Enhancing promotion of DX,

which is the key to further contribution toward the

SDGs,

fulfilling our mission and responsibilities as a company

Our Group strives to contribute to society through our business activities, and we use the SDGs as indicators for all of our activities. Going forward, it is essential that we promote digital transformation (DX), beginning with AI and IoT, in order to create optimal value for society. This includes pioneering the reforms demanded by the times, such as striving for carbon neutrality and building production systems that do not rely on humans. Let's look at the efforts our Group is making to promote digital transformation and achieve the SDGs.

Masayuki Inagaki

Representative Director, Executive Vice President

Vice Chairperson, Sustainability Promotion Committee

Chairperson, SDG Promotion Committee

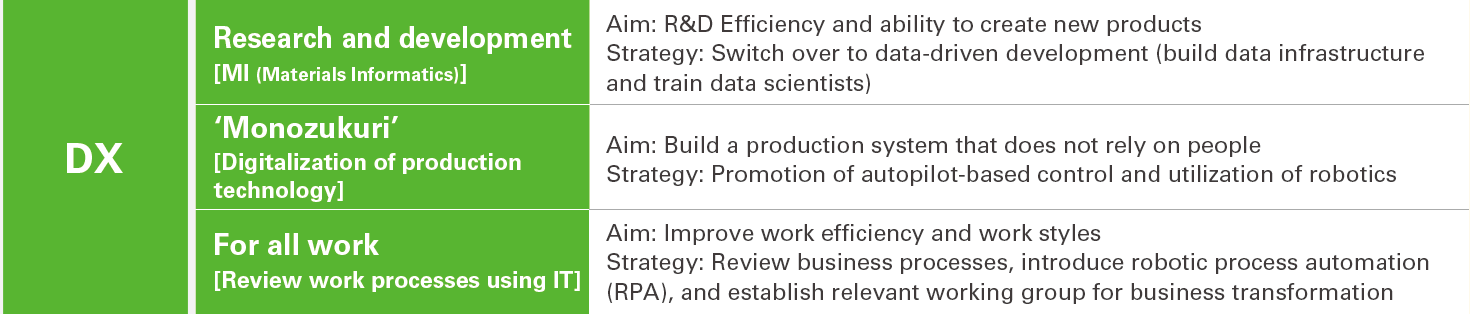

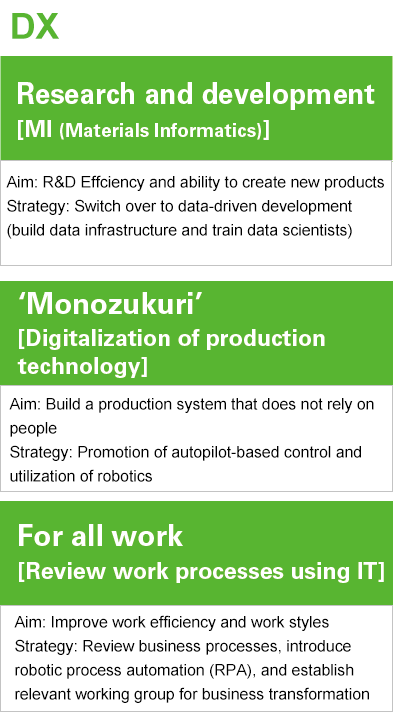

Accelerate Value Creation to Solve Social Issues by Promoting DX

Toward Data-Driven Research & Development through Materials Informatics (MI)

The most significant change brought about by our promotion of DX has been the shift to data-driven research and development. We set out to prevent valuable information from being scattered throughout the company, and build an infrastructure that we can take maximum advantage of in product development. It is now possible for researchers to enter experimental results into a tablet and immediately share them across the company. We are planning to officially launch this system before the end of fiscal 2023.

In addition, we have rolled out web applications capable of easily performing advanced data analysis to all research laboratories where they are used as tools to support research and development.

