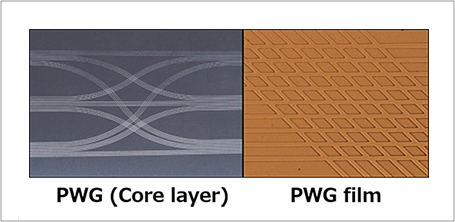

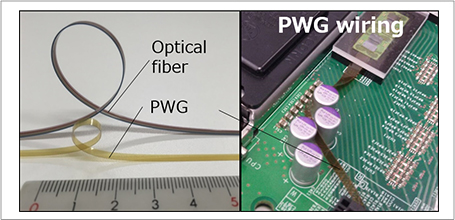

A flexible optical circuit film with low optical propagation loss and low crosstalk that uses our company's original polymer material and unique manufacturing method. Our company processes films to meet customer needs.

Multi-core optical signal

For optical fiber

[Reference] Wiring pitch 250 μm (Core Φ 50 μm) |

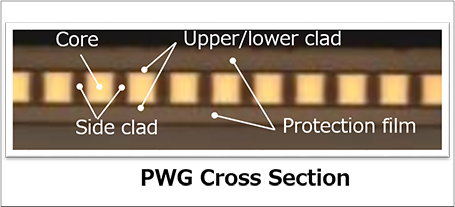

For polymer waveguide (PWG)

[Reference] Wiring pitch 60 μm (Core width 48 μm)

Long distance transmission from waveguides ↓

|

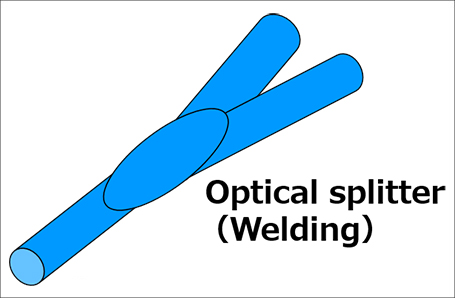

Branching of optical wiring

For optical fiber

|

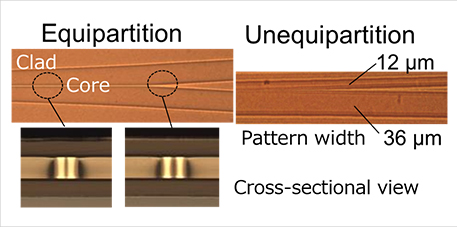

For polymer waveguide (PWG)

[Reference] Light intensity ratio 1:9, 2:8, 3:7, etc. |

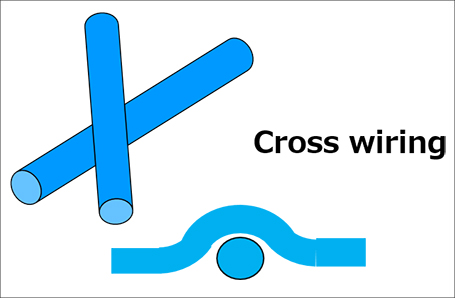

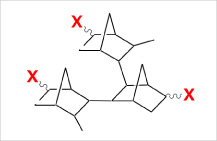

Optical cross wiring

For optical fiber

|

For polymer waveguide (PWG)

* Please contact us directly for detailed design conditions. |

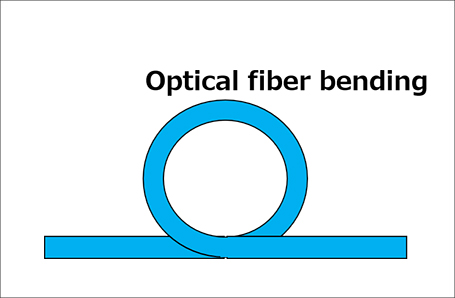

Optical wire bending

For optical fiber

|

For polymer waveguide (PWG)

|

![Scalable Fiber Shuffle [Sumitomo Electric]](images/img009.jpg)

Inquiry

Inquiry FAQ

FAQ