Product Introduction

|

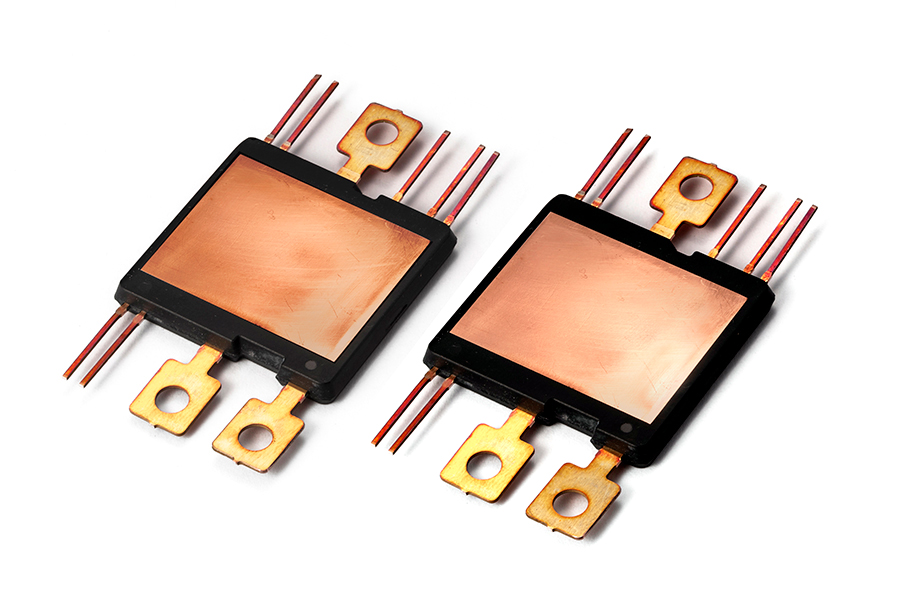

Semi-cured sheet compatible with transfer molding to ensure semiconductor reliability. |

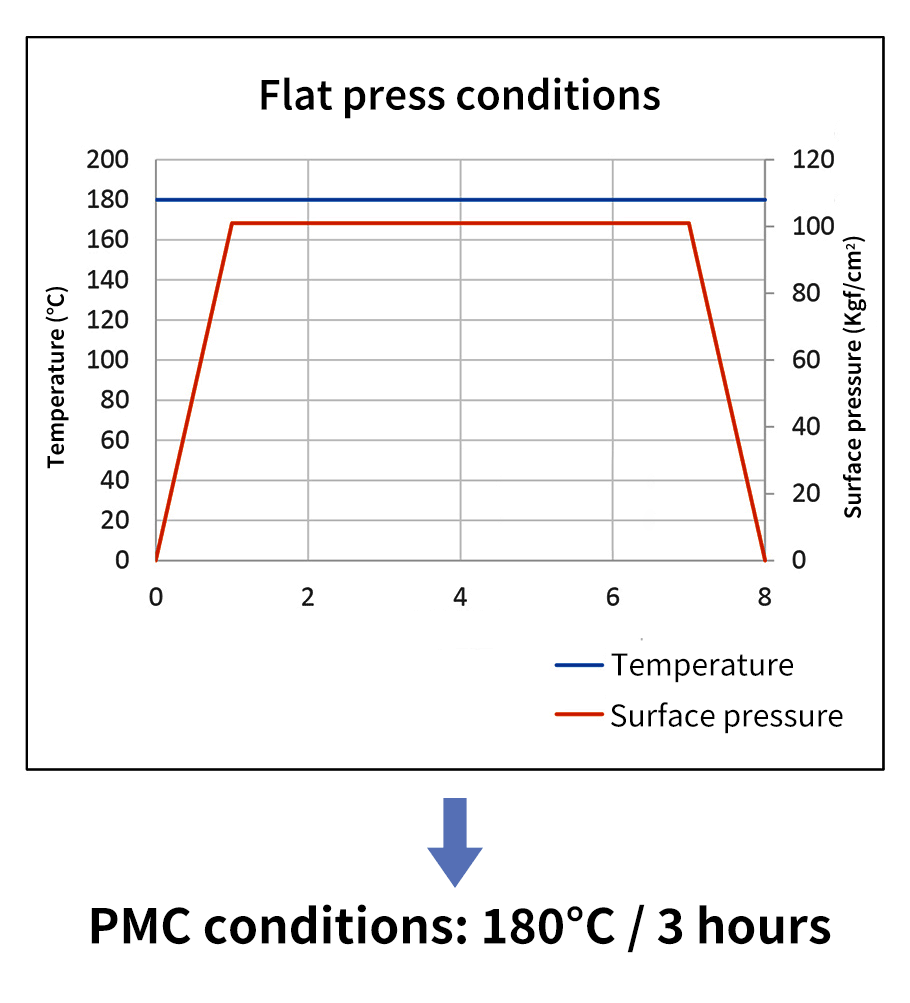

Recommended Molding Conditions for 12W-Glade Sheet Designed for Transfer Molding

- After molding with a flat press, post-cure (PMC) is performed in an oven.

