Description

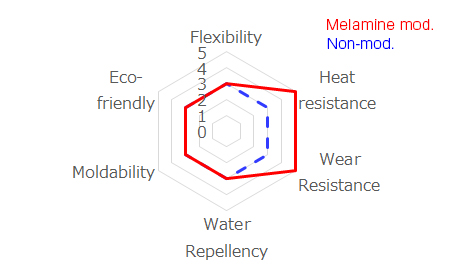

This is a binder resin for brake friction materials with excellent wear resistance. It contributes to reducing brake dust regulated under Euro 7 and preventing air pollution.

Features

✔ Wear resistance

Main Grades

| Grade | Modified Type | Features | Flow 125℃, mm |

Gel Time 165℃, sec |

Free Phenol |

|---|---|---|---|---|---|

| PR-56341 | Melamine-Silicone modified | Wear resistance, Heat resistance, Crack resistance |

30 | 40 | <1.0 |

| PR-56531 | Amide modified | Wear resistance, SVHC-free | 25 | 15 | <1.0 |

- The values in this material are the representative values.

Technical Data

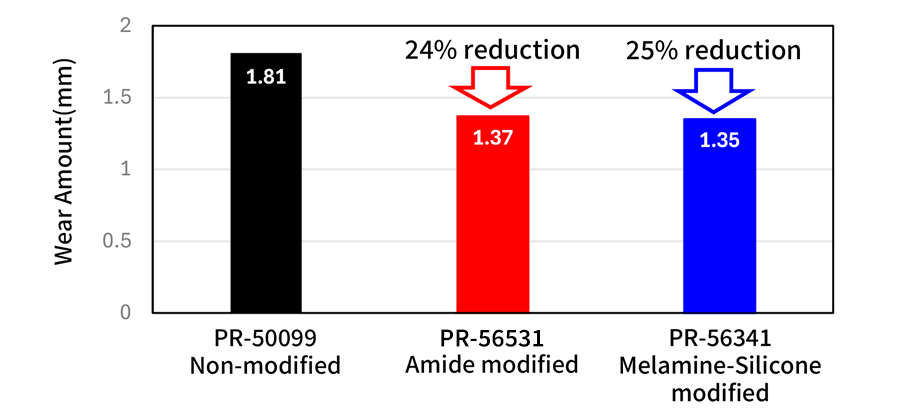

Wear resistance data

・1/10 Scale dynamo

・100km/h, 3.5m/s2, IBT 300℃, 300cycle

- -Friction Material Composition :

- Resin/Aramid fiber/Potassium titanate/Barium sulfate/Cashew particle= 20/5/7/60/8 vol%

- -Molding Conditions :

- Hot press150℃/5min @25 MPa, Baking: 200℃/3hr

- -Test Conditions :

- Initial braking speed 100 km/h, Braking deceleration 3.5 m/s2, Pre-braking temperature 300°C, Number of braking cycles 300 times

Inquiry

Inquiry