Policy and Basic Approach

Environmental Policy

Our Group has established the Environmental Policy as a policy related to environmental issues pertaining to our Group (including resource circulation, waste reduction and pollution prevention). Our Group's Environmental Policy is described on the following page.

Systems (Governance)

The systems for supervision and management of environmental issues pertaining to our Group (including resource circulation, waste reduction, and pollution prevention) are described on the following page.

Risk Management

The identification, assessment, and management of risks and opportunities related to environmental issues pertaining to our Group (including resource circulation, waste reduction, and pollution prevention) are carried out in accordance with the risk management structure and risk management processes described on the following page.

Metrics and Targets

Promoting Reduction of Material Loss

Our Group is actively working to reduce all material losses including not only

waste

materials but also valuable materials in order for efficient utilization of limited

resources.

Currently, we are continually promoting reducing our environmental impact and efficiently

utilizing resources through our own analysis of manufacturing processes and activities to

reduce material losses using the Material Flow Cost Accounting (MFCA)*1 method.

Moving

forward, we are aiming to increase productivity through business expansion while reducing

material losses by comprehensively identifying losses and promoting reduction measures.

- *1: See the Glossary.

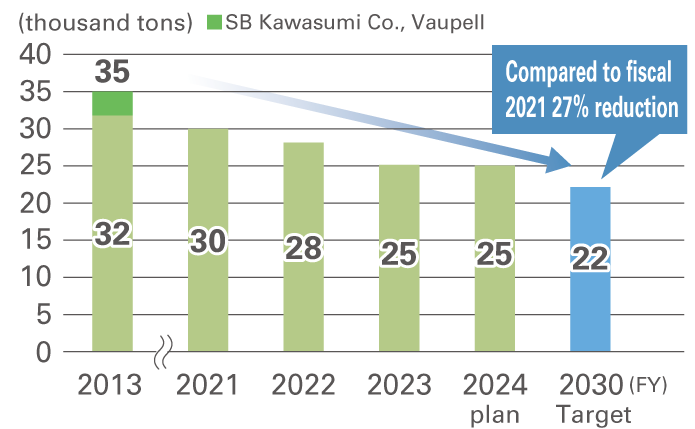

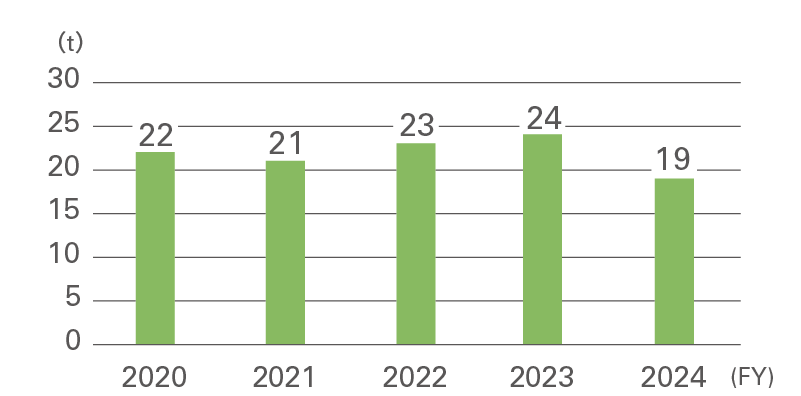

● Amount of Material Losses: Group of Sumitomo Bakelite Co., Ltd.

|

|

Reduction of chemical substance emissions

Our Group has set targets for reduction not only of the chemical substances

designated by the Act on the Pollutant Release and Transfer Registers (PRTR Act) but also

chemical substances designated separately by the Japan Chemical Industry Association.

In some

of our business sites in Japan, we are contributing to reducing emissions of chemical substances

as a result of efforts to switch to manufacturing methods that do not use organic

solvents.

At our overseas business sites, although it is unavoidable to use chemical

substances in certain processes for reasons such as maintaining quality, we are continuing to

investigate and implement measures for reducing emissions from a medium- to long-term

perspective.

- *1: See the Glossary.