- An example of the temperature/surface pressure profile and PMC conditions is shown below.

- The recommended molding conditions are just one example and serve as a guideline. Adjustments may be necessary based on factors such as the surface condition of the adhered materials, molding machine, internal temperature data from heat sources, product size, and press timing.

General Properties

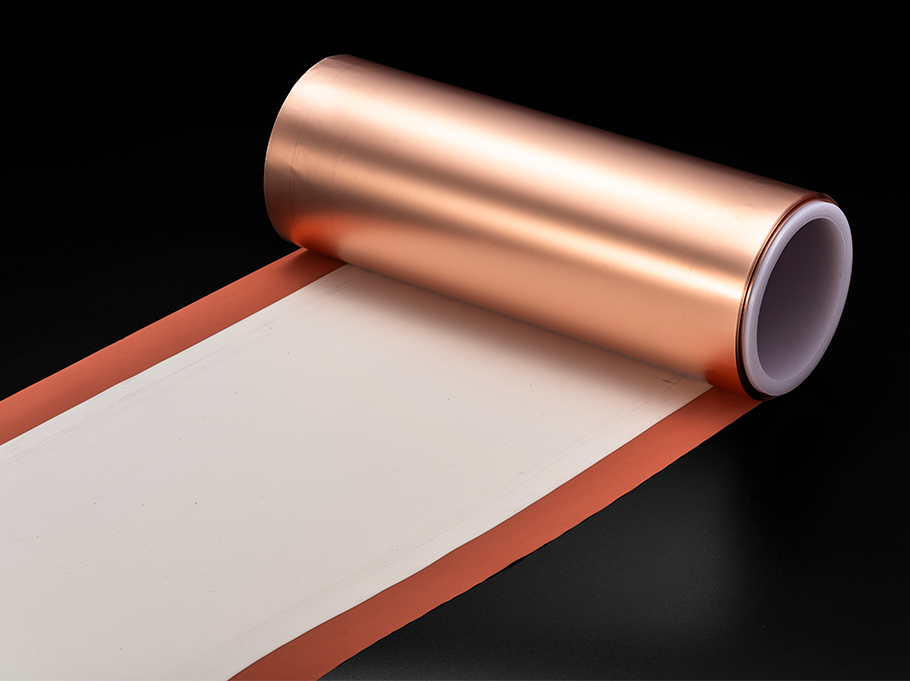

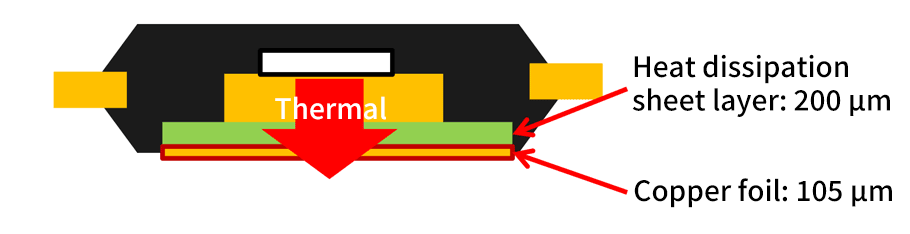

Heat Dissipation Sheet & Heat Dissipation Sheet with Copper Foil

| Item | Test Method | 12W glade (200 μm) |

|

|---|---|---|---|

| Thermal Conductivity | W/m·K | Laser flash / 25 ˚C | 12 |

| Dielectric Breakdown Voltage | kVrms | AC / 25 ˚C | 12 |

| Volume Efficiency | Ω·cm | DC, 0.5 kV / 25 ˚C | 1E+16 |

| Dielectric Constant | - | 1 MHz | 4.6 |

| Dielectric Tangent | - | 1 MHz | ≦0.02 |

| Glass Transition Temperature (Tg) | ˚C | DMA | 220 |

| Elastic Modulus (E’) | GPa | DMA / 25 ˚C | 24 |

| CTE (α1) | ppm/K | TMA, < Tg | 12 |

| Copper Foil Peel Strength | kN/m | 18 μm Copper foil | 0.3 |

Remark

- The data given above are not guaranteed values.

Email us about our Division/Department.

Inquiry

Inquiry