Policy and Basic Approach

Environmental Policy

Our Group has established the Environmental Policy as a policy related to environmental issues pertaining to our Group (including reduction of greenhouse gas (GHG)). Our Group’s Environmental Policy is described on the following page.

Group Environmental Vision for 2050

Our Group relies upon using the earth’s natural resources, water, and energy in order

to continue to do business. Furthermore, we also emit chemicals such as CO2, NOx, and SOx

into the

atmosphere and produce waste water and waste materials as a result of our business activities. For this

reason, we conduct our business activities while working to minimize the impact they place on the

environment and pursue initiatives that provide environmental and social values through the products and

services that we create.

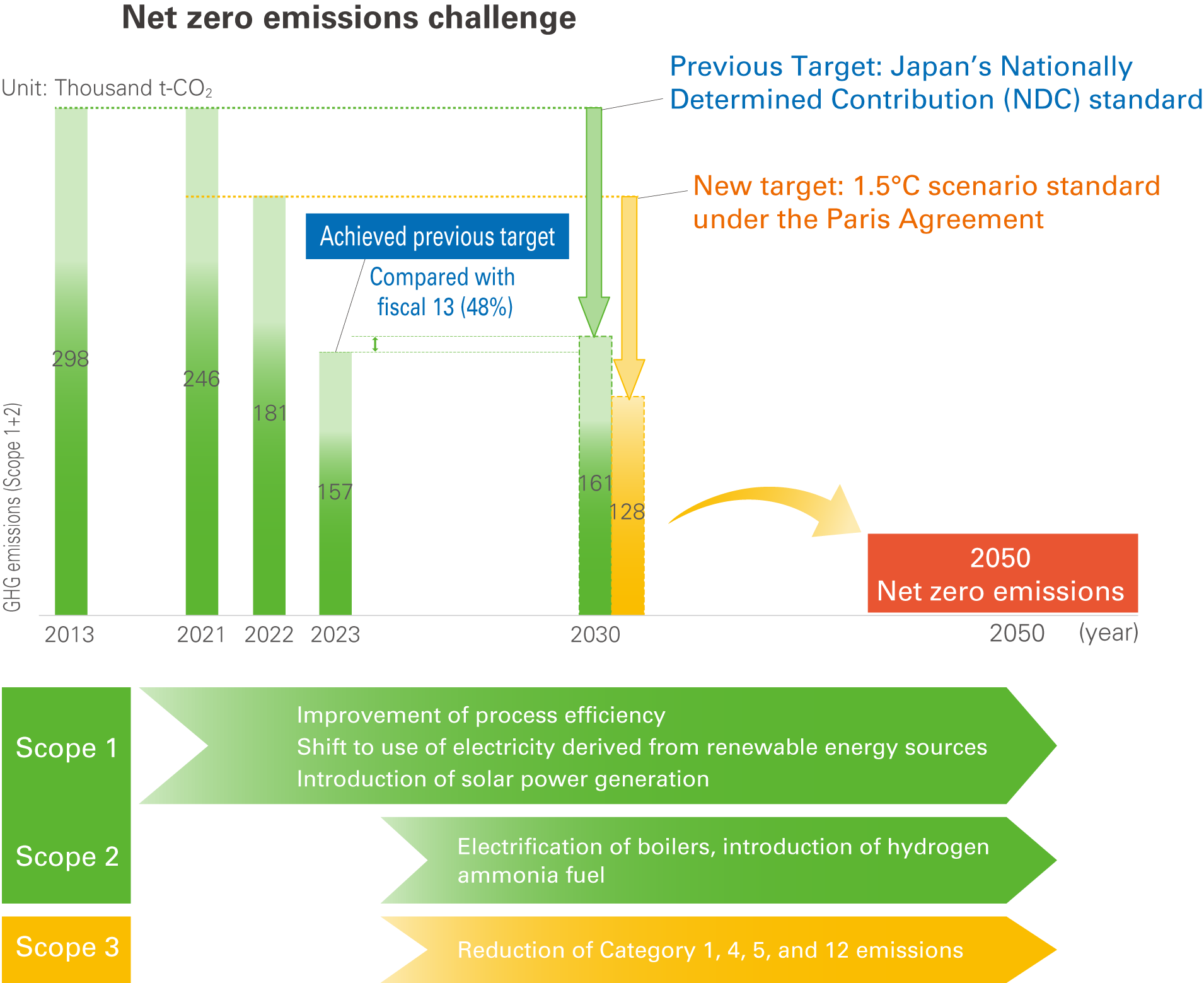

Our Group has created the Environmental Vision for 2050 which focuses on the

particularly important problem of reducing GHG emissions. In FY2025, we set a target for 2030 consistent

with the 1.5°C scenario standard, and adopted initiatives (Scope 3) throughout our entire supply chain.