● Chemical Substances Emissions: Group of Sumitomo Bakelite Co., Ltd.

|

|

Key Initiatives

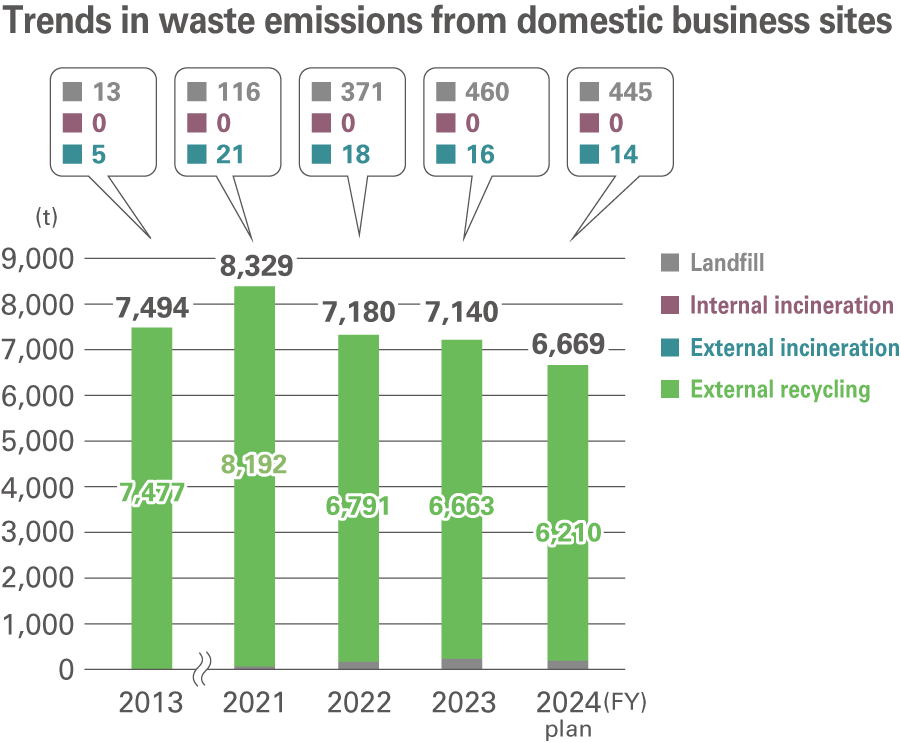

Waste management

Our Group adheres to environmental laws and regulations, and conducts business activities aiming to reduce our impact on the global environment. For waste materials at Japanese business sites, we have established rules for on-site verification of waste disposal contractors in accordance with the Waste Management and Public Cleansing Law , and we continue to quantify and manage the amount of waste generated based on manifests. Based on the above, we promote minimization of waste generation and recycling, and activities to reduce material loss, including valuable materials.

Furthermore, for polychlorinated biphenyl (PCB) waste, we are continuing to act in accordance with the PCB Special Measures Law , and are making progress with our plan to complete the disposal by the legally mandated deadlines for both high-concentration PCBs and low-concentration PCBs.

Our Group is placing importance on reducing environmental impact throughout all of society through our products and services, and are actively working on “developing products that give consideration to reducing GHG emissions throughout their entire life cycle.” We are also contributing not only to reducing GHG but also to reducing waste materials throughout the entire supply chain through the development of products that offer lighter weight (smaller volume), longer service life, recyclable design, and mono-material design (switching to a single material).

In FY2024, our emissions of waste materials increased compared to the previous fiscal year due to unexpected factors in the production process. To address this issue, we are continuing to promote measures to reduce waste materials and employ initiatives for achieving our long-term goal.

● Trends in Waste Generation (By Disposal Type): Business Sites in Japan

-

* Figures include the total of externally recycled waste, landfill waste,

internally incinerated waste, and externally incinerated waste.

Since FY2012, internal incineration has not been carried out at any business site in Japan.

Initiatives for resource circulation

Recycling

Our Group promotes recycling as a means to make efficient use of resources. This recycling includes the recovery and recycling of phenol from waste liquid produced by phenolic resin reactions during the product production process, fine grinding of offcuts from phenolic laminated sheets and decorative melamine resin laminates for use as a filler in phenolic molding compounds, reuse of molded parts by-products (sprues and runners) as raw material for molding materials, as well as reuse of excess sludge from activated sludge effluent treatment equipment as compost (organic fertilizer).

Renewable raw materials

Our Group has been actively using inedible plant-derived raw materials (cashew nutshell oil, rosin (pine resin), wood flour, etc.) as renewable raw materials, primarily for phenolic resins and molding compounds.

We have added to our product lineup packaging films for food and pharmaceutical products made from renewable biomass materials, and have also added eco-friendly phenolic molding compounds using plant-derived lignin. The ratio of renewable raw materials to total raw materials used by our Group is about 2.8% at the current point in time.

Moving forward, we are aiming to further improve the proportion of renewable materials used while making the most out of the properties of those materials.

Marine plastics

When it comes to the problem of marine plastics, we are moving ahead with activities to contribute to reducing plastic marine waste via a number of initiatives based on the Japanese government’s Plastic Resource Recycling Strategy. These initiatives include managing the raw materials used and the plastic products we manufacture, promoting the recycling of said products, and developing new products.

