Policy and Basic Approach

Our Group believes that ensuring the occupational health and safety of employees is the cornerstone of our business activities. We established the SB Machine Safety Guidelines and SB Safety Action Guidelines based on the Safety Philosophy of “Safety is the first priority of all,” and ensuring that everyone, including our employees and on-site partner companies , focuses on achieving a workplace free from injuries, accidents and disasters by eliminating various hazards and harmful factors from the workplace.

Occupational Health and Safety Policy

- Based on our Safety Philosophy, “Safety is the first priority of all”, we are committed to achieving zero accidents and injuries at our workplaces and maintaining safe and stable operations.

- We ensure the safety of our stakeholders including employees and local communities by continuously improving occupational health and safety, accident prevention, and other safety-related issues based on risks.

Application: All Group business sites and subsidiaries in Japan and overseas

Systems (Governance)

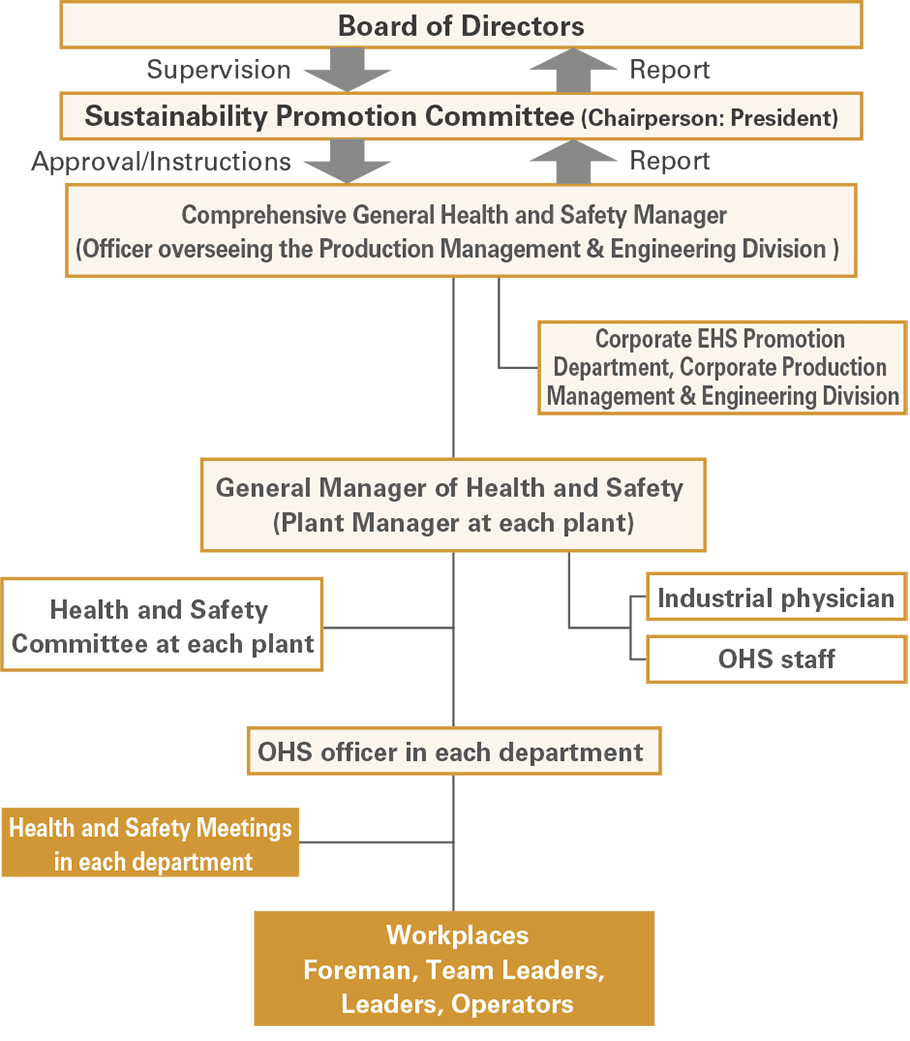

Occupational Health and Safety Management System

Our Group has established the Sustainability Promotion Committee chaired by the President. This committee determines health and safety policies along with important measures for preventing accidents and disasters, and based on these, rolls out health and safety activities across the entire Group.

