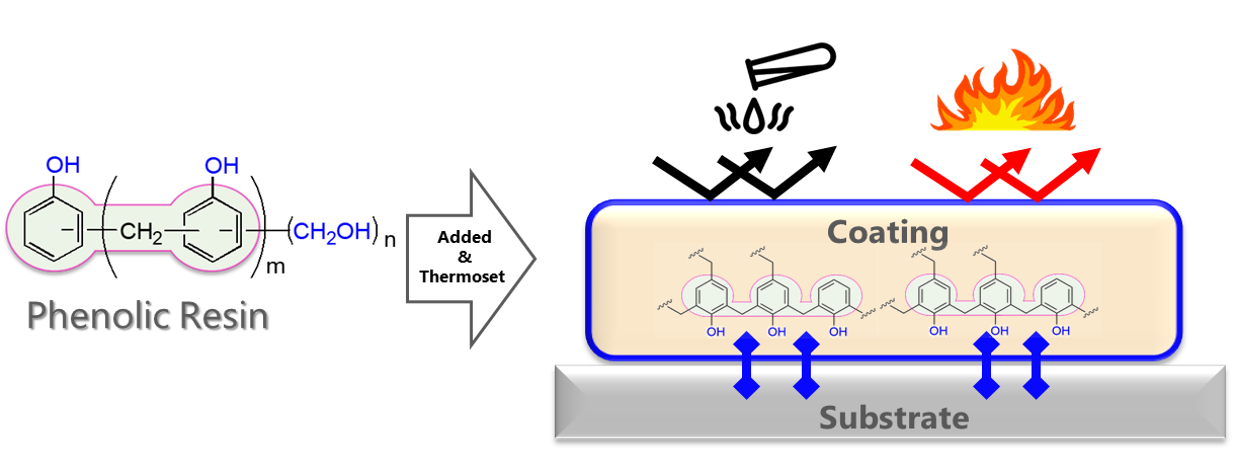

Case Study for Water-based Coatings

Phenolic resins contain a large number of OH groups which exhibit excellent adhesion properties. When added to coatings or surface treatment agents, they enhance the adhesion between the substrate and the coating after thermal curing, thereby contributing to improved corrosion resistance and heat resistance of the coating.

As an example, when monomer water-soluble phenolic resin AQNOA™ PR-56449 was added at 10% into various water-based paints and cured at 150°C for 20 minutes, the following properties were improved:

