June 16, 2025

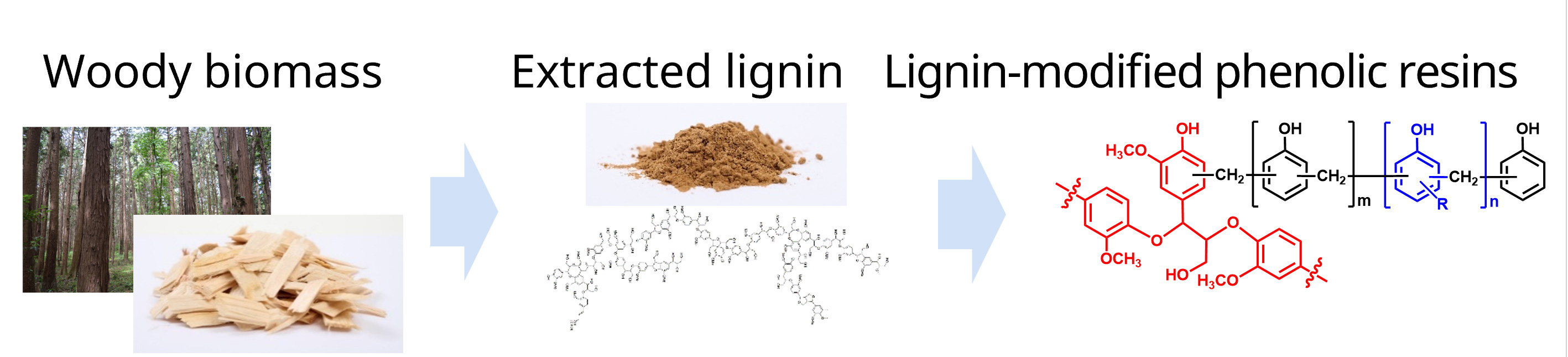

Tokyo, Japan – June 16, 2025, Sumitomo Bakelite Co., Ltd. (TOKYO: 4203 HQ: Shinagawa-ku, Tokyo, President and Representative Director: Kazuhiko Fujiwara) announces the launch of commercial sales of solid Novolac-type lignin-modified phenolic resin utilizing lignin extracted from non-edible biomass. Phenolic resins are roughly classified into liquid Resol and solid Novolac-type. Solid Novolac-type lignin-modified phenolic resin is widely used in the automotive sector.

This is the first commercialization of solid Novolac-type lignin-modified phenolic resin in the world. Going forward, we aim to achieve a sustainable society by contributing to GHG (greenhouse gas) reduction and resource circulation by increasing the biomass rate and developing further applications.

* This product is based on research results of a project commissioned by the New Energy and Industrial Technology Development Organization (NEDO).