Moving forward, we will further expand these initiatives with the aim of achieving carbon neutrality by

2050.

● Trends in GHG Emissions Toward Becoming Carbon-Neutral

| 2050 Target | Achieving carbon neutrality | |

| 2030 Target | GHG emissions (compared to FY2021) | |

| Scope 1+2 | 48% or more reduction | |

| Scope 3 (Categories 1, 4, 5, 12) |

25% or more reduction | |

Note that the 2030 GHG emissions reduction target adopted by our Group was certified as a scientifically grounded target by the Science Based Targets initiative (SBTi).

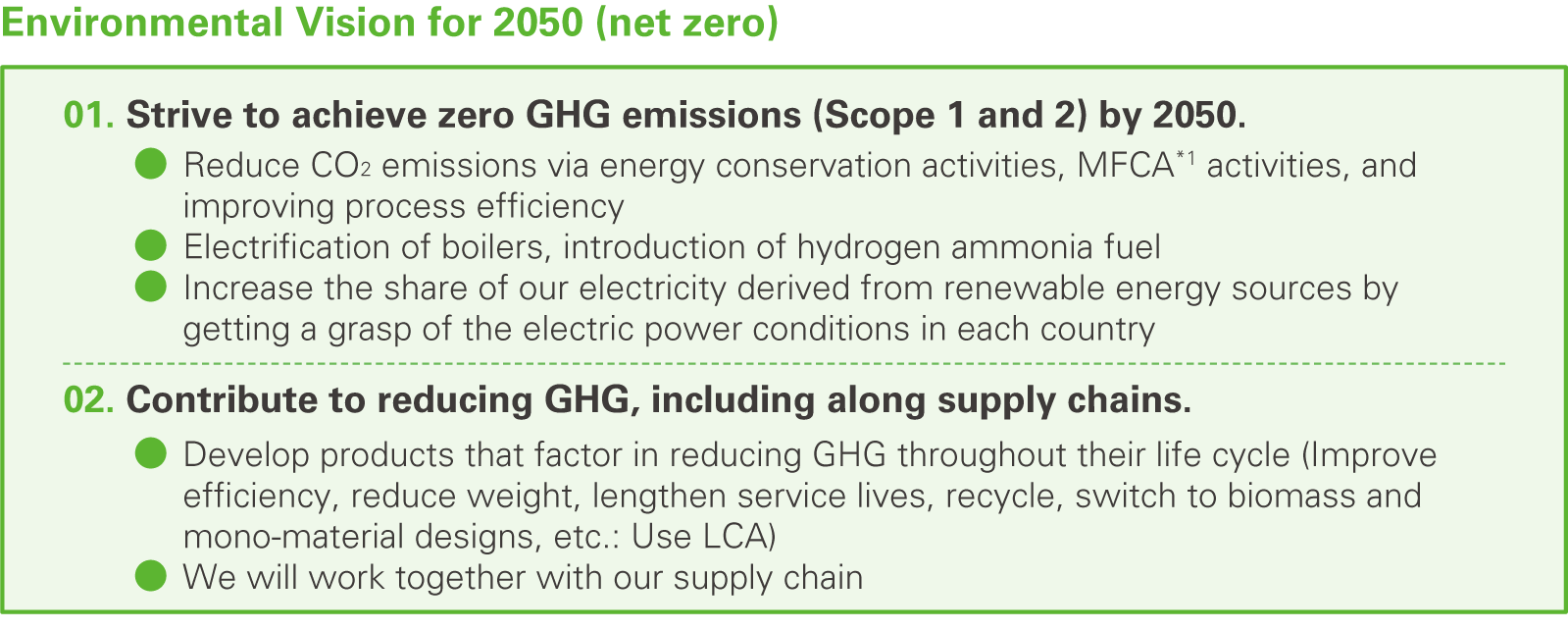

Environmental Vision for 2050

01. Achieving carbon neutrality by 2050 in relation to GHG emissions (Scope 1 and 2).

● Reduce GHG emissions via energy conservation activities, MFCA*1 activities, and improving process efficiency

