Sumitomo Bakelite Co., Ltd.

Sunbake Co., Ltd.

October 9, 2024

Sumitomo Bakelite Co., Ltd. (Head Office: Shinagawa-ku, Tokyo; President: Kazuhiko Fujiwara) is pleased to

announce that its group company, Sunbake Co., Ltd., which manufactures and sells wood-based adhesives, has

launched commercial sales of the “Sumitac® PL-700 Series,” a lignin-modified phenolic resin in which a portion

of the phenol—a raw material derived from fossil resources—has been replaced with lignin, a renewable raw

material derived from non-edible biomass, for phenolic resin production.

This product is one of the research outcomes of a project commissioned by NEDO (New Energy and Industrial

Technology Development Organization).

Background

Plywood and laminated veneer lumber, made from wood, are expected to see increased adoption as an approach to reducing greenhouse gas emissions and achieving carbon neutrality. Adhesives essential for producing these wood-based materials are currently derived from fossil resources, highlighting the need to transition to renewable resources and reduce greenhouse gas emissions.

|

Anticipating future environmental requirements for its core phenolic resin products, Sumitomo Bakelite Co., Ltd. began basic research on the use of lignin in resins prior to 2010. Through this research and participation in NEDO-commissioned projects—“Development of Basic Technologies for Green and Sustainable Chemical Processes / (4) Development of Innovative Green Technologies that Enable Conversion and Diversification of Chemical Raw Materials” (FY2010–2012) and “Development of Process Technology for the Production of Non-Edible Plant-Derived Chemicals” (FY2013–2019)—our company has been developing fundamental technologies for synthesizing resins using various types of lignin, with the goal of industrial applications. As part of its efforts to promote the transition from fossil resources to renewable resources, our company has advanced the development and mass production of resol-type lignin-modified phenolic resins utilizing lignin, a non-edible biomass. |

Resol type lignin-modified phenolic resin |

About Sumitac® PL-700 Series

Plywood test specimens using this resin |

The Sumitac® PL-700 Series is a phenolic resin adhesive designed for the manufacture of plywood and laminated veneer lumber. In this series, a portion of phenol— a raw material sourced from finite fossil resources—has been replaced with lignin, a renewable raw material derived from non-edible biomass that is considered sustainable. |

About Sumitac® PL-701

|

Sumitac® PL-701, a product within the Sumitac® PL-700 Series, has been certified with the Biomass Mark as defined by the Japan Organic Resource Association.

|

|

Future Plans

By leveraging this innovative material in our business and expanding its market presence, we aim to

contribute to building a sustainable society.

Furthermore, to accelerate progress toward carbon neutrality, we will continue to promote its social

implementation and broaden its adoption.

Estimated Environmental Effects

- The use of this product, which contains 15% biomass content, can reduce the

consumption of raw materials sourced from fossil resources by 15%.

- The table below shows the results of a Carbon Footprint (CFP) comparison conducted at our company’s production facilities between the PL-700 Series and our existing products. - Compared to our existing products, the PL-700 Series demonstrates a 17% reduction in CFP. Since the PL-700 Series can be used under the same operating conditions as existing products, replacing 100 tons per month of existing products with the PL-700 Series is projected to achieve a total CFP reduction of 29 tons of CO2 equivalent per month.

| Mass production scale manufacturing | PL-700 series | Our company existing products | |

|---|---|---|---|

| Characteristics | Resin composition | Lignin/phenol | Phenol |

| Biomass Content 1) | 15% | 0% | |

| CFP (per kg of resin)2) | 1.38kg (CO2 eq/kg) 2) | 1.67kg (CO2 eq/kg) | |

| Benefits | CFP Reduction Rate | 17% | ー |

| CFP Reduction (per kg of resin) | 0.29kg (CO2 eq/kg) | ー | |

| CFP Reduction (100 tons/month of resin consumption) | 29ton (CO2 eq/月) | ー | |

|

|

- These values are for reference purposes only value and have not been certified.

- The values provided above are representative and are not guaranteed.

- This estimate is based on the information available at the time of calculation and does not guarantee future results.

- This estimate is provided exclusively for the purpose of evaluating the adoption of our company’s resin and does not grant permission to disclose this information to third parties.

[Plywood Properties]

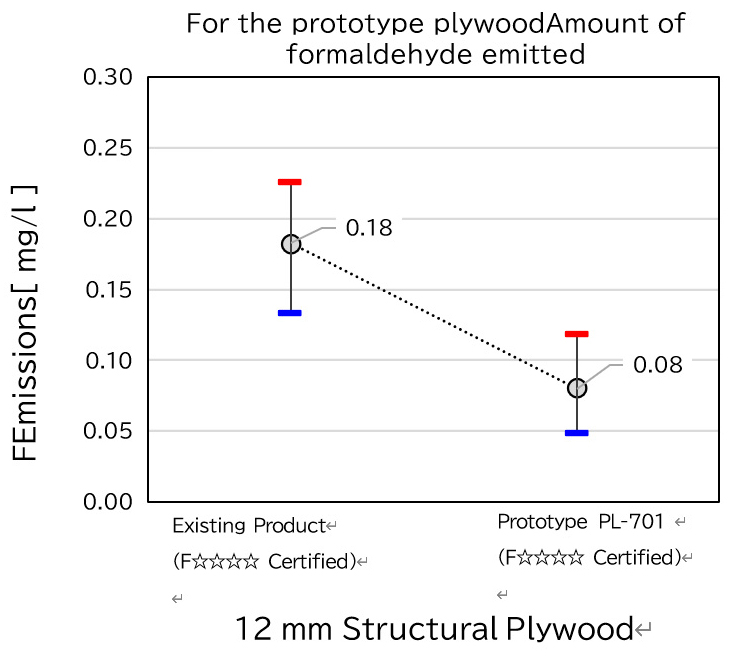

The formaldehyde emissions from structural plywood bonded with Sumitac® PL-701 as an adhesive is lower than

that of our existing products. Other plywood properties also meet JAS standards.

These favorable results are not limited to plywood but are also applicable to other uses such as laminated

veneer lumber.

|

|

Sunbake Co., Ltd. was established to manufacture and sell adhesives for wood processing, construction, and

civil engineering materials.

The company manufactures and sells various adhesives, including those for plywood, particleboard, fiberboard,

and composite materials, as well as binders for rock wool.

Related Information

Inquiries:

Sales Division, Sunbake Co., Ltd.

TEL: +81-3-5462-4933

E-mail: sunbake@ml.sumibe.co.jp