Development Background

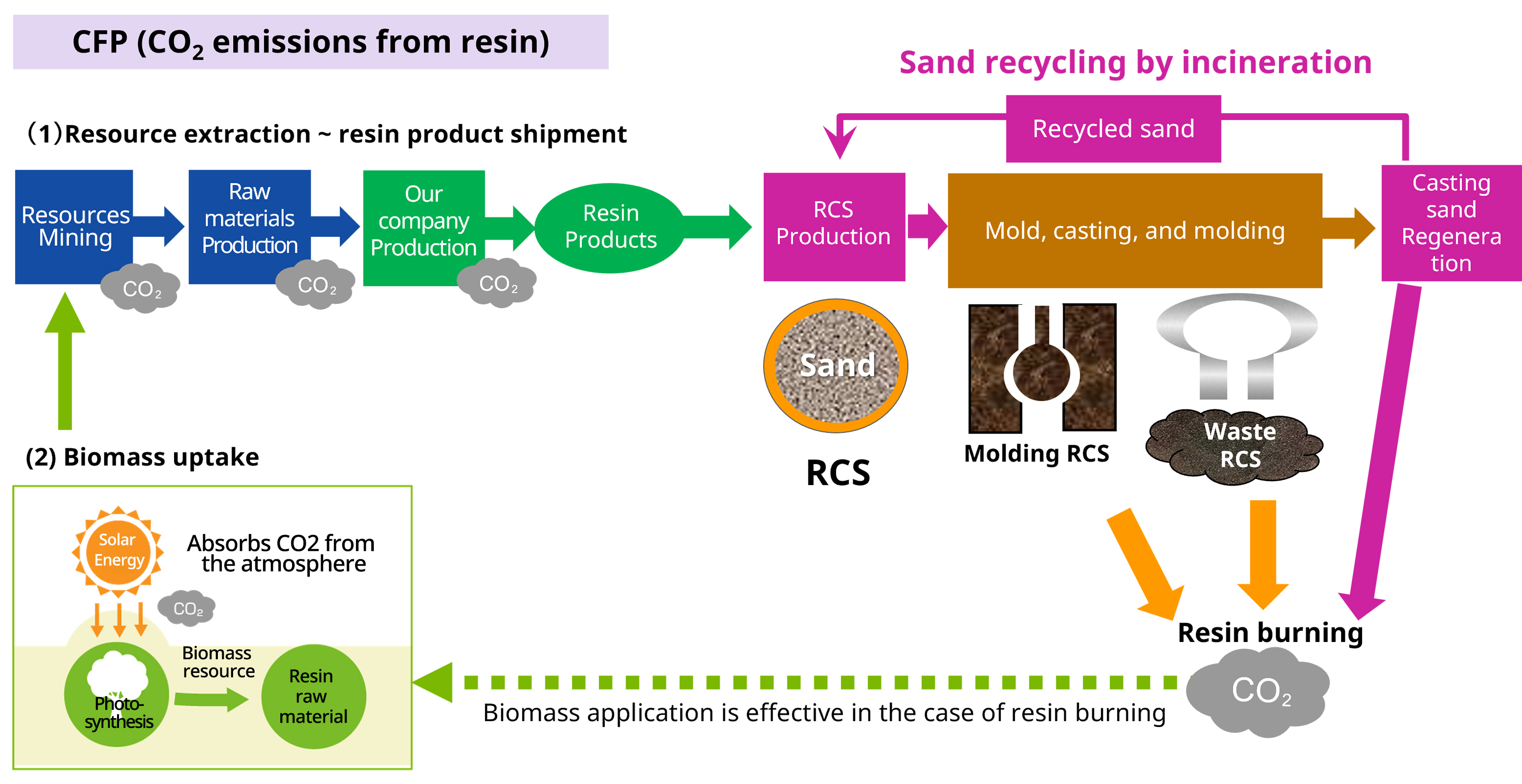

In recent years, there has been a growing interest in the environmental impact of plastics, and specific efforts to resource circulation and reduce GHG emissions are required in all industries. Recycling of plastic is effective when plastics cannot be replaced in terms of function. However, it is difficult to recycle materials used in applications that will eventually undergo combustion or wear, or in applications expected to have a long product life. In such cases, it is considered effective to convert raw materials derived from fossil resources to renewable biomass-based materials.

About Solid Novolac-Type Lignin-Modified Phenolic Resin

|

We have been actively engaged in research and development focusing on both biomass and recycling technologies of phenolic resin to minimize environmental load. Due to their exceptional heat resistance in the plastics industry, phenolic resins are often utilized in demanding applications, particularly in situations where they may be subject to wear or combustion during or after use. In such applications, recycling poses significant challenges, making biomass utilization a highly effective alternative. Since before 2010, we have been conducting foundational research on the potential use of lignin components as a promising biomass material for phenolic resins. Furthermore, through our participation in a project commissioned by the New Energy and Industrial Technology Development Organization (NEDO), we have been advancing the development of resin synthesis and material technologies leveraging various types of lignins. To accelerate the early and steadly social implementation of diverse extracted lignins, we have established a mass production system for lignin-modified phenolic resins, utilizing lignin derived from the pulp production process — a by-product of the pulp and paper industry. This effort led to the world’s first commercial sales of the solid Novolac-type lignin-modified phenolic resin. Among these products, SUMILITERESIN PR-L-0002 has been adopted by RCS (resin coated sand) manufacturers as a binder resin. Since early 2024, The RCS using PR-L-0002 has been utilized by automotive manufacturers in the production of certain cast parts for vehicles. |

|

- Appropriate utilization of diverse lignins in phenolic resins

- Early social implementation using commercialized lignin derived from pulping production Solid novolak-type lignin-modified phenolic resin-type lignin-modified

Features of this product

Many studies have been conducted on liquid Resol type lignin-modified phenolic resins obtained under alkali catalysis, since various extracted lignins are soluble in alkali, and social implementation of adhesives for wood materials is progressing recently.