● Electrification of boilers, investigation of introduction of hydrogen and ammonia fuel

● External procurement of electricity derived from renewable energy sources

● Investigate introduction of negative emission technologies such as CO2 absorption

02. Contribute to reducing GHG emissions, including along supply chains.

● Develop products that factor in reducing GHG emissions throughout their life cycle

● Work in cooperation with supply chain

- *1 An abbreviation of Material Flow Cost Accounting, which is a method of environmental management accounting that aims to pursue both reduction of environmental impact and cost reduction at the same time. Our Group uses it as an analysis method.

Systems (Governance)

The systems for supervision and management of environmental issues pertaining to our Group (including reduction of GHG) are described on the following page.

Risk Management

The identification, assessment, and management of risks and opportunities related to environmental issues pertaining to our Group (including reduction of GHG) are carried out in accordance with the risk management structure and risk management processes described on the following page.

Metrics and Targets

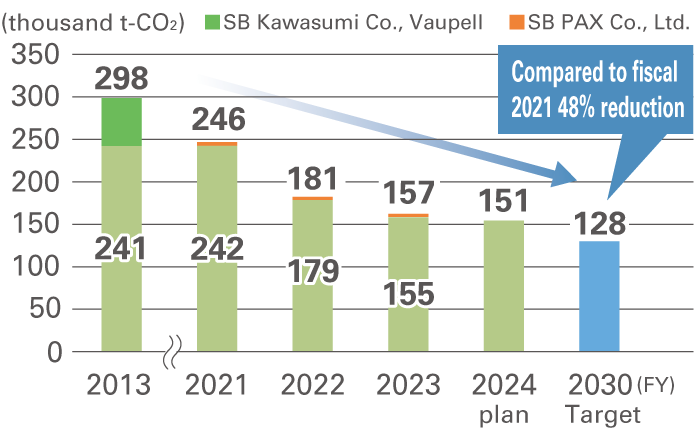

Reduction of GHG emissions

Our Company is promoting activities to reduce GHG based on the “near-term 1.5°C target” as certified by

the SBTi.

We have announced “48% or more reduction compared to FY2021” as our reduction target for GHG emissions

(Scope 1 + Scope 2) by 2030.

We are making progress on our reductions towards the 2030 target, with emissions in FY2024 of 135 thousand

t-CO2, which is a 45% reduction compared to FY2021.

● CO2 Emissions (Scope 1 + Scope 2): Group of Sumitomo Bakelite Co., Ltd.

- *1. The scope of aggregation covers Sumitomo Bakelite Co., Ltd. and its consolidated subsidiaries.

- *2. The methods for defining and calculating GHG emissions are described in Detailed Data Related to Sustainability (Environment).

Our Group has selected creation of environmental and social value as one of “our Group’s material issues”, and set the GHG emissions reduction as a KPI.

Key Initiatives

Activities of the Carbon Neutrality Promotion Committee

The Carbon Neutrality Promotion Committee recaps each year’s progress toward medium- to long-term environmental targets at the end of the fiscal year and determines the targets for the following fiscal year. It carries out its activities with the approval of the Sustainability Promotion Committee, which serves as its parent body. Two subcommittees were established within the committee in order to achieve its objectives, and these subcommittees work to reduce our environmental impact.

The Life Cycle Subcommittee aims to establish production systems with minimal environmental impacts through scientific, quantitative, and objective assessments of environmental impacts, from the R&D phase onward.

With the global trend toward achieving carbon neutrality, the approach to LCA (Life Cycle Assessment)—which assesses products over an extended period of time from their raw materials through to use and disposal—has become indispensable, and “LCA” has become a common term when engaging in dialogue with customers and suppliers.

