April 14, 2025

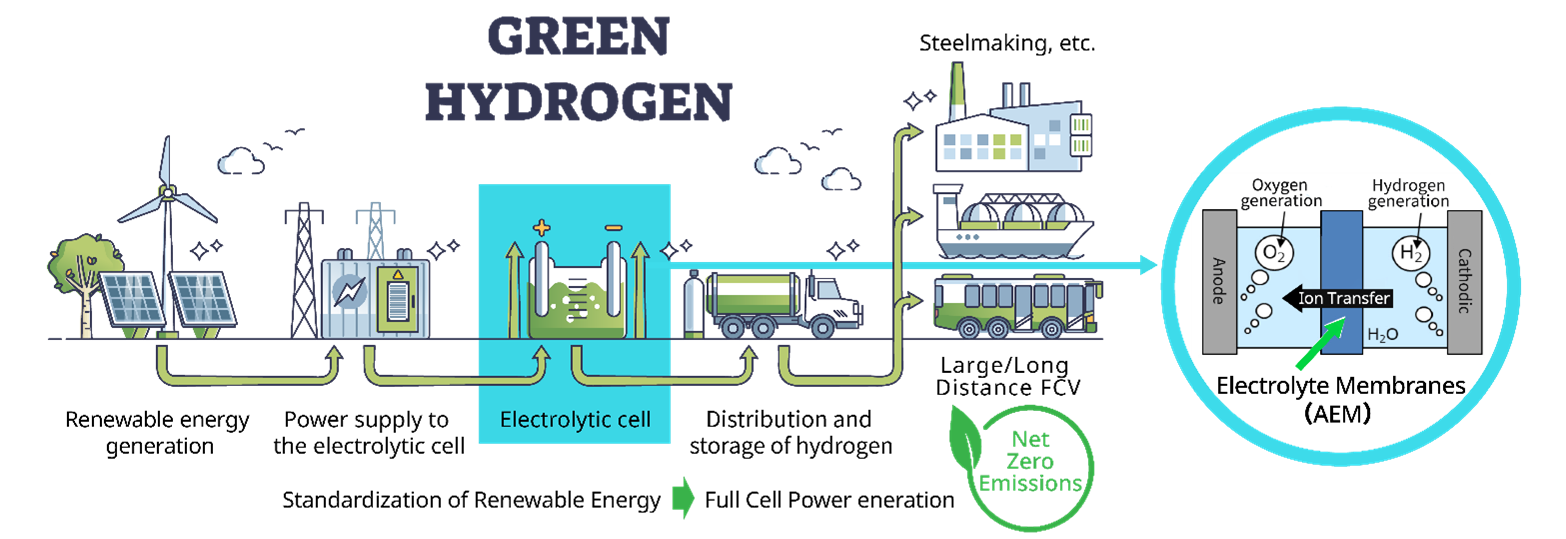

Tokyo, Japan - April 14, 2025, Sumitomo Bakelite Co., Ltd. (TOKYO: 4203 HQ: Shinagawa-ku, Tokyo, President and Representative Director: Kazuhiko Fujiwara) has been conducting research and development on ion exchange membranes for water electrolysis with the aim of realizing the social implementation of green hydrogen energy utilizing renewable energy. A PFAS-free ion exchange membrane has been successfully prototyped and is being evaluated by water electrolysis equipment manufacturers.

Sumitomo Bakelite Co., Ltd., announces the launch of “the Project Team to Prepare for Mass Production of Functional Membranes for Hydrogen Production” in order to establish a mass production system for anion exchange membranes (AEM) *1 for hydrogen production equipment and to focus on developing new customers.

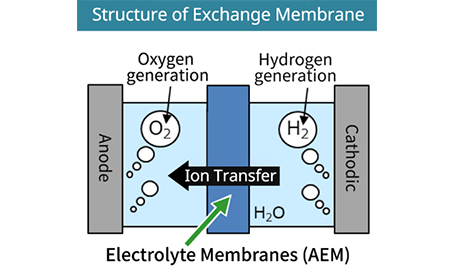

*1 An anion exchange membrane (AEM) for hydrogen production equipment is a type of membrane mainly used in water electrolysis equipment and fuel cells. It is a material that selectively permeates anions (negatively charged ions). This membrane operates in an alkaline environment and plays an important role in efficiently progressing electrochemical reactions.