In addition, we enacted our uniform company-wide Safety Philosophy: Safety Is the First Priority of All and our three SB Safety Action Guidelines in October 2019 and SB Machine Safety Guidelines in December 2023 to promote the complete elimination of fatal accidents and serious disasters.

The Officer overseeing the Production Management & Engineering Division serves as Comprehensive General Health and Safety Manager for the whole company. Each business site implements initiatives tailored to the needs of individual workplaces within a company-wide framework, under the responsibility of the Plant Manager at each plant. At its monthly meetings, the Health and Safety Committee reviews health and safety management activities, ensures thorough compliance with relevant laws and ordinances, and considers capital investments to realize risk reduction, among other actions.

Certification of Occupational Health and Safety Management Systems

We are in the process of obtaining ISO 45001 certification for our Group’s occupational health and safety management systems. Please see the following link for details.

Proportion of ISO 45001 certified sites

64%: Based on number of sites

(As of March 31, 2025, proportion of certified manufacturing sites)

Risk Management

The identification, assessment, and management of risks and opportunities related to occupational health and safety/accident prevention pertaining to our Group are carried out in accordance with the risk management structure and risk management process described on the following link.

Metrics and Targets

We have selected health and safety as one of our Group’s material issues, and set the number of serious occupational accidents, the number of accidents caused by fire and/or explosion resulting in operational stoppage, and the number of off-site spill incidents as KPIs, which we track and manage.

Other main indicators relating to occupational accidents are shown below.