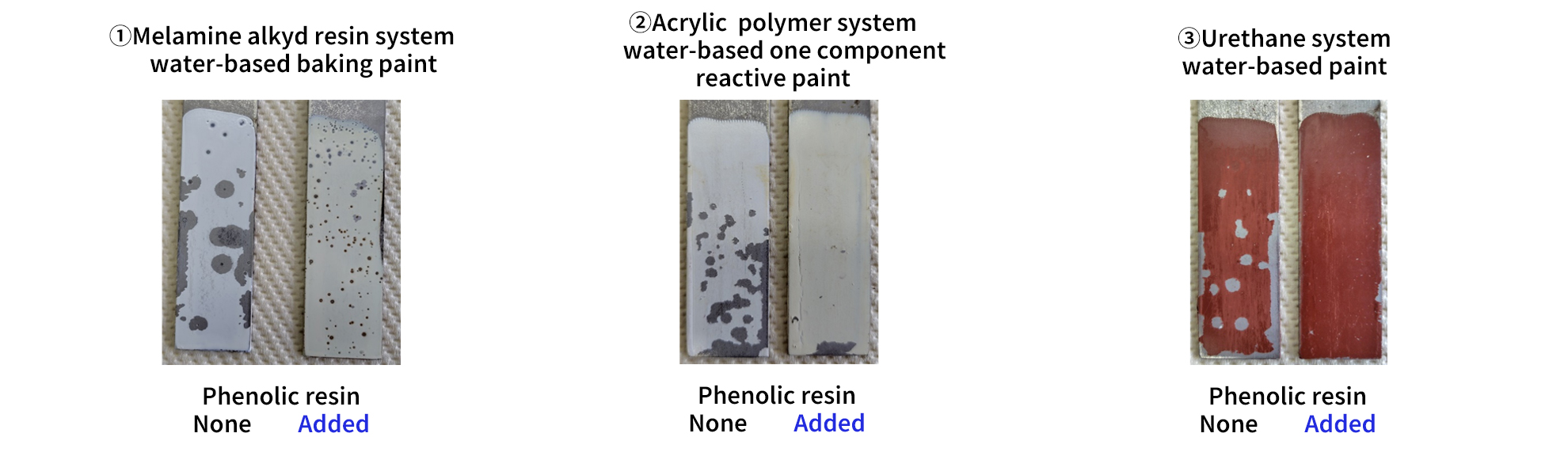

Corrosion resistance

After soaked in 20% salt water at 60°C for 12 hours, and rubbed 30 times with a cloth soaked in acetone.

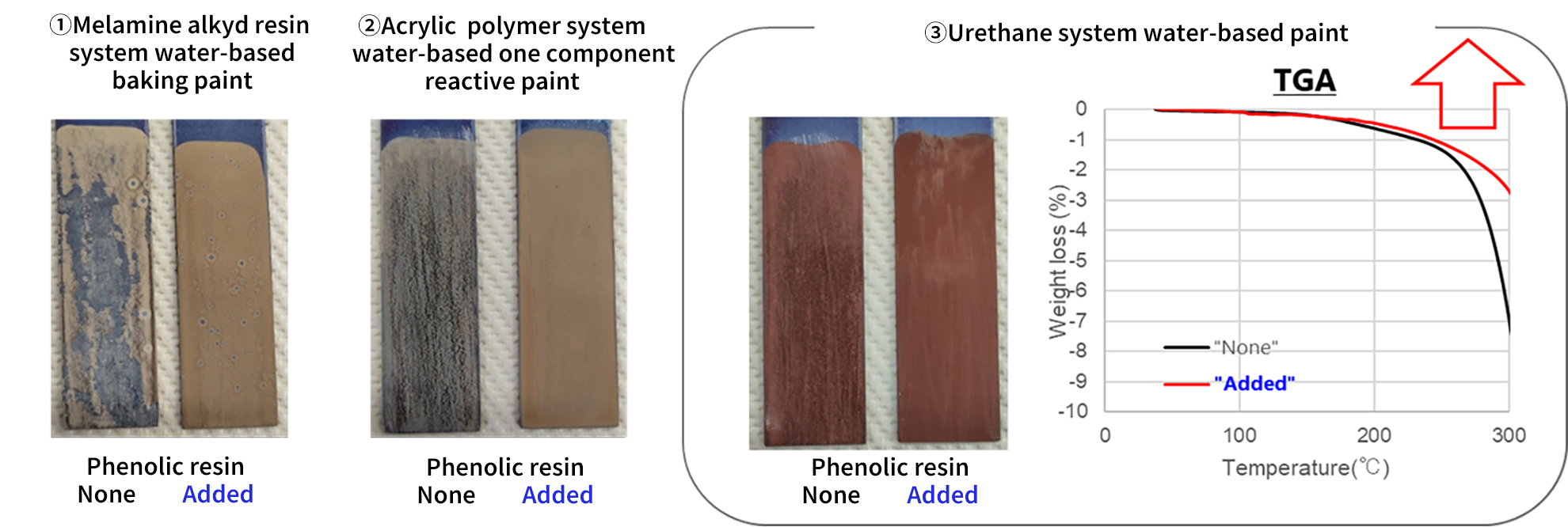

Heat resistance

After heat treatment for 4 days in 220°C hot air oven, and rubbed 30 times with a cloth soaked in acetone.

[ Measurement conditions ]

- The above 3 water-based paints were formulated by adding 10% of AQNOA™PR-56449.

- Coated by10–20 μm thickness using a bar coater on acid-washed steel plates degreased with acetone.

- Cured for 20 minutes in a hot air oven at 150°C.