In light of these circumstances, to provide an opportunity to learn about the fundamentals of the social background of LCA, the basics of LCA methods, and our initiatives, the LCA Basics e-learning course was arranged starting from FY2023 for employees under the jurisdiction of the head office, with 1,277 employees taking the course in FY2024.

Each R&D department decides a theme and works on it with an awareness of LCA, from raw material extraction to final disposal (Cradle to Grave). In FY2024, we worked toward the target of “retaining at least at 25% of all researchers” as qualified R&D personnel capable of understanding LCA and calculating the carbon footprint (CFP) of products. To this end, we organized LCA introductory courses, LCA training courses and LCA practice courses (comprehensive education and tutorials related to LCA) online, and maintained a target of 34% in FY2024. Starting from FY2023, guidance officers were also selected from qualified personnel for each location, to boost the level of LCA initiatives at each location. In FY2025, we will continue to offer a full set of education opportunities and strive to retain 25% of qualified researchers.

In addition, we also formed a plan to establish a system that would enable us to speedily provide LCA information (able to provide within seven business days when a request to submit CFP data is received), from raw material extraction to factory gate (Cradle to Gate), on all of our Group’s products by the end of FY2024, in response to the rapid increase in inquiries from customers regarding LCA since the Japanese government’s October 2020 net zero greenhouse gas emissions declaration. This system was fully implemented at all of our domestic and overseas plants by the end of FY2024.

The CN Technology Review Subcommittee has established a system for continuously soliciting and implementing energy conservation ideas, and is promoting voluntary energy conservation activities at domestic sites.

In FY2024, the subcommittee successfully reduced energy consumption by as much as 2,461 kL (95,399 GJ) in crude oil equivalent, or 4,542 t-CO2, compared with FY2023, primarily by reducing city gas and electricity consumption. Outside of Japan, the subcommittee worked to ensure a similar level of activities as in Japan and continued to promote the roll out of activity methods and best practices. Furthermore, as part of our work toward CN, which is one of our 2050 targets as described earlier, we began from January 2022 switching the electricity we purchase at all our main business sites in Japan to electricity derived from renewable energy sources, and we will continue those contracts into the future. Our overseas Group companies are also pursuing changing to electricity derived from renewable energy sources.

In FY2025, in line with the objectives of the CN Promotion Committee, the CN Technology Review Subcommittee will formulate a plan and work toward the most recent 2030 target. In terms of energy conservation, we will build upon past efforts to set energy conservation targets and also to complete our reduction plans for each business site. In particular, the subcommittee will focus on creating a system across business sites in Japan for sharing energy conservation practices and technical information related to energy conservation in order to improve the level of energy-saving technology throughout our Company; and having the mother plants in Japan provide technical support to their affiliated sites through a tie-up with the Company-wide Energy Conservation Secretariat.

Climate change program efforts, TCFD initiatives, and participation in GX League

CDP*1 (headquartered in London) is an international NGO established in 2000 in partnership with institutional investors from around the world. It carries out projects in which it sends out questionnaires to major companies and municipal governments around the world on issues such as climate change, water security, and forests, and that seek climate change strategies and specific declarations related to emissions of GHG. From 2024, these three questionnaires on climate change, water security, and forests were integrated into a single CDP 2024 questionnaire , creating a structure for identifying the mutual relationships between environmental issues and comprehensively understanding the state of initiatives by companies.

With the CDP’s 2024 survey, survey activities were conducted on behalf of over 700 institutional investors with net invested assets totaling 142 trillion USD. More than 24,800 companies disclose environmental data on their initiatives for climate change programs via the CDP.

In 2024, a total of 3,300 Japanese companies including all Tokyo Stock Exchange Prime Market listed companies were chosen as target companies for disclosure requests.

Upon responding to the CDP questionnaire for FY2024, we received an A- rating for climate change and a B rating for water security. We also received requests for responses in FY2025 regarding climate change and water security as well, to which we have responded.

The TCFD initiative, for which we expressed our agreement in February 2021, is introduced in [Information Disclosure Based on the TCFD Recommendations (Response to Climate Change)].

Following the announcement of our support for the GX League*2 Basic Concept published by the

Ministry of

Economy, Trade and Industry in FY2022, we have set targets for our domestic Group and are reporting GHG

emissions performance values for FY2023 as a participating company in the GX League which we joined in May

2023.