Trends in the Frequency Rate and Severity Rate of Occupational Accidents

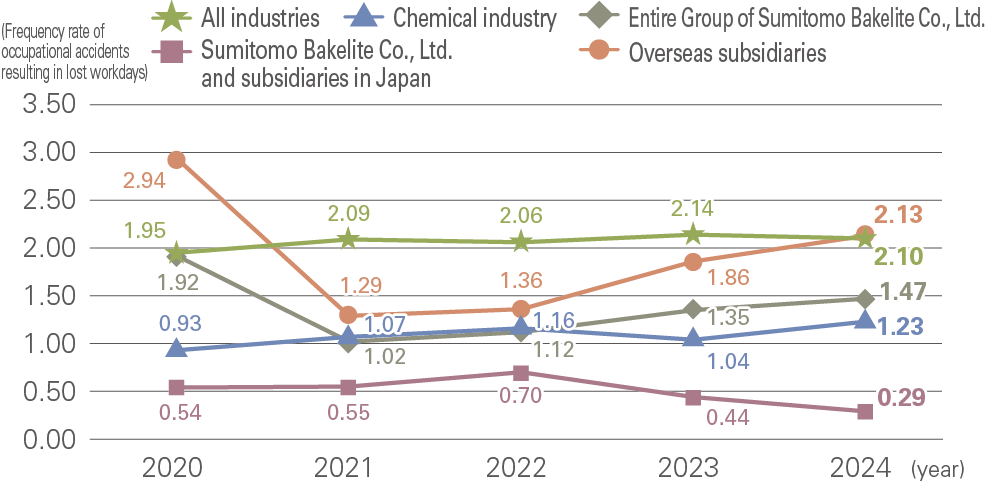

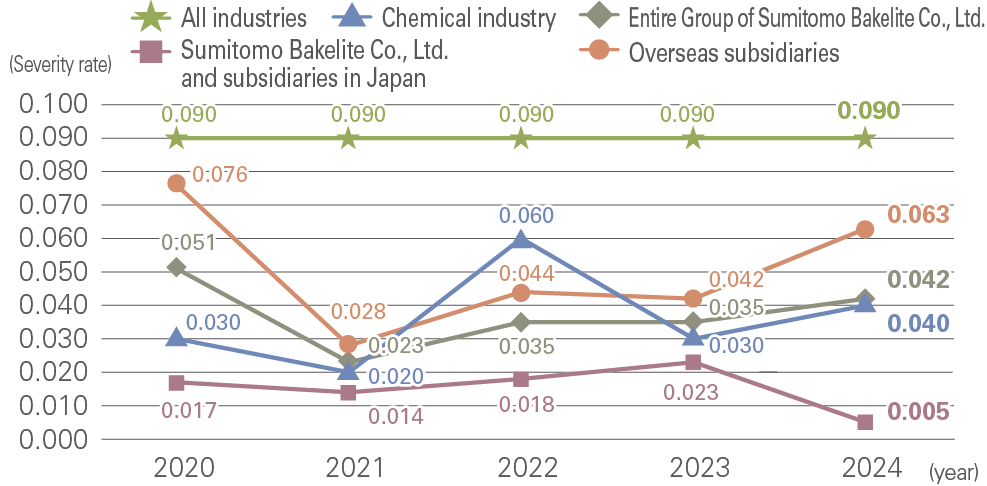

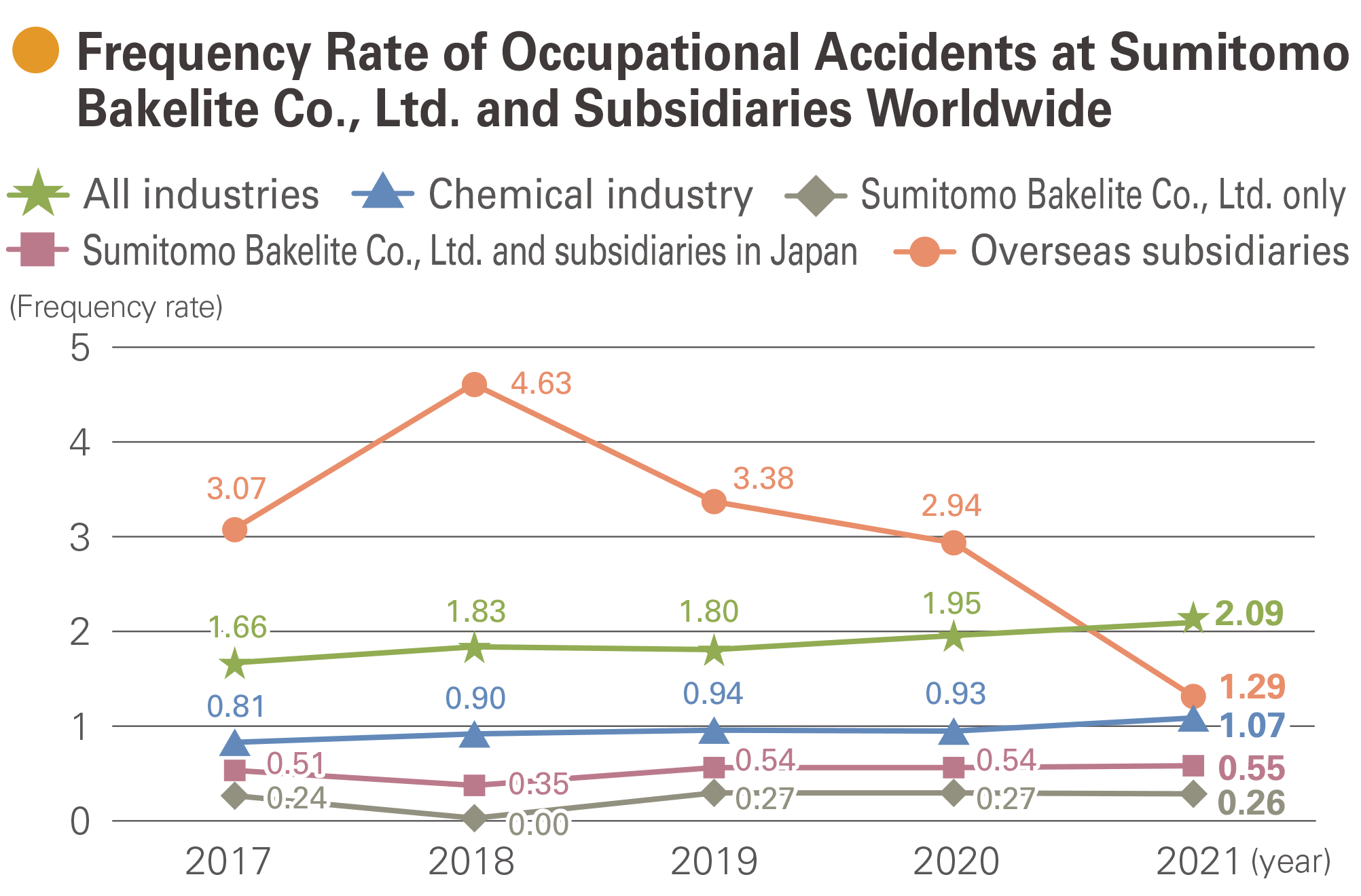

The graphs below show the changes in frequency and severity rates of occupational accidents involving

employees of our Group (including subsidiaries in Japan and overseas).

In 2024, the frequency and severity rates were both worse than the previous year, due to an increase in

the number of occupational accidents resulting in lost workdays at overseas subsidiaries.

●Frequency Rate of Occupational Accidents at Our Group (Including Subsidiaries in Japan and Overseas)*1

- *1 Frequency Rate of Occupational Accidents = (Number of deaths and injuries resulting in lost workdays/total working hours) x 1,000,000

- Notes:

1. Assurance applies to frequency rates for the entire Group of Sumitomo Bakelite Co., Ltd., Sumitomo Bakelite Co., Ltd. plus subsidiaries in Japan, and overseas subsidiaries.

2. The period covered is from January to December of each year.

3. The graph on the left does not include figures for on-site partner companies. See the following link for details of the number of workers, total working hours, and number of injuries due to occupational accidents at on-site partner companies.

●Severity Rate of Occupational Accidents at Our Group (Including Subsidiaries in Japan and Overseas)*2

- *2 Severity Rate of Occupational Accidents = (Total lost workdays/total working hours) x 1,000

- Notes:

1. The period covered is from January to December of each year.

2. The graph on the left does not include figures for on-site partner companies. See the following link for details of the number of workers, total working hours, and number of injuries due to occupational accidents at on-site partner companies.