We are currently taking part in the Japan Clean Ocean Material Alliance (CLOMA), which was established by a broad range of business operators related to supply chains for plastic products, including those in the chemical industry and distribution/retail industries, with the goal of forming cross-industry partnerships. Through this, we are working to address a variety of challenges by aiming to curb plastic waste across our supply chain as a whole and promoting resource circulation via 3R + Renewable products activities for plastic products.

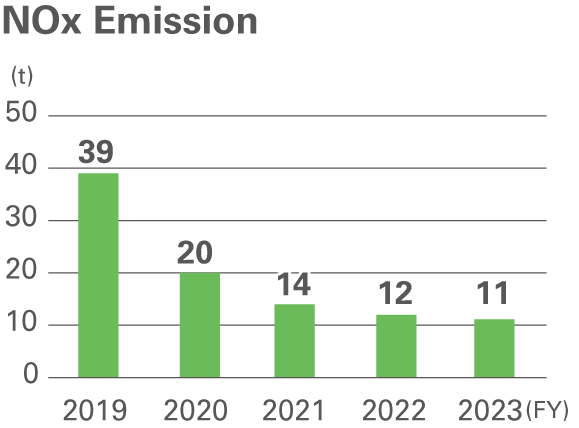

Emissions into the atmosphere

We have been promoting the conversion of boiler fuel from heavy oil to city gas

over the long term, and have greatly reduced SOx emissions.

Furthermore, we

are continuing to implement measures to optimize and stabilize the operating

conditions of our boilers, and are working steadily to reduce emissions of NOx,

soot, and dust.

We are aiming to further reduce our environmental impact by

maintaining the current low level of emissions and making progress with our plan

to convert our remaining heavy oil to town gas.

● Soot and Dust Emissions (Business Sites in Japan)

- * The scope of aggregation covers business sites of Sumitomo Bakelite Co., Ltd. and its consolidated subsidiaries where measurement is required by laws and regulations.

● NOx Emissions (Business Sites in Japan)

- * The scope of aggregation covers business sites of Sumitomo Bakelite Co., Ltd. and its consolidated subsidiaries where measurement is required by laws and regulations.

● SOx Emissions (Business Sites in Japan)

- * The scope of aggregation covers business sites of Sumitomo Bakelite Co., Ltd. and its consolidated subsidiaries where measurement is required by laws and regulations.

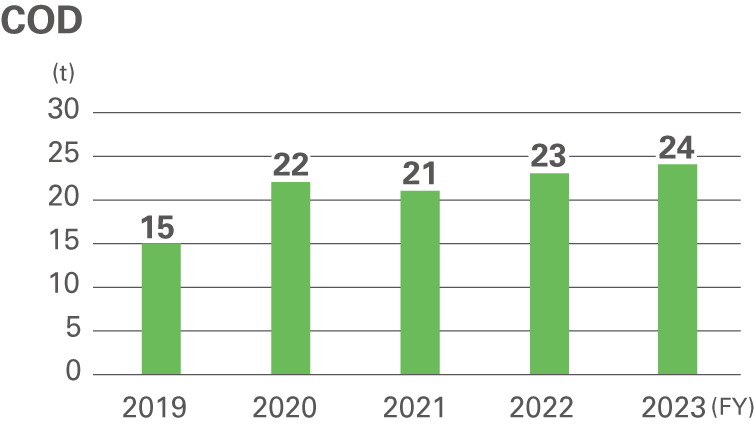

Emissions into the hydrosphere

Effluent discharged from plants includes pollutants, which are categorized into industrial and household sewage. Treatment facilities, such as high-concentration phenol recovery equipment and activated sludge treatment equipment, and surveillance systems for constant monitoring are in place to ensure strict compliance with environmental standards and laws and regulations at the national and local government levels.

Additionally, risk assessments are conducted on leakages into rainwater that also includes cooling water to prevent sudden and unexpected increases in environmental impacts.

COD load, a typical indicator of water quality, has remained at a low level when viewed over the long term, and going forward we are continuing with initiatives to maintain and improve on this state.

● COD Load

- * The scope of aggregation covers business sites of Sumitomo Bakelite Co., Ltd. and its consolidated subsidiaries where measurement is required by laws and regulations.

Response to soil/underground water pollution

Our Group carries out risk assessments relating to leakage of chemical substances at all of our business sites, and we promote both the development and implementation of preventive frameworks. At the same time, when contamination caused by past leakage accidents is confirmed, we actively undertake voluntary surveys and institute countermeasures in order to prevent the environmental impact and health damage from spreading.

We did not suffer any severe leakage accidents in FY2024.