(https://dashboard.gx-league.go.jp/company/9010701005073/)

Going forward, our Group will continue to proactively disclose information on the risks and opportunities associated with climate change and fulfill its responsibility to account to all stakeholders.

We will move forward with environmental information disclosure as we contribute to the response to climate change through reduction of environmental impact, resource and energy conservation, management of chemical substances, and development of products that contribute to the environment.

- *1 CDP: Formerly “The Carbon Disclosure Project.” “CDP” is now the official name.

- *2 GX League: Established as a forum for cooperation between a group of companies and the government, universities, and academic institutions in order to meet greenhouse gas reduction targets and increase industrial competitiveness by using Japan’s goal of carbon neutrality by 2050 as an opportunity for economic growth.

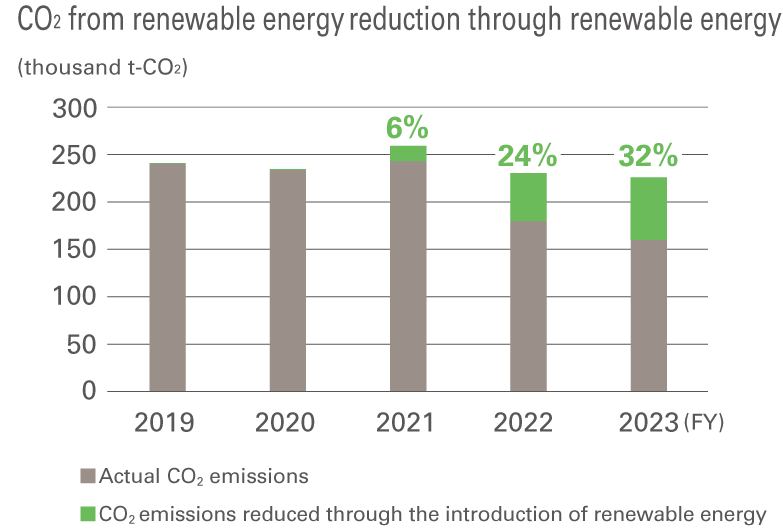

Reducing energy use and GHG emissions

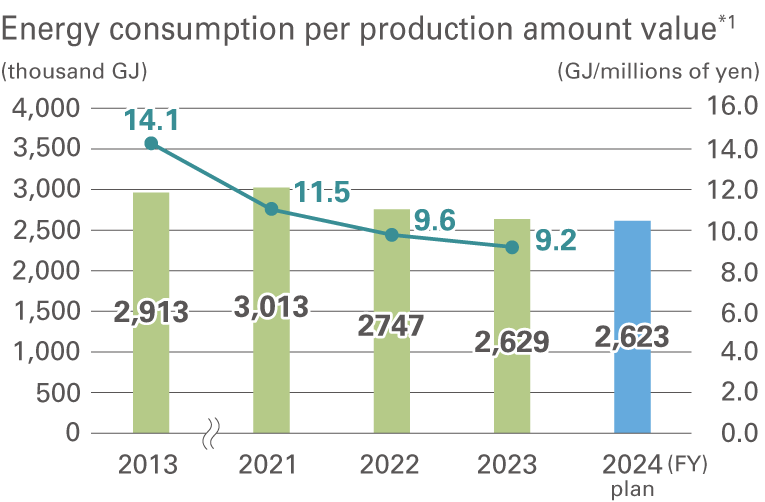

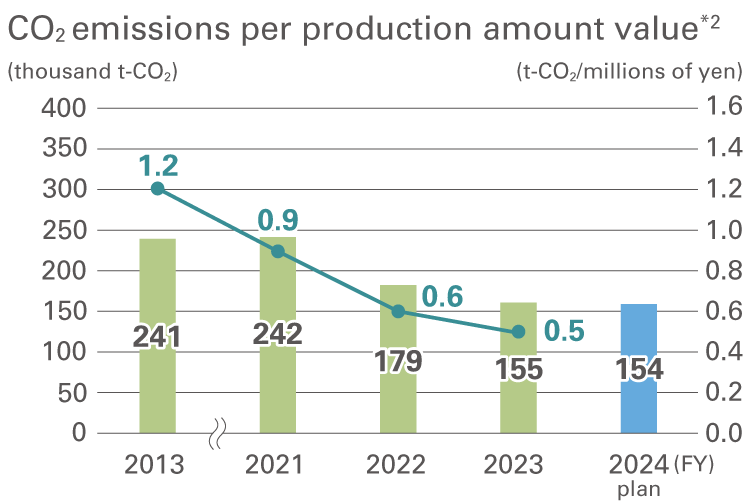

Our Group is promoting the introduction of renewable energy. All of our domestic business sites have already switched their purchased electricity to electricity derived from renewable energy sources at all manufacturing and research sites, and our overseas business sites are also pursuing the planned introduction of renewable energy. We are also actively promoting installation of solar power generation, with both energy consumption per production amount value and GHG emissions per production amount value showing reduction trends during FY2024.

● Energy Consumption per Production Amount Value*1

● GHG Emissions per Production Amount Value*2

-

*1, *2 Energy consumption and GHG emissions per production amount value are determined using the