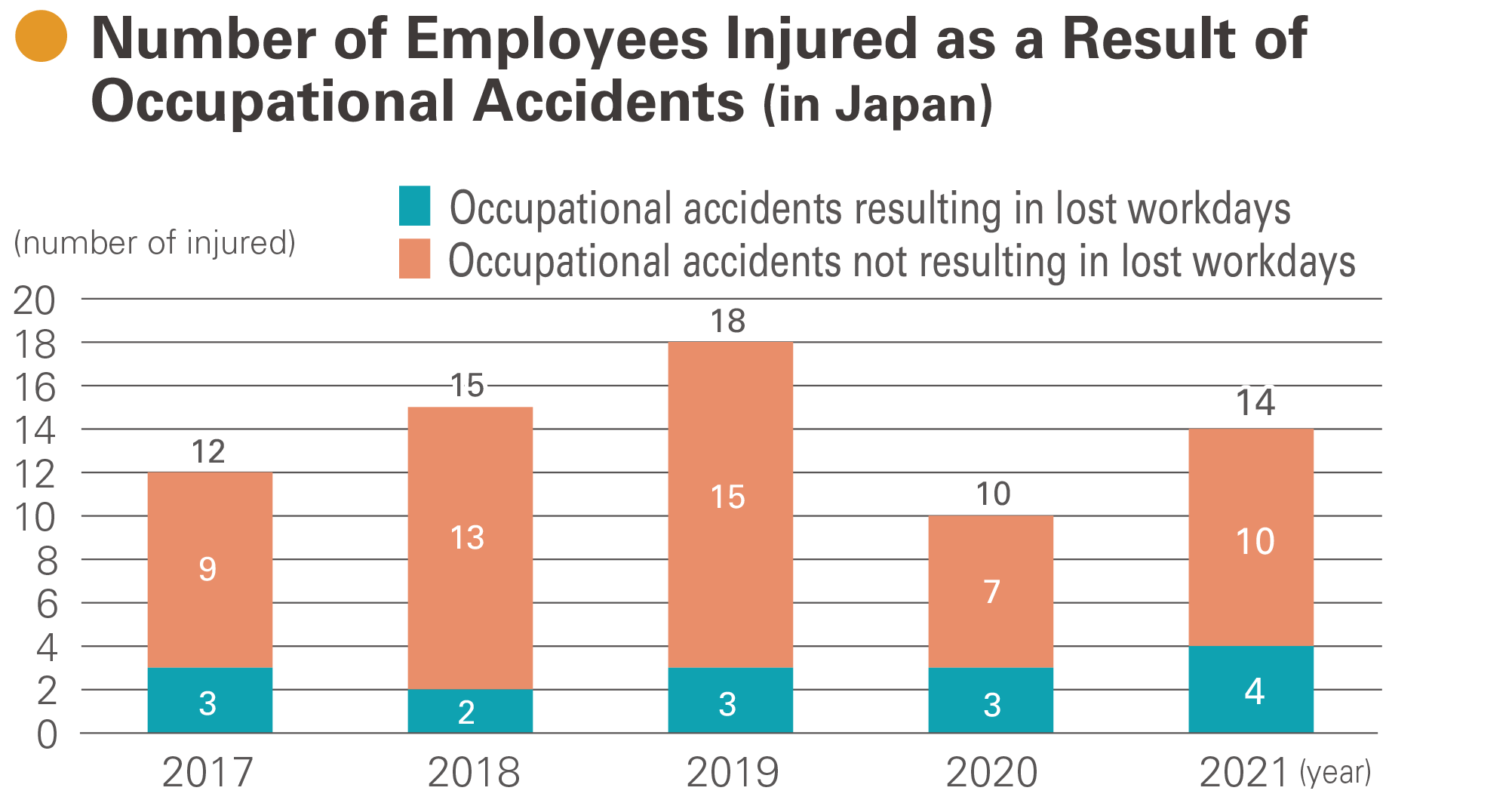

The Number of Employees Injured Due to Occupational Accidents

The graph below shows the number of employees injured due to occupational accidents at our Group

(including subsidiaries in Japan and overseas).

In 2024, there were two serious accidents corresponding to a level leading to subsequent disability at

overseas subsidiaries.

●The Number of Employees Injured Due to Occupational Accidents at

Our

Group

(Including Subsidiaries in Japan and Overseas)

- Notes:

1. The period covered is from January to December of each year. -

2. The graph on the left does not include figures for on-site partner companies.

See the following link for details of the number of workers, total working hours, and the number of injuries due to occupational accidents at on-site partner companies.

- 3. In 2024, there were no occupational accidents at on-site partner companies.