At the same time, we have prepared tools for utilizing in-house data that enable ordinary researchers to perform advanced analysis techniques like machine learning on their own for tasks such as search materials data. The needs of society are evolving at an accelerating pace, and it is sometimes necessary to make decisions that run counter to conventional wisdom. In such cases, data becomes the basis for decision-making. We are working to spread an appreciation for the importance of data infrastructure throughout the company, and are training MI personnel who can expand its scope of utilization.

These efforts have already achieved a lot, leading to the development of high-performance materials that surpass the results of previous experiments. These include formulations for materials with high heat dissipation properties, and materials for encapsulation of semiconductors that are flexible yet strong and reliable. Some development sites have achieved significant cost reductions without changing the characteristics of existing products, by replacing materials and optimizing process conditions. Each laboratory is also trying to use MI to reduce the number of experiments that need to be performed. In some cases, we have achieved a four-fold increase in efficiency by utilizing a predictive model for screening experimental conditions, which is quite encouraging.

Today's unpredictable world requires us to rapidly develop products with advanced problem-solving capabilities. Replacing our traditional trial-and-error development style with one that utilizes a scientific approach based on vast amounts of internal and external data is sure to dramatically advance materials development where speed is the decisive factor. We aim to achieve both the advanced functionality and environmental friendliness required of next-generation materials, and improve experimental efficiency during their commercialization, through data-based research and development. We hope this will lead to early acquisition of market share.

Full-scale Application Smart Factories, which are a Sure Path to Our Vision of the Future for Manufacturing

We have been promoting digital transformation (DX) in manufacturing around three key pillars: (1) Data collection and storage, (2) Visualization, and (3) Autopilot-based control. Our goal is to build a production system that does not rely on humans. At present, this plan has been implemented at 5 offices in Japan and 5 sites overseas, and is moving forward smoothly.

In production lines, we use various sensors to measure temperature, pressure, flow rate, and vibration to turn this information into digital data. This data is then gathered and made visible through application tools. We carry out quality control for each part number in conjunction with automatic monitoring and autopilot control that notify operators of detected anomalies and the like. We aim to further develop smart factories that do not rely on human workers.

In the manufacturing industry, the declining number of employees due to falling birth rates, and the loss of skills due to seasoned worker retirement, have become issues that can no longer be ignored. We also need to prepare for unforeseen situations such as natural disasters caused by climate change. We want to support societal activity with a manufacturing system that is global in scale, through centralized production information that encompasses all of our overseas sites.

In addition, we plan to actively utilize robotics technology to automate tasks like traverse movement that do not create added value. We have completed the preparatory phase of this project, and expect to implement it within the current fiscal term. Going forward, we plan to roll this out gradually to overseas sites that have become subsidiaries through means such as mergers and acquisitions. We will introduce it as appropriate with consideration for different cultures and values.

Incorporating IT in All Operations and Revamping our Processes to Achieve Efficiency and Work-style Reform

With regard to operational reforms, we have positioned RPA as a key method of promoting digital transformation (DX), and have aimed to foster the growth of development personnel while making operations more effective. As of December 2022, there were 260 robots and a workload reduction in excess of 12,000 hours per year. And, in addition to going paperless, we started to introduce AI-OCR* technology throughout the company during the last fiscal year. By December 2022, we had seen an annual effective reduction of 2,000 hours as a result of automating operations in conjunction with RPA.

The benefits of digitalization go beyond just workload reduction and improved efficiency. I feel that we are creating a virtuous cycle that encourages work-style improvements, such as reducing stress by liberating workers from the excessive tension of working in an environment that does not tolerate mistakes.

In addition, we are now rolling out a no-code tool to the entire company that enables the development of applications without the need for special knowledge or programming skills. This makes it possible for each department to build simple systems without having to rely on the systems department. We are focusing on this system as an effective means of discovering and cultivating DX-capable personnel, and are working to expand its use.

At the same time, we are making efforts to encourage employees to see themselves as the leaders of operational reforms. This entails establishing working groups where employees formulate a vision for each department and review its processes. Then based on the themes which emerge from each working group, they consider for themselves what are the best digital technologies for replacing the operations they wish to make more efficient. We believe it is important for employees to pursue the goals set by the company for improving operational efficiency, while also taking the initiative to make improvements on their own.