following equation for sales per production amount value. The scope of aggregation covers Sumitomo

Bakelite Co., Ltd. and its consolidated subsidiaries.

- • Energy consumption per production amount value = Energy consumption [thousand GJ] / Net sales [million yen]

- • GHG emissions per unit production value = GHG emissions (Scope 1 + Scope 2) / Net sales [million yen]

Initiatives for reducing emissions during the production and sales stages

Our Group was early to pursue switching from petroleum-based fuels to natural gas at domestic and overseas business sites.

Natural gas emits less SOx and NOx and around 30% less GHGs compared to petroleum-based fuels. Although heavy oil is still used at some business sites in Japan, progress is being made with plans to switch these to city gas.

Currently, natural gas and city gas account for around 88% of the fuel used by our entire Group, but we are aiming to achieve 90% or more by 2027 by moving ahead with conversion at our domestic subsidiaries.

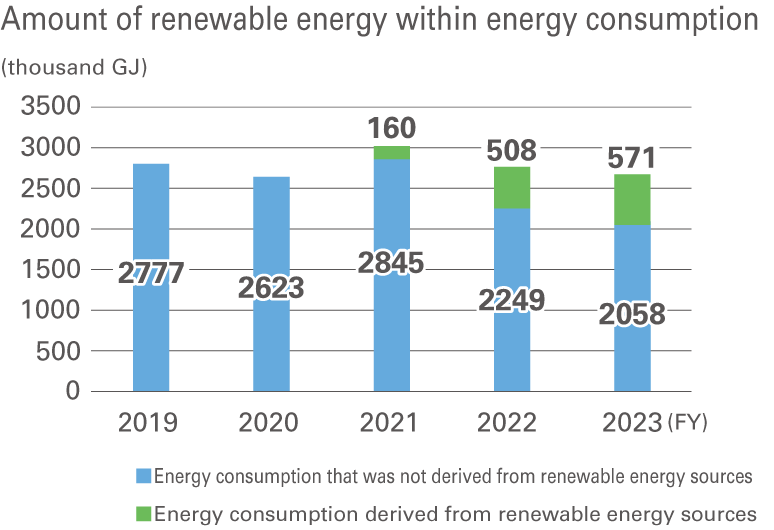

At the same time, we are also pursuing GHG reduction through the introduction of renewable energy, and have continued to promote switching to electricity from renewable energy sources and expansion of solar power generation.

As a result, the reduction in our global GHG emissions from the use of renewable energy sources accounts for 42% of the total in FY2024.

● Trend of Renewable Energy Consumption among Total Energy

- Note: The scope of aggregation covers Sumitomo Bakelite Co., Ltd. and its consolidated subsidiaries.

● Trend of CO2 Reduction through Renewable Energy

- Note: The scope of aggregation covers Sumitomo Bakelite Co., Ltd. and its consolidated subsidiaries.

Initiatives for reducing Scope 3 emissions

Our Group recognizes that not only reducing the GHG emissions from our own activities, but also reducing emissions through the entire value chain is an important problem.