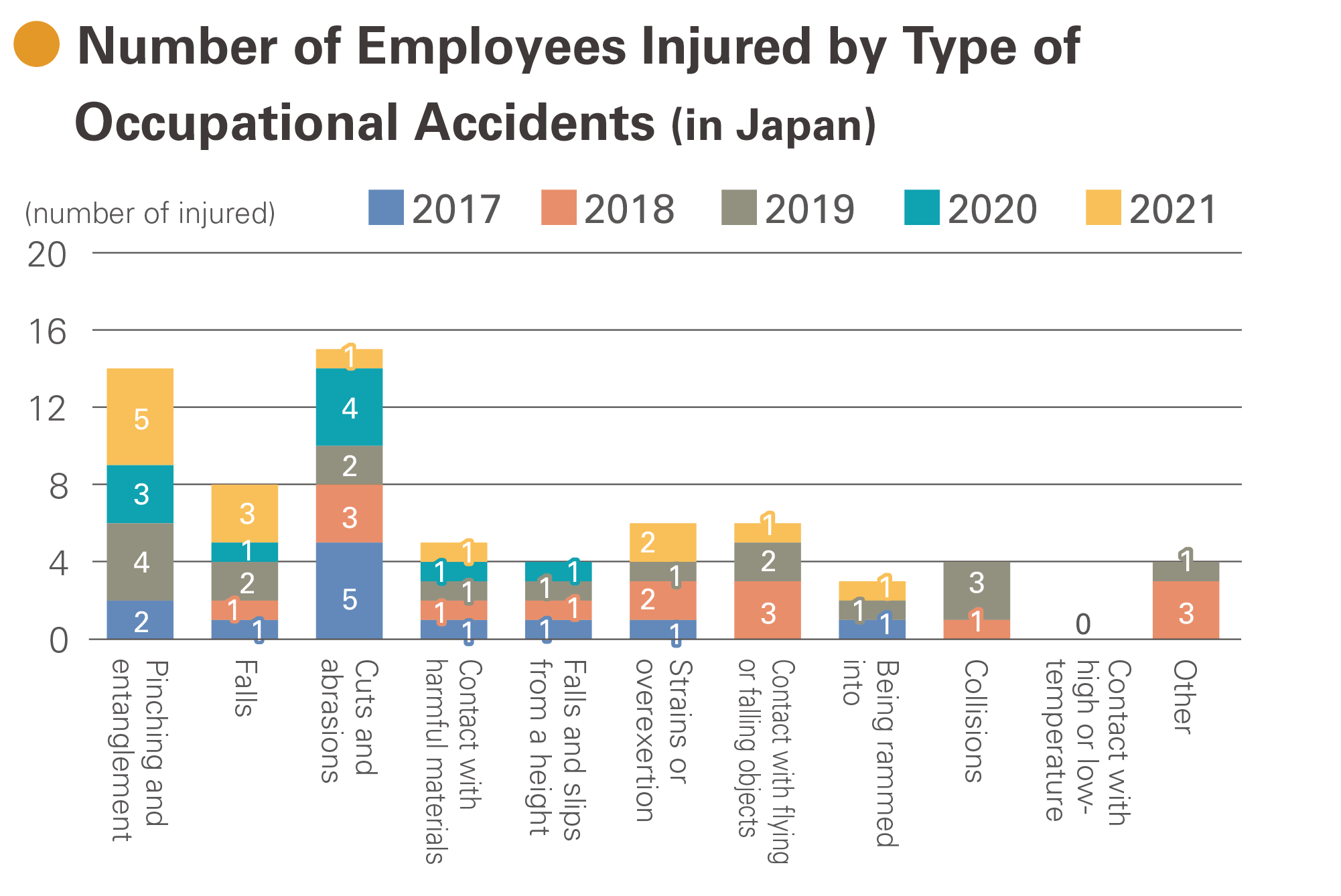

Occupational Accidents by Type

The graph below shows occupational accidents by type at our Group (including subsidiaries in Japan and

overseas).

“Pinching and entanglement” and “overexertion” made up over half of the occupational accidents in 2024.

Regarding “pinching and entanglement” accidents, which are directly linked to serious injuries, we are

continuing to promote SB Machine Safety Guidelines and SB Safety Action Guidelines. In the event of an

occupational accident, as well as risk assessment and corrective action to prevent recurrence based on

the results of investigations into the cause, efforts are made to prevent similar occupational accidents

from happening.

● Occupational Accidents by Type at Our Group (Including Subsidiaries in Japan and Overseas)

- Notes:

1. The period covered is from January to December of each year.

2. Data for SB-Kawasumi Laboratories, Inc. and its subsidiaries are added from 2021. Data for SB PAX Co., Ltd. are added from 2024.

See the following link for detailed information about occupational accidents, including frequency rate, severity rate, the number of employees injured due to occupational accidents, occupational accidents by type, etc.