- * AI-OCR: An optical character recognition technology that incorporates AI.

Commitment to Training Data Scientists throughout the Company who Have a Manufacturing Mindset

We plan to assign data scientists to a wide range of departments within the company beyond just research laboratories, with the goal of promoting data-driven product development. We conducted a one-year-long in-house training program over three terms for a total of more than 50 employees. We intend to establish an internal data scientist certification system by the end of fiscal 2023, and aim to certify 20% of our technical personnel by the end of fiscal 2025.

It is imperative that we secure capable MI personnel in order to handle the remarkable advance of our data-driven society. Since we went into business as a pioneer in plastics, our Group has continued to lead the industry with innovative technologies. We have formed projects led by young employees with the goal of developing personnel with advanced skills and pride in the kind of manufacturing that is unique to Sumitomo Bakelite. These members handle everything from planning to implementation for the training programs conducted at each level. We expect the efforts of young data scientists to be a source of future development. We intend to further increase our presence on the global market, where we have an outstanding market share by building on a solid structure rooted in the wealth of experience possessed by veteran employees.

Improving Corporate Value by Leveraging Our Strengths to Contribute to Achieving SDGs

Fulfilling the Responsibility and Mission of a Global Company to Contribute toward SDGs

Our Group has strived to enhance our framework since we launched our first initiatives for the SDGs in 2018. We established the Sustainability Promotion Department in April 2023 to further enhance our efforts, and intend to work harder than ever to help achieve the SDGs.

Out of the 17 goals and 169 specific targets for achieving those goals that constitute the SDGs, we initially designated 6 SDGs toward which we can leverage the strengths of our field of business as priority SDGs. We then added SDG 13 on "taking specific measures against climate change," and are developing our business activities with our sights set on "6+1" priority SDGs. Innovation is essential to measures to address climate change, including achieving carbon neutrality. I believe that the opportunities to make a contribution through our products will continue to increase. We plan to further expand our product lineup with products whose features allow them to immediately respond to the complex and diversifying demands of society.

