Products

|

High heat resistant plastic with excellent Tribological performance and non-melt property

It is a phenolic molding compound with low friction coefficient and low wear

due to the high ratio of graphite. |

Features

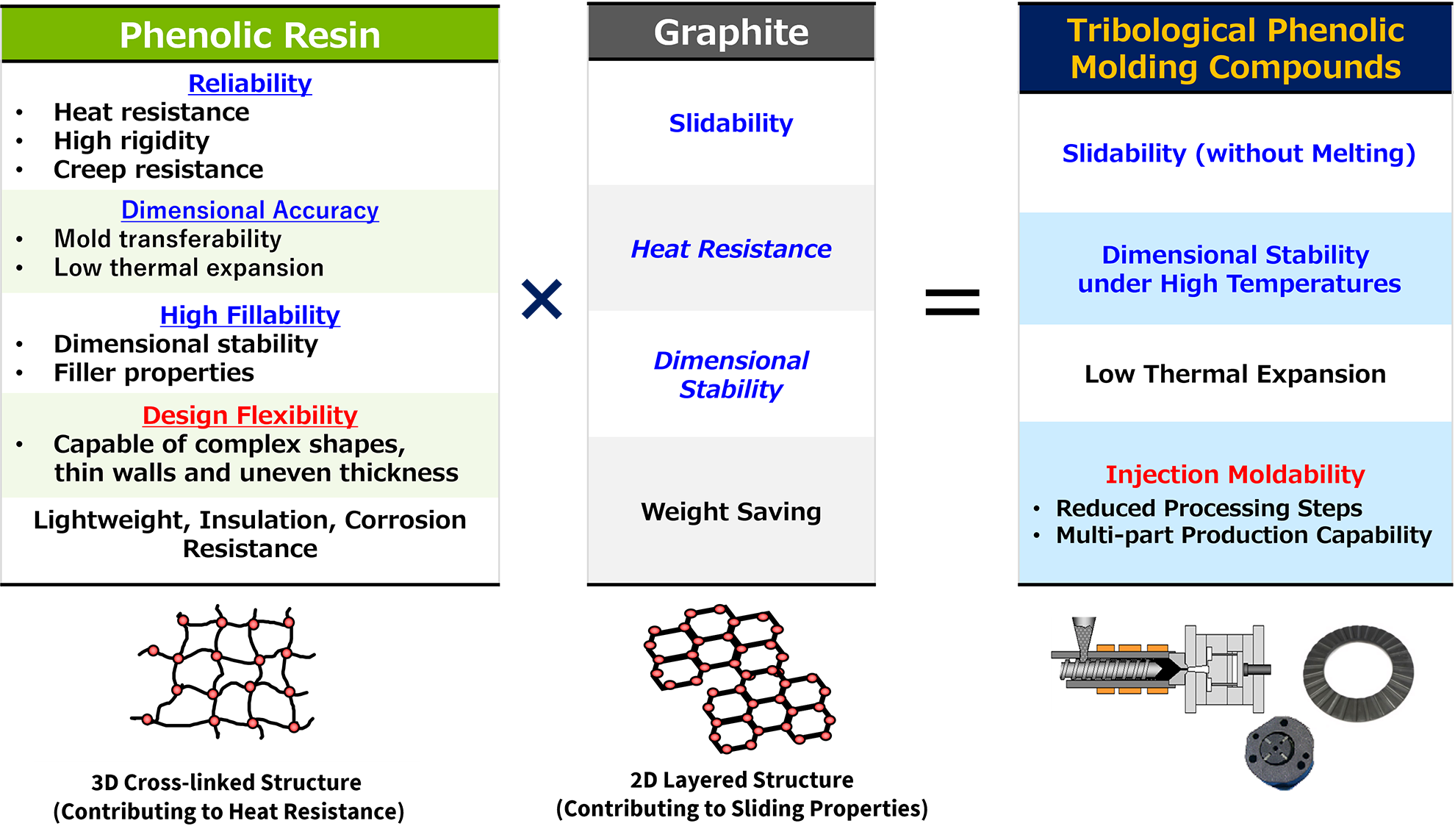

Phenolic molding compounds can contain more than 50% of inorganic fillers such as graphite, giving them the properties of these fillers.

