April 10, 2025

Sumitomo Bakelite Co., Ltd. (TOKYO: 4203 HQ: Shinagawa-ku, Tokyo, President and Representative Director: Kazuhiko Fujiwara) is pleased to announce the development of a mono-material film made of a polyethylene-based material, taking advantage of the company's resin blending and co-extrusion multilayer film processing technology. Having now completed development, we aim to begin mass production and sales of this easily recyclable packaging material for medical device packaging in fiscal year 2025.

Background

In recent years, it has become necessary to address environmental issues such as climate change and resource depletion. Under these circumstances, there is a growing need for recyclable packaging materials as one way of reducing packaging waste.

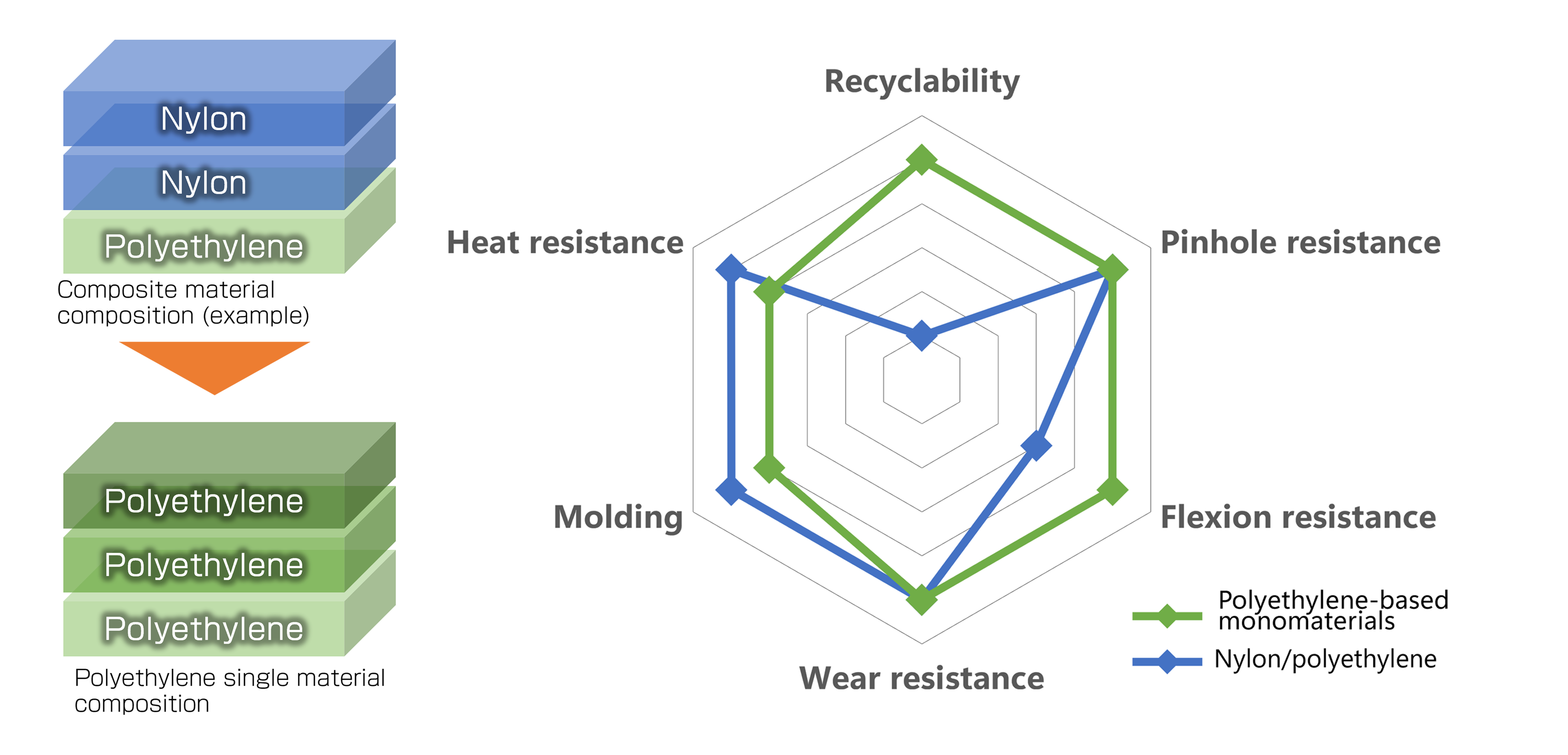

Currently, composite films made of different materials are widely used, combining different materials in layers to achieve excellent functions such as light weight, high strength, moisture resistance and storage stability. However, because the different materials are combined in a complex manner, it is difficult to separate the individual materials, making recycling extremely difficult. As a result, when they are disposed of as waste, they are often incinerated, which increases the environmental burden by emitting carbon dioxide (CO2) and other greenhouse gases, and this is considered a problem.

To address these issues, it is essential that companies and consumers work together to realize a circular economy that aims to use resources efficiently and minimize waste. In Europe, regulations and guidelines are already being established by governments and international organizations, and specific policies are being implemented to reduce plastic waste and increase recycling rates.

Packaging material for medical devices: SUMILITE® CEL (polyethylene mono-material film)

|

In response to this market demand, Sumitomo Bakelite has been developing a film that is made from a single material and has sufficient strength and formability required for packaging materials. By utilizing our many years of co-extrusion multi-layer film processing technology and making the film from a single polyethylene material, we have developed a mono-material film that has improved recyclability while also providing the heat resistance, easy peelability, pinhole resistance, and thermo-formability that are important for medical device packaging, which is the target of this development. Customers can use the mono-material film in the same conditions as their current mixed-material

composite films, and can reduce the environmental impact by recycling medical device packaging. |

|

Product features

|

|

Specifications

| Items | Test method | Unit | Direction | CEL-9530A |

| Thickness | - | µm | - | 150 |

| Tensile Strength | JIS K 7127 | N/mm2 | MD | 49 |

| TD | 43 | |||

| Elongation | JIS K 7127 | % | MD | 776 |

| TD | 762 | |||

| Tear strength | JIS K 7128 | N/cm | MD | 1198 |

| TD | 1170 | |||

| Light transmittance | JIS K 7361 | % | - | 89 |

| Haze | JIS K 7136 | % | - | 15 |

Remark

- The values mentioned above are typical, not guaranteed.

Related Information

For inquiries on this information

Corporate Communications Department, Corporate General Affairs Division, Sumitomo Bakelite Co., Ltd.

TEL: +81-3-5462-3430