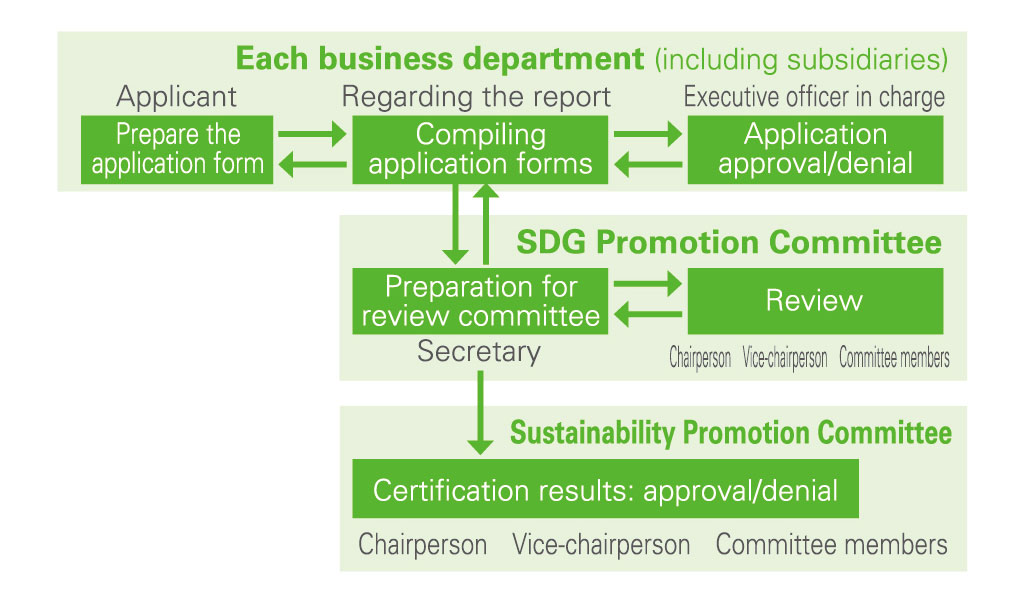

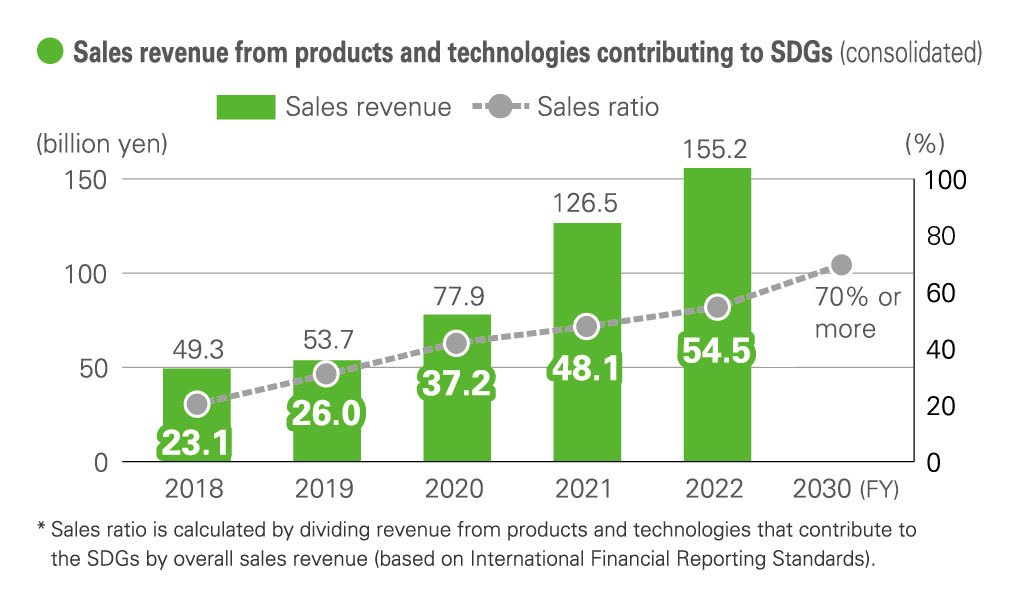

Our Group is pursuing certification of SDG-contributing products, technologies, and activities. In fiscal 2022, 29 products and 1 technology were newly certified, bringing the total number certified to 148 products, 2 technologies, and 2 activities. Regarding "SDG-contributing products," we have set long-term goals of a 50% or more contribution to revenue in 2023 and 70% or more in 2030. Our actual result for fiscal 2022 was 54.5%, meaning we managed to achieve our goal for fiscal 2023 ahead of schedule.

The development and certification of SDG-contributing products is also vital to future business development. The assessment criteria are that the target must be appropriately selected, and a concrete explanation of contributions must be provided, including objective figures based on actual data and publicly disclosed information. Only products that meet the requirements are certified after approval by internal committees. The products certified in fiscal 2022 include bio-based materials such as phenolic resins using biomass-derived lignin that feature high strength and high heat resistance comparable to petroleum- derived resins, and furan resin made from raw material components derived from sources like corn cobs.

We are also working to raise awareness by conducting e-learning for all employees, and displaying the SDGs icon everywhere within the company. The idea is to focus on awareness-raising activities that cultivate a sense of ownership by getting each person to always think about which goals their work and actions correspond to.

Furthermore, we place particular emphasis on strengthening governance as part of our efforts to achieve the SDGs. As a company that operates globally, we engage in socially responsible procurement, and do not use raw materials obtained through unfair means such as child labor or forced labor. We will fulfill our mission and responsibility as a company to help achieve the SDGs, which are the common goals of the world.

● Typical SDG-Contributing Products

Having a Positive Impact on Society by Clearly Quantifying Environmental Measures

Under our current Environmental Vision for 2050 (net zero), we have set goals of reducing CO2 emissions by 46% or more (compared to fiscal 2013) by 2030, and the 2050 target of taking on the challenge of achieving carbon neutrality by 2050. We are striving to reduce CO2 emissions by installing solar panels and expanding our use of electricity from renewable energy. In fiscal 2022, we achieved a 64.7% reduction in CO2 emissions in Japan, and a 39.3% reduction if including overseas operations (compared to FY2013 for both Japan and overseas). In Japan, we achieved this goal ahead of schedule.

