September 15, 2021

Sumitomo Bakelite Co., Ltd. (Head Office: Shinagawa-ku, Tokyo; President: Kazuhiko Fujiwara) announces launch of its substrate material series "LαZ" roll core material volume manufacturing in Utsunomiya, Japan for reel-to-reel substrate production

Background

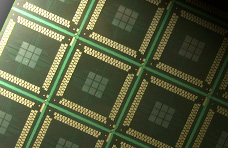

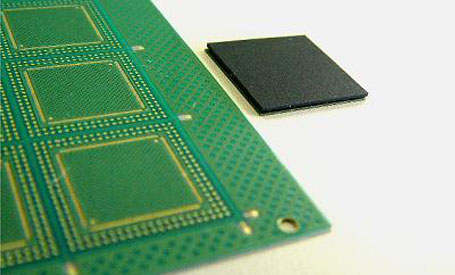

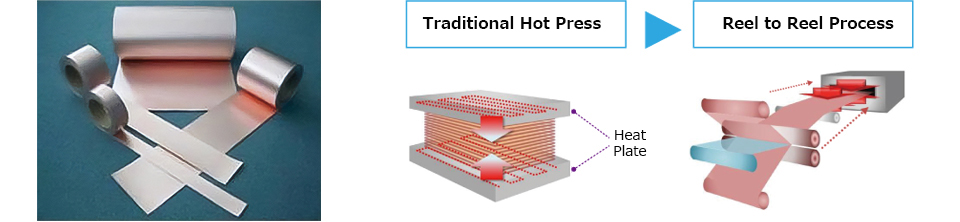

Until now, our company has been manufacturing and selling semiconductor package substrate materials (LαZ series) featuring low thermal expansion, high rigidity and high elastic modulus. Core materials (*1) are generally manufactured by setting copper foil on both sides of a prepreg (*2) and press forming and curing it by heat press in large panel form on the other hand, thinner substrates are required because of thinning trend of IC packages and the thickness of core materials used in the substrates are becoming thinner. However, from substrate manufacturing point of view, the thinner the core material is, the more difficult it is for substrate and PCB manufacturers to handle it, and there is a concern that the yield will decrease.

In addition, the number of manufacturers that can handle thin material is limited and that leads to future supply and cost reduction concerns. We can offer not only sheet type but also roll type core material by using an innovative production method.

- (*1) Core material: an insulating plate obtained by superposing a sheet impregnated with a resin into a base mateiral such as glass cloth and subjecting it to pressure and heat treatment

- (*2) Prepreg: Sheet prepared by impregnating a glass cloth with resin

Feature

Under these circumstances, the reel-to-reel continuous substrate production method (often used in flexible circuit board) by using our roll-type core material would be the good solution for those concerning. Continuous substrate production by reel-to-reel without manual work can expect higher yield and the material waste is expected to be reduced. Also material utilization will be enhanced and higher area yield is expected as well. Our roll-type core material for ultrathin double-layer substrates has been adopted for mass production for the first time thanks to the cooperation of the substrate manufacturer who agreed with the above concept and in conjunction with the market demand mentioned above. Our innovative production method not only has great potential to solve various problems in the production of ultrathin substrates in the future, but also can provide core materials of 20 um or less, which is difficult to produce with conventional press production methods. Our company aims to achieve sales of 3 billion yen in fiscal 2025 by targeting ultra-thin 2-layer substrates for use in devices that are expected to show significant growth in the future, such as display and memory markets.

Main Applications

- Memory (NAND, DRAM), MINI-LED, MiniLED backlight for LCD, MEMS

Related Information

For inquiries on this product:

Sumitomo Bakelite Co., Ltd., Information & Telecommunication Materials Div.

Tel:+81-3-5462-4015