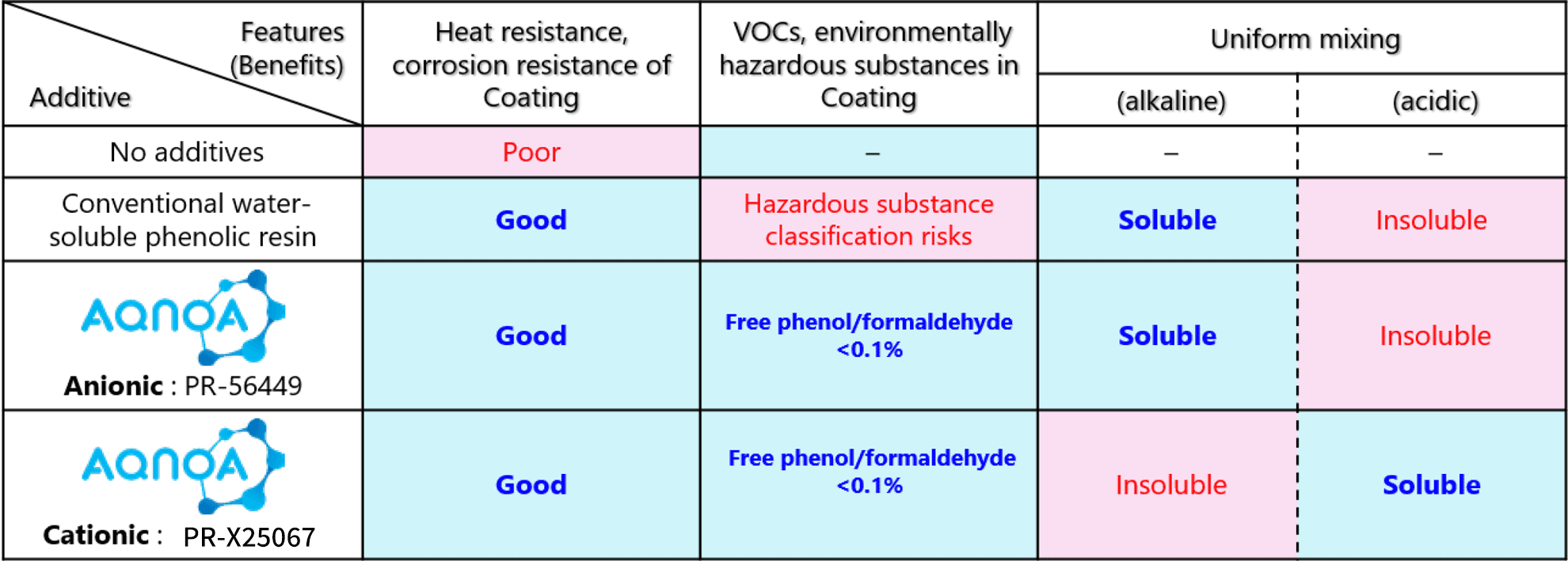

Advantages of AQNOA™

Conventional water-soluble phenolic resins contain high levels of phenol and formaldehyde, which may cause the added coating products to be classified as hazardous substances. However, as for AQNOA™, the phenol and formaldehyde content is less than 0.1%. We line-up both anionic and cationic types, enabling stable dispersion in various paint formulations.

Topics More

- 2026/01/30ProductsDevelopment of Biomass PFA Resin-Based Prepreg with Superior Flame Retardancy for Aircraft Interior Materials

- 2026/01/15ProductsAdoption of Heat-Dissipating Insulating Sheet in Resin-Insulated Substrate Integrated Power Module

- 2026/01/13ProductsSustainability Topics: Launch of the Website Towards the Sustainability of Phenolic Resins

- 2026/01/13ProductsInitiatives for Mechanical Recycling of Phenolic Resin Products

- 2025/11/13ProductsLaunch of Mass Production of the Main Deck Cargo Liner for Airbus' New A350F Freighter Aircraft

Inquiry

Inquiry