Our Group has also formulated a company-wide environmental development through 2035 that covers the five areas of (1) Resources, (2) Energy Creation/Energy Conservation, (3) Long Service Life, (4) The 3Rs, and (5) Environmental Measures. Concerning (1) Resources, we are starting from biomass materials to develop plastics that are not derived from petroleum, and trying to develop a line of core products that do not depend on petrochemical resources. For (2) Energy Creation/Energy Conservation, we are pursuing technological innovation in materials with features such as weight reduction and heat management. For (3) Long Service Life, we aim to extend product service life by improving durability and reliability. Regarding (4) The 3Rs (Reduce, Reuse, Recycle), we are aiming for the early establishment of technologies that contribute to a resource-recycling society. And with respect to (5) Environmental Measures, we are focusing our efforts on CO2 emissions reductions and material conversion, and on eliminating environmentally hazardous substances from our main products.

From an environmental perspective, many people have a negative image of plastics. We believe that it is important to demonstrate environmental performance using clear, specific numerical values if we want to change this situation and exhibit a positive presence in society. We also plan to apply LCA (Life Cycle Assessment) to all products by the end of fiscal 2024.

We will work even harder to ensure that people have an accurate understanding of the indispensable value plastics bring to society, by pursuing values that support lifestyles that are safe, comfortable, and secure, and by making full use of our unique recycling technology to spread adoption of the 3Rs.

Certification Process, Results, and Targets for SDG-contributing Products, Technologies, and Activities

Since fiscal 2018, Sumitomo Bakelite has been accrediting products, technologies, and activities that contribute to the SDGs as SDG-contributing products, SDG-contributing technologies, and SDG-contributing activities.

[Products Eligible for Certification]

Certification is intended for products that meet one or more of the following certification requirements (1)-(8)

| (1) | Goal 3: The product promotes health and welfare |

|---|---|

| (2) | Goal 7: The product contributes to improving energy efficiency and realizing modern energy (including energy storage) |

| (3) | Goal 8: The product contributes to realizing decent work and economic growth |

| (4) | Goal 9: The product contributes to the realizing decent work friendly technologies, and to the foundation of industry and technological innovation |

| (5) | Goal 12: The product contributes to reducing waste (including food waste) and harmful substances, contributes to reducing environmental impacts, and contributes to the realization of recycling and resource saving |

| (6) | Goal 13: Measures against climate change, and things that help strengthen adaptive capacity to climatic and natural disasters |

| (7) | Goal 14: The product contributes to the conservation and utilization of marine resources and to the prevention and reduction of marine pollution |

| (8) | The product contributes to the achievement of one or more of the 17 SDGs other than Goals 3, 7, 8, 9, 12, 13, and 14 listed above. |

|---|

[Fiscal 2022 results]

Sales revenue 155.2 billion

Sales ratio 54.5 %

[Target]

Fiscal 2030 sales ratio 70 % or more

[Certification process]

Items reviewed and assessment criteria

- Concrete explanation of contributions: Presented through objective figures based on actual data or publicly disclosed information.

- Targets for contributing to SDGs: Selected appropriately

Any negative impacts due to the product are also discussed before certification.

Topics More

- 2024/02/01 Sustainability Sumitomo Bakelite Co., Ltd. announces its establishment of “Human Rights Policy for the Group of Sumitomo Bakelite Co., Ltd.”

- 2023/10/31 Sustainability Integrated Report 2023 of Sumitomo Bakelite Co., Ltd. has been issued.

- 2023/06/21 Sustainability Selected as an iSTOXX® MUTB Japan Platinum Carrier 150 Index

- 2022/10/31 Sustainability Integrated Report 2022 of Sumitomo Bakelite Co., Ltd. has been issued.

- 2022/10/14 Sustainability Sumitomo Bakelite Co., Ltd. Receives Gold Medal in EcoVadis Sustainability Assessment

- 2022/05/27 Sustainability Participation in the 30by30 Alliance for Biodiversity

Inquiry

Inquiry