September 17, 2020

Tokyo, Japan –September 17, 2020 Sumitomo Bakelite Co., Ltd. (TOKYO: 4203 HQ: Shinagawa-ku, Tokyo, President and Representative Director: Kazuhiko Fujiwara) has developed solid novolac phenolic resins using "lignin" which is a major component in plants and successfully demonstrated manufacturing on mass production machines by establishing production technologies which was a challenge we had to tackle. We will be distributing thermoset environment responsive plastic to various fields starting with our staple automobile field.

Development Background

Our main product, phenolic resins, is manufactured using petroleum as its raw material, and it is thought that resource conversion using plant resources such as non-edible biomass that do not compete with foods is required to cope with future global issues including supply risks of petroleum resources due to future population growth and reduction of greenhouse gas as a countermeasure to tackle climate change.

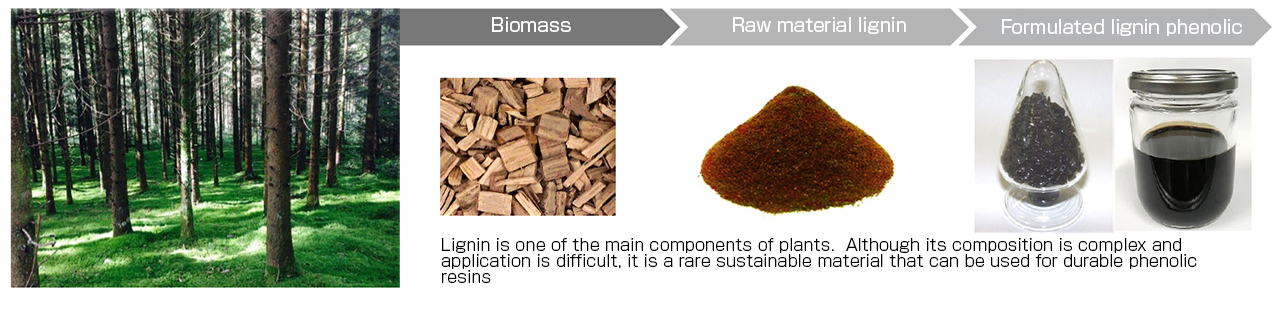

Along with hemicellulose and cellulose, lignin is one of the three major components that constitute plants, and plays an important role as a binder that applies physical strength and chemical stability to plant cells. Due to a limitation in convertible resources of petroleum-derived aromatic raw materials in recent years, it is expected for lignin, which is known as a natural phenolic polymer with an abundant amount of aromatic organic resources, to be used for heat-resisting aromatic resin as a renewable resource.

With expectations in a rise in environment responsive needs for phenolic resins, our staple product, we have been performing resin development to create a core technology for synthetic resins using a variety of lignin and prepare it for industrial use through base research for resin use of lignin components before 2010 as well as participating in the “Development of Fundamental Technologies for Green-Sustainable Chemical Processes (2010 - 2012)” and “Technology Development of Manufacturing Processes for Non-edible Plant-derived Chemicals (2013 - 2019)”* which are commissioned projects for New Energy and Industrial Technology Development Organization (NEDO).

Developed Products

|

Research for liquid resol type lignin modified phenolic resins has been conducted since long ago, and in recent years, it has been applied to products such as wood adhesives mainly in Europe. In addition to liquid resol type resin, we have developed solid novolac type lignin modified resins, which is difficult in terms of production processes and established mass production of the resin. We have continued to examine its practical use based on knowledge from base research, achieving a material that is comparable with existing petroleum-derived phenolic resins in terms of formability, resin material characteristics, and cost. Resin design of over 50% is possible in terms of biomass rate depending on its use. Through development of novolac type Lignin modified phenolic resins, it is now applicable in phenolic resins material fields starting with the automobile field, which is our main business. |

Solid Novolac Type lignin modified phenolic resins |

Process of Lignin modified phenolic resins Manufacture

Lignin modified Novolac and Expected Uses (Molded Products)

As with petroleum-derived phenolic resins, it can be adjusted to resin characteristics based on its application. In addition to its superior rigidity and heat-resistant qualities similar to petroleum-derived resins, certain functions that derive from lignin can be achieved.

Future Developments

To respond to various needs in the market considering use of plant resources such as non-edible biomass, we are expanding applications to each industrial field both domestically and internationally, aiming for application in phenolic resins material used in various industrial fields starting with components for the automobile and aeronautics industries, where demand for environment response is high, as well as achieve actual results.

By realizing a manufacturing process for phenolic resins products that use non-edible biomass which are renewable raw material with cost competitiveness and reducing emission of carbon dioxide, we aim to constructing an industrial base that can achieve a sustainable low carbon society as well as contributing to the realization of SDGs.

New materials including this developed product are scheduled to be exhibited at Chemical Material Japan 2020 ONLINE.

- Chemical Material Japan 2020 ONLINE

October 19, 2020 (Mon) - November 18, 2020 (Wed) 10:00 - 17:00

https://www.chemmate.jp/en

* For details on commissioned projects for New Energy and Industrial Technology Development Organization (NEDO), refer to the NEDO webpage.

- "Development of Fundamental Technologies for Green-Sustainable Chemical Process (2010 - 2012)"

https://www.nedo.go.jp/activities/EV_00035.html - "Technology Development of Manufacturing Processes for Non-edible Plant-derived Chemicals (2013 - 2019)"”

https://www.nedo.go.jp/activities/ZZJP_100058.html

Related Information

For inquiries on this product:

Sumitomo Bakelite Co., Ltd., High Performance Plastic Products Business Unit Polymers Sales Dept.

Tel: +81-3-5462-4115 E-mail: info@sumibe.co.jp