Key Initiatives

Machinery and Equipment Risk Reduction Activities

All new machineries and equipments installed at domestic production plants and subsidiaries from 2008 and at overseas subsidiaries from 2009, have been designed in compliance with ISO 12100. We carry out risk assessments of existing machineries and equipments when changes occur, such as when modification is made to them or the work procedure is updated. To promote further safety, we established SB Machine Safety Guidelines to ensure the fundamental safety of machineries and equipments.

Risk Reduction Activities Relating to Chemical Substances

In 2012, we introduced chemical substance risk assessments at plants in Japan and subsidiaries worldwide. We reassess the risk assessment results when changes occur, such as information on the risks and hazards posed by chemical substances and work procedure revision. This is done with the aim of preventing adverse health effects to employees through exposure to chemical substances and to prevent explosion or fire incidents caused by chemical substances.

Health and Safety Education

To ensure safety at sites that handle machinery and chemical substances, we ensure safety through risk reduction activities to reduce the associated risks. In parallel with this, we are promoting Kiken Yochi (hazard prediction) training, point-and-call technique, and Hiyari-Hatto (near-miss) activities. Each business site has an Anzen Dojo (safety training center) where employees learn the fundamentals of safe conduct to improve safety awareness and risk identification skills.

Based on health and safety activities where the plant manager leads by example, education is provided for employees at each level, including specialized safety education for managers, education on laws and regulations for mid-level employees, and hands-on education for new employees regarding safety. In addition, we conduct on-site education (SB School “Safety” course) which is available to all employees at our Company and subsidiaries in Japan.

We also endeavor to share information in a timely manner by utilizing our online Safety Portal Site which is accessible to all Group employees. Safety education is implemented at all business sites, using resources such as VR devices and videos outlining our Safety Philosophy and SB Safety Action Guidelines.

See the following link for details of the number of people receiving safety education, etc.

[TOPIC] Award for Zero Accidents

The President awarded certificates to the following business sites in recognition of the length of time they have gone without an accident as a result of their safety efforts.

| Nava Nakorn Plant, Kawasumi Laboratories (Thailand) | ⇒ Achieved 3 million consecutive hours without an accident |

| Korat Plant, Kawasumi Laboratories (Thailand) | ⇒ Achieved 3 million consecutive hours without an accident |

| Amagasaki Business Site, Sumitomo Bakelite Co., Ltd. | ⇒ Achieved 1 million consecutive hours without an accident |

| S.B. Sheet Waterproof Systems Co., Ltd. (Nara Plant) | ⇒ Achieved 5 years without an accident |

| Notsu Factory, Oita Plant, SB-Kawasumi Laboratories, Inc. | ⇒ Achieved 1 million consecutive hours without an accident |

We will continue to implement initiatives in line with our Groupʼs Safety Philosophy and SB Safety Action Guidelines to achieve even more accident-free operations by promoting improvements through the concerted efforts of all employees.

Plant Security and Disaster Prevention

Accident prevention is the top priority of all our business sites. Our objective is to make business safer and more secure, and thus earn the confidence of the local community, ensure employee safety, and maintain stable supplies of products to customers. The Disaster Prevention Committee is convened and implements activities systematically with the aim of helping all business sites achieve zero accidents record. It also conducts emergency drills and puts in place accident prevention measures to minimize damage in the event that an accident does occur.

Disaster prevention training |

Lifesaving training (AED training) |

Disaster prevention training (fire evacuation practice) |

Fire defense training for mid- to high-rise buildings |

Safety assessment of confined spaces |

Emergency training (in case of chemical substance leaks) |

[TOPIC] First ASEAN Regional Safety Meeting

Four of our Group companies in the ASEAN region, SumiDurez Singapore Pte. Ltd., Sumitomo Bakelite Singapore Pte. Ltd., P.T. Indopherin Jaya, and SNC Industrial Laminates Sdn. Bhd. held the First ASEAN Regional Safety Meeting.

They conducted accident reviews for each site and site inspections.

As different products are handled at each site, it was stimulating to hear opinions from different perspectives. Going forward, we will deepen cooperation by visiting other sites, improving safety levels, and creating opportunities for interaction between local employees.