Last year, our group (SUNBAKE) also commercialized the “SUMITAC® PL-700 Series,” which replaces biomass-derived lignin as a phenolic resin adhesive used in the production of plywood and laminated veneer lumber.

On the other hand, solid Novolac-type lignin-modified phenolic resins produced under acid catalysis face challenges in application due to the difficulty of melting and dissolving lignin, resulting in limited progress in their social implemention. However, we successfully demonstrated ton-scale mass production in 2019 and has since been actively working towards expanding its applications by offering samples and conducting trial sales. *1

*1 Development of plant-derived (solid Novolac-type) phenolic resin (lignin-modified phenolic resin)

Commercialization example: Application of PR-L-0002 to casting RCS binder resin

- The RCS binder resin is incinerated during sand regeneration. PR-L-0002 is same performacne and does not hinder the sand regeneration process as same as conventional high strength RCS binder resin (refer to figure).

- PR-L-0002, features a biomass ratio of 15%, enabling a 15% reduction in fossil resource consumption compared to existing products. Additionally, it achieves an 11% reduction in carbon footprint (CFP).

- We’re developping to achieve a biomass ratio exceeding 30% for high-strength RCS binder resins, as well as for other potential applications.

Future Plans

|

Solid Novolac-type phenolic resins are widely utilized across various applications, particularly in the automotive industry, including molding materials, friction materials, and tires—areas of expertise for us. With the commercialization of this product, we aim to further broaden its applications to automotive components and various binders, driving the social implementation of diverse lignins and advancing the sustainability of phenolic resins. |

|

For details of NEDO (New Energy and Industrial Technology Development Organization) projects, please refer to our website.

˙ Green Sustainable Chemical Process Infrastructure Technology Development (FY 2010-2012)

˙ Non-edible Plant Chemicals Production Process Technology Development (FY 2013-2019)

Calculation of CFP in Resin Production

| Mass production scale | Lignin-Modified Phenolic Resin | Cont. Phenolic resins derived from fossil resources |

|---|---|---|

| Resin composition | Lignin/phenol | Phenol |

| Biomass rate1) (%) | 15 | 0 |

| CFP (emissions from manufacturing) (kg-CO2eq/kg) | 3.06 | 3.02 |

| CFP (biomass absorption)2) (kg-CO2eq/kg) | 0.36 | 0 |

| CFP (total) (kg-CO2eq/kg) | 2.70 | 3.02 |

| CFP reduction rate vs. control (%) | -10.7 | 0 |

| CFP reduction amount vs. control (kg-CO2eq/kg) | 0.32 | 0 |

Conditions for CFP Estimation in Resin Production

- Database: IDEA v2.3

* Note: Primary raw material, lignin, data collected from supplier inputs. - Impact Area: 100-year index (IPCC, 2013)

- Characterization Model & Target Item: Climate change

- System Boundary: From raw material extraction to resin shipment

- Production Facility: Sumitomo Bakelite Co., Ltd., Shizuoka Plant

- Data Collection Period: April 2022 – March 2023

| 1) | The biomass ratio is calculated as the proportion of biomass-derived raw materials contained in the resin product. |

|---|---|

| 2) | The biomass absorption amount is estimated based on the assumption that CO2 in the atmosphere is fixed as biomass carbon. |

| 3) | The above values are representative figures and are not guaranteed. |

Notes:

- This calculation is based on the information available at the time of estimation and does not guarantee its validity in the future.

- As no certifications or official approvals have been obtained, please treat these values as reference data only.

Related Information

[Contact information]

Materials Solution Sales Division, Sumitomo Bakelite Co., Ltd.