October 23, 2025

Sumitomo Bakelite Co., Ltd. (Headquarters: Shinagawa-ku, Tokyo; President and Representative Director: Shinichi Kajiya) has developed SUMILITERESIN™ PR-56531, an amide-modified phenolic resin that excels in wear resistance for use as a binder resin in automotive brake pads. The use of this product is expected to reduce the emission of brake dust, which will be regulated under Euro 7 emissions standard. Through this product that contributes to reducing environmental impact, we aim to help realize a sustainable society.

Background of Development

In recent years, stricter rules have been introduced to control harmful substances emitted by vehicles in an effort to tackle air pollution. Euro 7 emission standards, scheduled to begin in 2028, will also regulate the amount of particles emitted by brake friction, and further regulations are expected in the future. As a result, there is an urgent need to develop brake systems that emit less wear particles, particularly for vehicles intended for the European market.

To address this need, we have developed a new wear-resistant binder resin for automotive brake pads, the amide-modified phenolic resin SUMILITERESIN™ PR-56531.

Features of Wear-Resistant Amide-Modified Phenolic Resin: SUMILITERESIN™ PR-56531

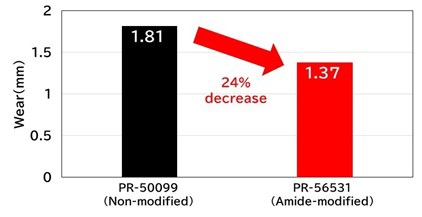

Our newly developed wear-resistant amide-modified phenolic resin, SUMILITERESIN™ PR-56531, contributes to improving the wear resistance of brake pads. In our internal dynamometer tests using brake pad models, we confirmed that this resin reduces the wear amounts by 24% compared to our conventional non-modified phenolic resin.

This product is compatible with conventional friction material manufacturing processes. It enhances wear resistance without compromising the friction performance.

In addition, this product is also able to be produced at our overseas facilities, enabling local supply from regions such as China, Southeast Asia, Europe, and the US. We have established a system to respond quickly and flexibly to the global needs of our customers.

Powdered Wear-Resistant Amide-Modified Phenolic Resin (Left)

Brake Pad (Right)

Wear Resistance Data for Brake Pad Model

Test Conditions: Initial braking speed 100 km/h, Braking deceleration 3.5 m/s2, Pre-braking temperature 300°C, Number of braking cycles 300 times

Note: The above data reflects internal evaluations conducted using a 1/10 scale dynamometer.

Environmental Impact Reduction and Sustainability

SUMILITERESIN™ PR-56531 helps reduce brake dust emissions by improving the wear resistance of brake pads. By preventing air pollution and lowering environmental impact, this product contributes to the development of a sustainable society.

Future Plans

We aim to expand the market share of SUMILITERESIN™ PR-56531 as a high-performance binder resin for friction materials, focusing especially on the European market. Currently, this product is being evaluated at domestic and international brake pad manufacturers to comply with Euro 7 emissions standard, which will begin in 2028. We are targeting the start of mass production and sales by 2027, with a goal of achieving annual global revenue of 1 billion yen.

In addition to addressing Euro 7 compliance, our group is working to expand our product lineup to meet the demands for reduced environmental impact, sustainability, and advanced brake performance in response to vehicle electrification. We are particularly focused on developing next-generation products, including technologies for short-time molding and the use of biomass materials.

Related Information

![]() Announcement of the Development of Wear-Resistant Phenolic Resin for Brake Friction Materials(545KB)

Announcement of the Development of Wear-Resistant Phenolic Resin for Brake Friction Materials(545KB)

[Contact information]

Polymers Sales Department, Material Solutions Sales Division, Sumitomo Bakelite Co., Ltd.