Overview of product

|

A new phenolic resin by using non-edible biomass which has comparable high strength and heat Resistance to oil-based phenol resinsThe product is produced by using Lignin which is non-edible biomass. Lignin modified resin shows comparable workability and performance to conventional oil-based phenol resins. Furthermore the resin shows unique property in specific application. |

- *1: This development utilizes results obtained from a project commissioned by the New Energy and Industrial Technology Development Organization (NEDO).

Technical data

Solid novolak (flake)

| Item No. | Note | Biomass (%) |

Softening Poing (℃) |

Free Phenol (%) |

|---|---|---|---|---|

| PR-X20108 | Lignin modified | 25-40 | 125 | < 1.0 |

| PR-X20109 | Lignin modified | 25-40 | 117 | < 1.0 |

| PR-X21085 | Multi modified | 40-60 | 110 | < 1.0 |

|

Remark

|

solid novolak (powder)

| Item No. | Note | Flow 125℃, mm |

Gelation Time 165℃, sec |

Free Phenol (%) |

|---|---|---|---|---|

| PR-X20068 | Lignin modified | 12 | 29 | < 1.0 |

| PR-X20084 | Lignin modified | 22 | 26 | < 1.0 |

|

Remark

|

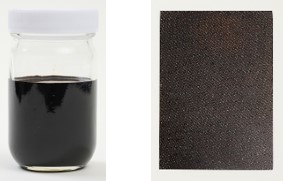

Liquid resole

| Item No. | Note | Viscosity mPas |

pH | Free Formaldehyde (%) |

Free Phenol (%) |

|---|---|---|---|---|---|

| PR-X20048 | Lignin modified | 500 | < 10 | < 0.1 | < 1.0 |

|

Remark

|

The above is an example. We propose resins suitable for each application.

Application

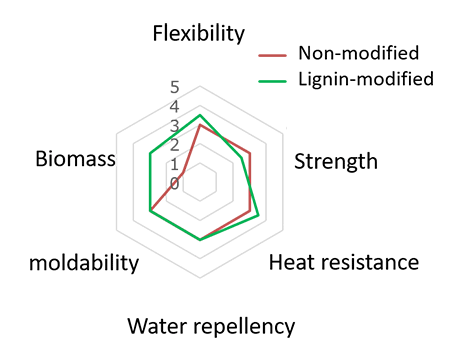

Friction material

✔ Flexibility ✔ High heat resistance |

|

Friction property

| Non-modified | Lignin-modified | |

|---|---|---|

| Porosity (%) | 17.1 | 17.2 |

| Hardness (HRR) | 77 | 53 |

| Flexural strength (r.t., MPa) | 34.8 | 24.0 |

| Flexural strength after 350℃ (MPa) |

2.3 | 2.7 |

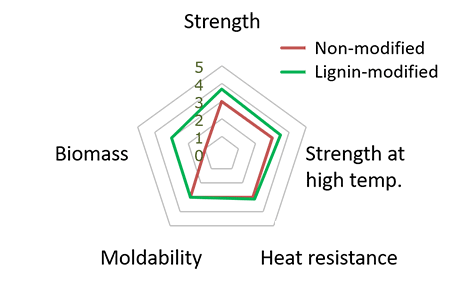

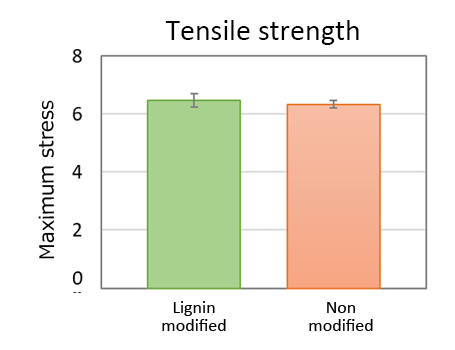

Molded material

✔ High strength ✔ High heat resistance |

|

Molded material property

| Non-modified | Lignin-modified | |

|---|---|---|

| Strength (Ratio) | 100 | 123 |

| Strength at high temp. (Ratio) | 100 | 117 |

| Impact resistance (Ratio) | 100 | 117 |

| Insulation resistance (Order) | 1011 | 1011 |

| Liner expansion (ppm) | 26 | 28 |

- The value is representative.

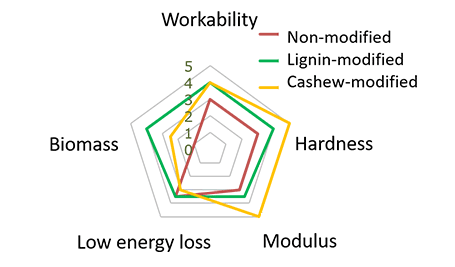

Rubber reinforcing

✔ Balanced property ✔ High biomass ratio |

|

Rubber (NR/CB) property

| Non-modified | Cashew-modified | Lignin-modified | |

|---|---|---|---|

| Biomass ratio (Ratio) | 0 | ~40 | 45~60 |

| Mooney viscosity (Ratio) | 100 | 90 | 90 |

| Hardness (Ratio) | 100 | 110 | 105 |

| Modulus ((Ratio) | 100 | 180 | 130 |

| Low energy loss (Ratio) | 100 | 85 | 100 |

- The value is representative.

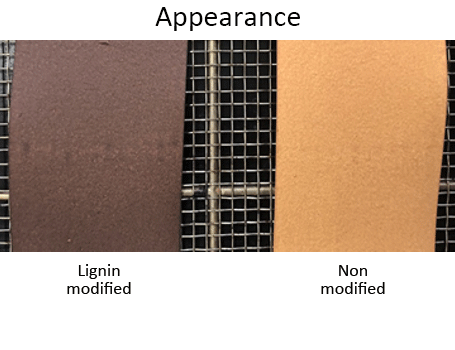

Impregnation

✔ Flame resistance ✔ High biomass ratio |

Glass cloth laminate property

| Non-modified | Lignin-modified | |

|---|---|---|

| Appearance | Light yellow | Dark brown |

| Impregnation | good | good |

| Burning test | V-0 | V-0 |

Impregnated paper property

|

|

✔ Comparable function to non-modified resole

Topics More

- 2026/01/30ProductsDevelopment of Biomass PFA Resin-Based Prepreg with Superior Flame Retardancy for Aircraft Interior Materials

- 2026/01/15ProductsAdoption of Heat-Dissipating Insulating Sheet in Resin-Insulated Substrate Integrated Power Module

- 2026/01/13ProductsSustainability Topics: Launch of the Website Towards the Sustainability of Phenolic Resins

- 2026/01/13ProductsInitiatives for Mechanical Recycling of Phenolic Resin Products

- 2025/11/13ProductsLaunch of Mass Production of the Main Deck Cargo Liner for Airbus' New A350F Freighter Aircraft

Inquiry

Inquiry