Because of this, we have announced a Scope 3 reduction target of “25% reduction compared to FY2021 by 2030,” and are promoting initiatives to achieve this target.

Emissions at the raw material procurement stage (Category 1) accounted for a large portion of Scope 3 emissions, and reducing these is a major issue going forward.

We continue to strengthen coordination with suppliers and are accelerating our efforts towards Scope 3 reduction.

● CO2 Emissions (by Scope 3 category): Group of Sumitomo Bakelite Co., Ltd.

| Category | Emissions (thousand t-CO2/year) | ||||

|---|---|---|---|---|---|

| FY2021 | FY2022 | FY2023 | FY2024 | ||

| 1. Purchased goods and services | 939 | 856 | 718 | 761 | |

| 2. Capital goods | 39 | 50 | 65 | 49 | |

| 3. Fuel- and energy-related activities not included in Scope 1 & 2 | 45 | 40 | 39 | 40 | |

| 4. Upstream transportation and distribution | 93 | 81 | 70 | 72 | |

| 5. Waste generated in operations | 13 | 10 | 6 | 6 | |

| 6. Business travel | 2 | 2 | 2 | 2 | |

| 7. Employee commuting | 5 | 5 | 5 | 5 | |

| 8. Upstream leased assets*1 | - | - | - | - | |

| 9. Downstream transportation and distribution*2 | - | - | - | - | |

| 10. Processing of sold products*3 | - | - | - | - | |

| 11. Use of sold products*4 | - | - | - | - | |

| 12. Disposal of sold products | 49 | 43 | 40 | 43 | |

| 13. Downstream leased assets*1 | - | - | - | - | |

| 14. Franchises*1 | - | - | - | - | |

| 15. Investments | 9 | 10 | 11 | 9 | |

|

Scope 3 (indirect emissions other than Scope 1 and Scope 2) |

1,194 | 1,097 | 956 | 987 | |

| Scope 1 (direct emissions such as due to fuel consumption) | 97 | 86 | 81 | 79 | |

| Scope 2 (indirect emissions due to energy use such as electricity and heat) | 149 | 96 | 75 | 56 |

- *1 Not applicable due to business characteristics.

- *2 Transportation and delivery beyond the point where the Group acts as the shipper is excluded from the scope, as detailed information cannot be obtained and calculation is difficult.

- *3 The Group’s main products are materials with diverse applications and processing methods, making detailed determination difficult, and therefore, these products are excluded in accordance with the guidelines for the chemical sector established by the WBCSD.

- *4 The products sold by the Group generate no GHG emissions at the time of use, and therefore are excluded.

Calculation method: We calculated the amount of emissions based on the Emissions Intensity Database for Calculating Greenhouse Gas Emissions of Organizations through the Supply Chain Ver. 3.5 and emission coefficients from the Sustainable Management Promotion Organization IDEA Ver. 3.3.

Response to the “Fluorocarbon Emissions Control Act”

Based on the “Fluorocarbon Emissions Control Act” that was enacted in April 2015 and further enhanced in April 2020, our Company ensures comprehensive awareness of laws and regulations at each business site, and conducts regular quick inspections of commercial air conditioners and freezer systems in our possession.

Furthermore, statutory regular inspections are carried out without fail on equipment with a rated power of 7.5 kW or more, and an appropriate management system is maintained. Given that there are a large number of air conditioners, particularly for office use, we are also working on strengthening the management system through annual internal audits to prevent omissions and missing inspections during upgrades.

We are also actively promoting the switch to refrigerants with zero ozone depletion potential and low global warming potential with the aims of preserving the ozone layer and curbing global warming. Existing facilities are regularly inspected on a yearly basis for the amount of leakage in accordance with the “Fluorocarbon Emissions Control Act”, to check that there are no leaks in amounts that are required to be reported.

These initiatives by our Company were assessed and were awarded the highest rank of “A”, the same as the previous year, in the “Fourth JRECO CFC Control Measure Rating by the Japan Refrigerants and Environment Conservation Organization”, which aims to enlighten and promote compliance with the “Fluorocarbon Emissions Control Act”, together with the Ministry of Economy, Trade and Industry and the Ministry of the Environment.

Moving forward, our Company is continuing with initiatives to contribute to preservation of the environment.