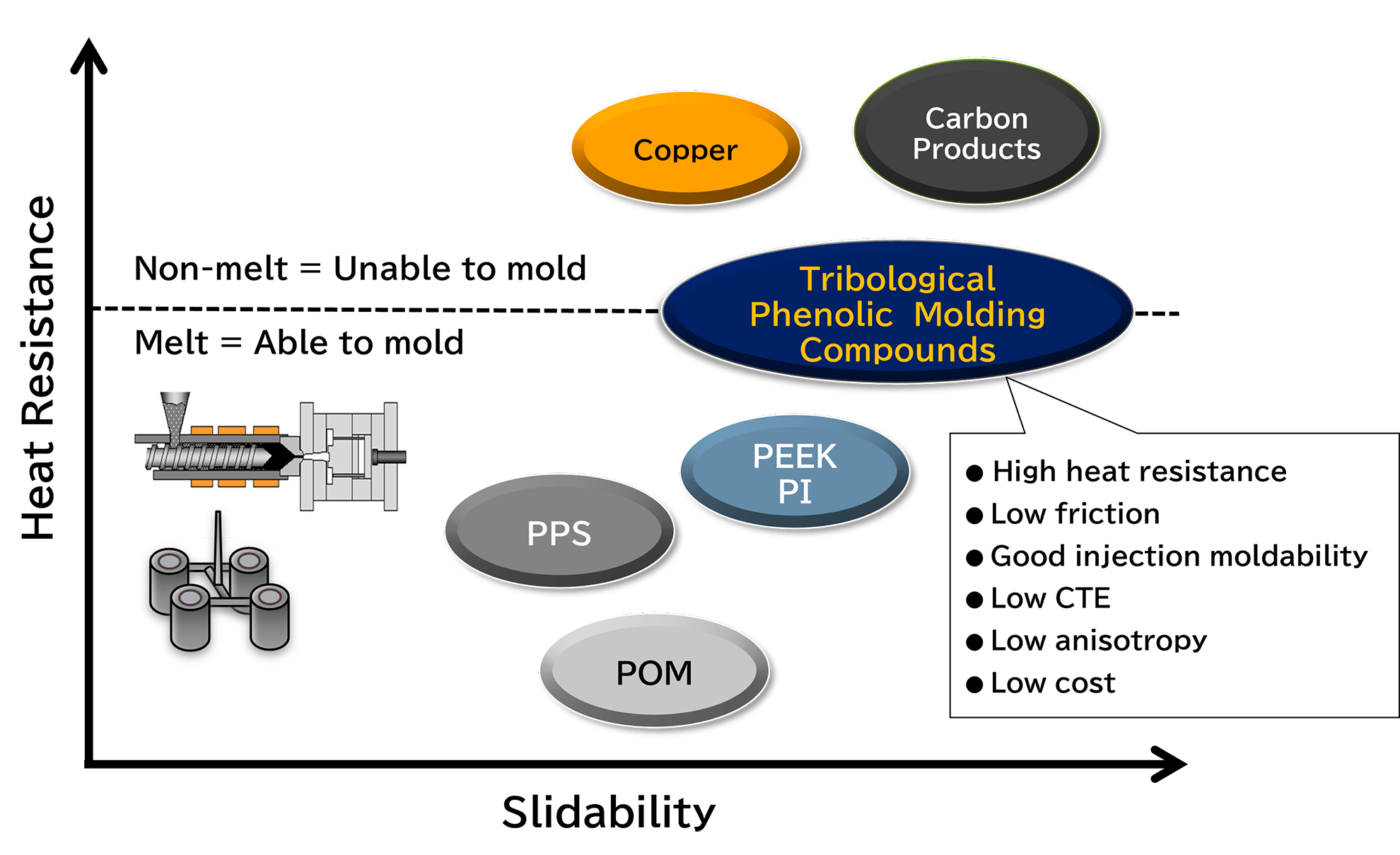

Positioning of material

This material melts during molding and becomes a cured product through a crosslinking

reaction. After

curing, it no longer melts.