Background

In recent years, as the movement toward carbon neutrality is accelerating in countries around the world, expectations for the utilization of hydrogen energy are rapidly increasing. However, to realize the social implementation of hydrogen energy, several issues and technological developments to solve them are required. Currently, the majority of hydrogen is “gray hydrogen” (hydrogen derived from fossil fuels) for industrial applications (such as chemical processes and petroleum refining). However, since a large amount of carbon dioxide (CO2) is emitted in the production process, a high environmental impact is a problem. Therefore, to realize carbon neutrality, a shift from gray hydrogen to low-carbon hydrogen (such as green hydrogen) is required, and governments and companies in various countries are actively investing. (The features of each water electrolysis)*2

Issues in Hydrogen Production Equipment

In hydrogen production equipment, there are various methods for electrolysis of water, which is used as energy, but alkali type and proton exchange membrane (PEM) type have been in the forefront. Water electrolysis equipment using anion exchange membrane (AEM), which has high generation efficiency at low cost, is attracting attention as a new technology, and our company has newly established a project team for mass production of this AEM.

About Anion Exchange Membrane (AEM) for Hydrogen Production Equipment

|

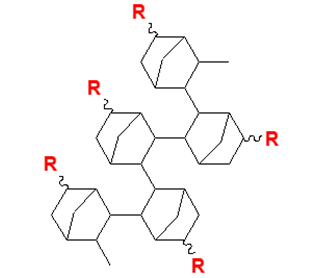

The anion exchange membrane (AEM) for hydrogen production equipment, which is being mass-produced, has high ionic conductivity, stability, and durability, and is PFAS-free. It uses a proprietary material, polynorbornene (PNB), developed by our group’s Promerus, LLC (Ohio, USA), and is an epoch-making material that Sumitomo Bakelite Co., Ltd. will mass-produce in the future by making use of the process technology it has cultivated for many years. |

|

Polynorbornene [NB material (proprietary material)] with a High Degree of Design Freedom

This product uses polynorbornene as a membrane material with a high degree of design freedom and is a PFAS-free material with high ionic conductivity.

Features of Polynorbornene

- A high degree of design freedom that enables the inclusion of mechanical properties, thermal properties, adhesiveness, and other functions depending on the application

- High ionic conductivity is realized by introducing various functional groups

Designing materials suitable for AEM electrolyte membranes by adding functions to PNB materials

|

Representative Structure of Polynorbornene (PNB)

|

High degree of design freedom to add various functions |

Superiority of Our Company Technology

Note: According to our company, there is no fluorine-free type of AEM at present. |

|

Plans After the Launch of the Project Team

At present, we have obtained good results in the laboratory evaluation by our customers, and the evaluation is progressing smoothly.

We expect to establish production conditions by FY 2027 and mass production by FY 2030. In the future, we aim to achieve 100 billion yen/year in sales.

*2 Comparison of Water electrolysis apparatus

- Alkaline (AWE) type

AWE type water electrolytes are a mature technology with a long history in commercial applications. It uses an alkaline solution (usually potassium hydroxide or sodium hydroxide) as the electrolyte and is highly durable and reliable.

The advantage is that inexpensive electrode materials can be used, but the equipment tends to be relatively large and may not be suitable for home use or small-scale distributed hydrogen production equipment. - Proton exchange membrane (PEM) type

The PEM type, which uses a proton exchange membrane as the electrolyte, has become popular in recent years. It can be designed to be highly efficient and compact and is suitable for integration with renewable energy. It can produce hydrogen with high efficiency and purity, but the operation environment is acidic, so precious metals (such as platinum and iridium) must be used as the electrodes, and the cost is high. - Anion exchange membrane (AEM) type

The AEM type is a new method that operates in an alkaline environment and uses an anion exchange membrane as the electrolyte. It is attracting attention because of its low cost and the possibility of not requiring precious metals. However, the technology is still developing and its use on a commercial scale is currently limited. It does not use precious metals, can use inexpensive electrode materials, and has characteristics that combine the advantages of alkaline type and PEM type. Research and development is progressing, and cost reduction is expected in the future.

| Alkaline (AWE) type | Proton exchange membrane (PEM) type | Anion exchange membrane (AEM) type | |

|---|---|---|---|

| Catalyst cost | 〇 | △ (Pt, Ir) | 〇 (Ni, Fe, Co) |

| Efficiency | △ | 〇 | 〇 |

| Hydrogen pressure | △ | 〇 | 〇 |

| Market performance | Yes | Some | Some |

| Application | Large scale (plant, etc.) | Small to medium | Small to large |

Note: Comparison based on our company survey

[Contact information]

Hydrogen Membrane Mass Production Preparation Project Team,

Sumitomo Bakelite Co., Ltd.