Product Introduction

|

We propose optimal processing methods based on our accumulated knowledge and technology. Please feel free to consult with us. |

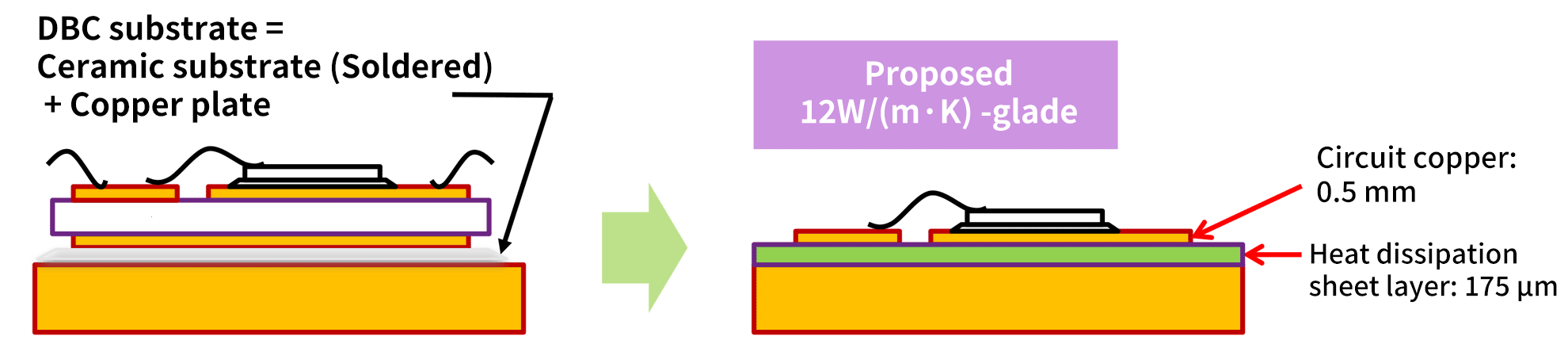

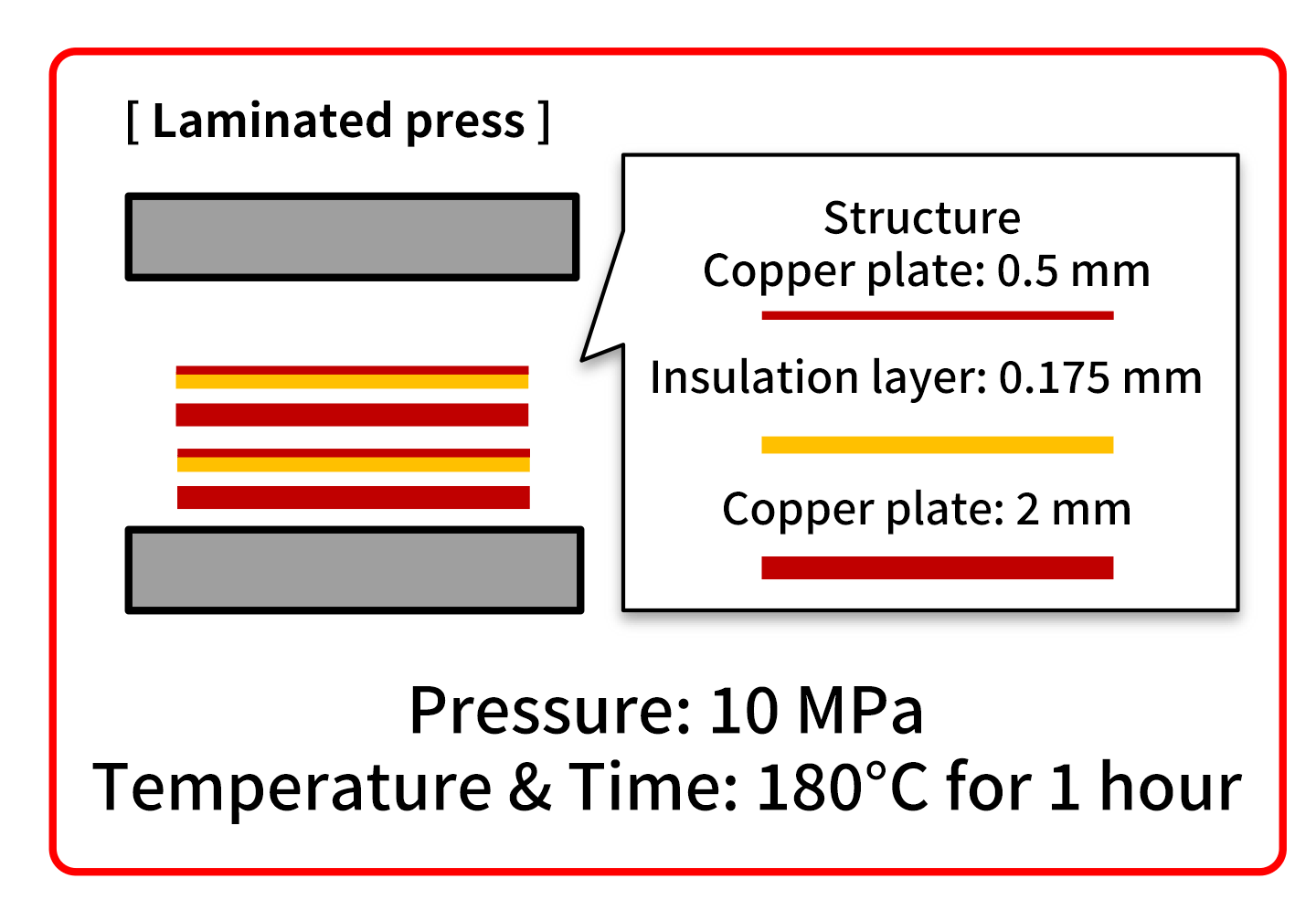

Compared to ceramic substrates, resin substrates exhibit less warpage, simplifying power module design,

chip mounting, and assembly.

This enables the realization of compact, lightweight power modules with high insulation reliability and

excellent heat dissipation.

General properties

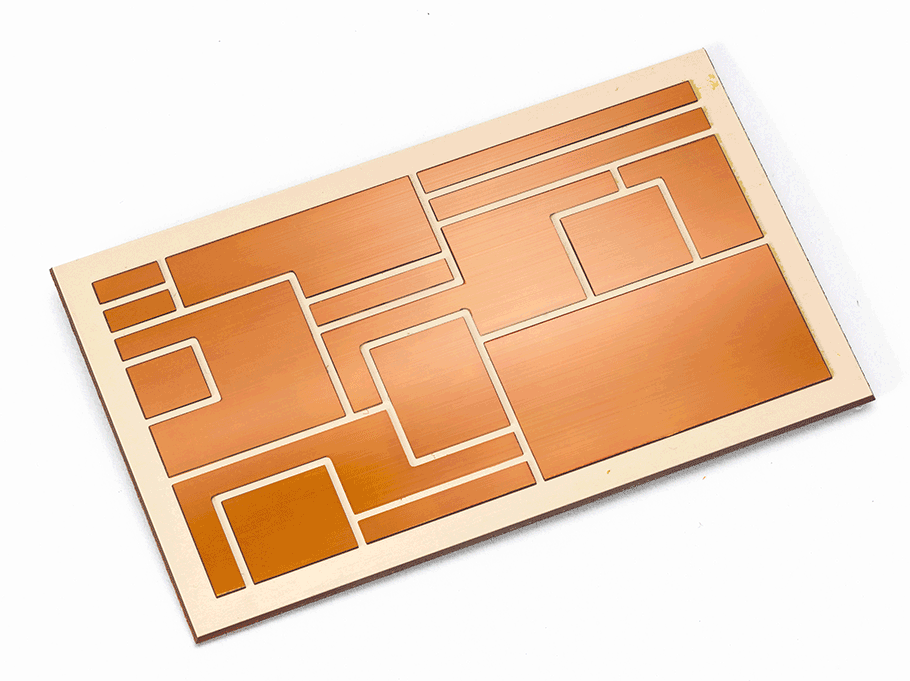

Heat Dissipation Sheet for Insulated Metal Substrates (IMS)

| Item | Test Method | Thermal 15W glade (120,150 μm) |

12W glade (175 μm) |

|

|---|---|---|---|---|

| Thermal Conductivity | W/m·K | Laser flash / 25 ˚C | 17 | 12 |

| W/m·K | Laser flash / 175 ˚C | 15 | 10 | |

| Dielectric Breakdown Voltage | kVrms | AC / 25 ˚C | 9 | 9 |

| Volume Efficiency | Ω·cm | DC, 1 kV / 25 ˚C | 1E+16 | 1E+16 |

| Ω·cm | DC, 1 kV / 175 ˚C | 1E+13 | 1E+13 | |

| Dielectric Constant | - | 1 MHz | 4.5 | 4.5 |

| Dielectric Tangent | - | 1 MHz | ≦0.01 | ≦0.01 |

| Glass Transition Temperature (Tg) | ˚C | DMA | 205 | 215 |

| Modulus of Elasticity (E’) | GPa | DMA / 25 ˚C | 18 | 24 |

| CTE (α1) | ppm/K | TMA, < Tg | 11 | 11 |

| Copper Foil Peel Strength | kN/m | Copper foil (18μm Copper foil) |

0.3 (35μm Copper foil) |

0.3 (35μm Copper foil) |

Remark

- The data given above are not guaranteed values.

Email us about our Division/Department.

Inquiry

Inquiry