This material offers heat resistance and various shape availability due to molding.

Applications

Below applications are required sliding and heat resistance properties.

- Vane type small pump

- Plane bearing for electric water pump

- Plane bearing for water pump of dish washing machine

- Seal ring

- Thrust washer

- Gas meter (Valve and Distribution chamber)

Technical data

Properties

| Item | Unit | Phenolic molding compounds | Sintered carbon |

PEEK Thermo- plastic |

|||

|---|---|---|---|---|---|---|---|

| PM-5750 | PM-5740 | PM-5780 | PM-5640 | ||||

| Low friction Low wear |

Low friction | Low friction Low warpage |

Low friction High strength |

||||

| Specific gravity | - | 1.67 | 1.65 | 1.61 | 1.78 | 1.77 | 1.45 |

| CTE | ppm/K | 20 | 22 | 25 | 21 | 23 | 45 |

| Flxeural strength | MPa | 90 | 90 | 90 | 180 | 75 | 230 |

| Flxeural modulus | GPa | 13.5 | 13 | 12 | 15 | 15 | 11.5 |

| Compressive strength |

MPa | 160 | 160 | 150 | 300 | 175 | 170 |

| Frictional coefficient (0.6Mpa, 5m/s) |

- | 0.10 | 0.12 | 0.12 | 0.20 | 0.14 | 0.23 |

| Comparative abrasion quantity |

mm/ (MPa・m/s・hr) |

2×10-3 | 3.5×10-3 | 5×10-3 | - | - | - |

| Tg | °C | 200< | 200< | 200< | 200< | - | <150 |

Notes

- The above data is for reference only. For phenolic molding compouds, test piecies are prepared by injection molding, and tested according to ISO standards after annealing.

- Abrasion tests are tested with S45C.

Sliding performance

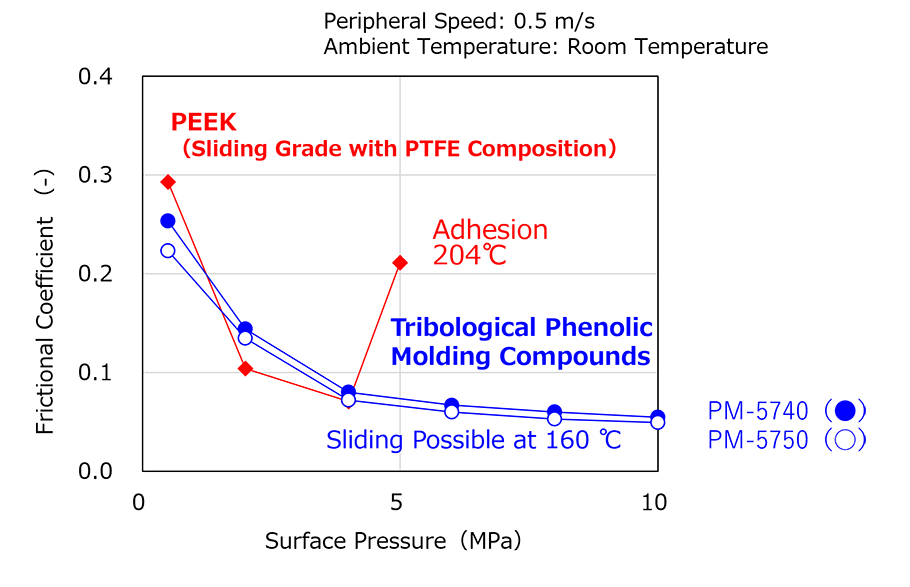

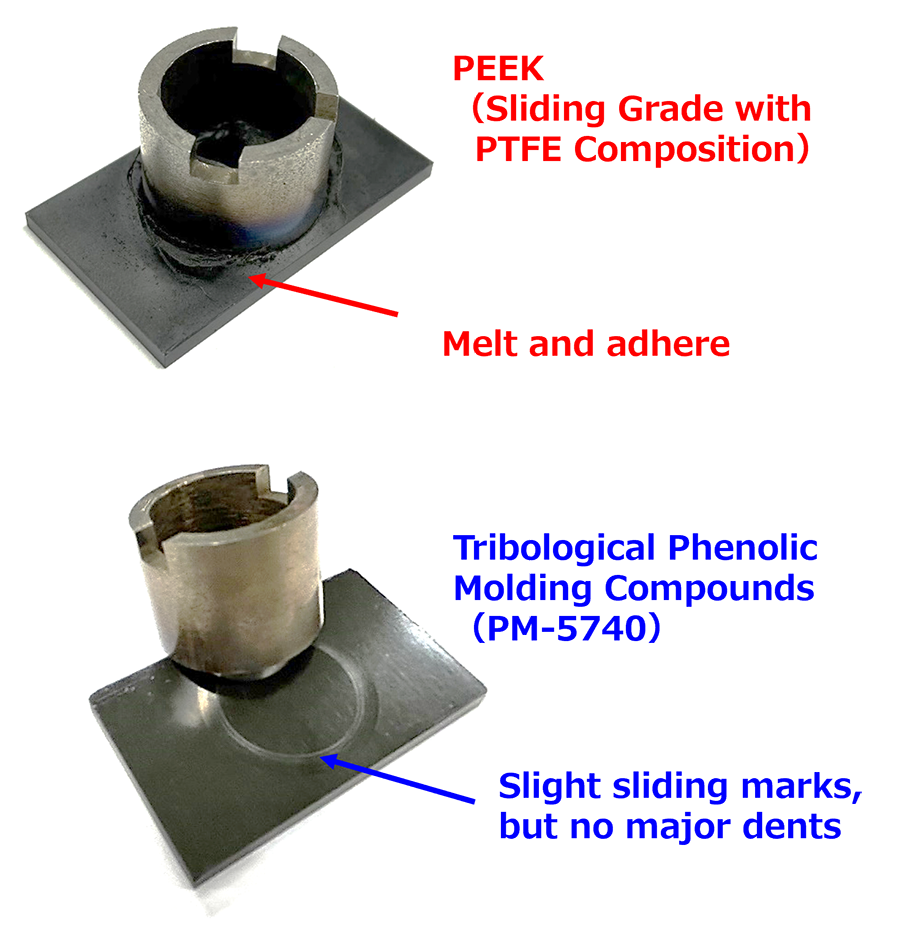

Metal ring (S45C) is rotated on the plastic plate, loading with surface pressure.

Under high PV condition, PEEK got melted and sticked, and frictional resistance increased.

Tribological Phenolic Molding Compounds can keep excellent friction & stable μ also under high PV condition.

Topics More

- 2026/01/30ProductsDevelopment of Biomass PFA Resin-Based Prepreg with Superior Flame Retardancy for Aircraft Interior Materials

- 2026/01/15ProductsAdoption of Heat-Dissipating Insulating Sheet in Resin-Insulated Substrate Integrated Power Module

- 2026/01/13ProductsSustainability Topics: Launch of the Website Towards the Sustainability of Phenolic Resins

- 2026/01/13ProductsInitiatives for Mechanical Recycling of Phenolic Resin Products

- 2025/11/13ProductsLaunch of Mass Production of the Main Deck Cargo Liner for Airbus' New A350F Freighter Aircraft

Inquiry

Inquiry