September 10, 2025

Sumitomo Bakelite Co., Ltd. (Headquarters: Shinagawa-ku, Tokyo; President and Representative Director: Shinichi Kajiya) is pleased to announce the expansion of its product lineup of the tribological and high-heat-resistant phenolic resin molding compounds, “SUMIKON® PM-5700 series.” This series has been increasingly adopted for applications such as bearings in electric pumps, which have gained prominence with the electrification of automobiles. As electric pumps evolve to deliver enhanced functionality, there is a growing demand for tribological components with improved durability under high-temperature and high-load conditions, as well as a need to reduce CO2 emissions. The SUMIKON® PM-5700 series is positioned as an effective material to address these needs and we aim to further expand its market reach.

Background of Development

As the electrification of automobiles progresses, there is an increasing demand for enhancing the performance and optimizing the cost of in-vehicle electric pumps, such as electric water pumps (EWPs)*1, electric oil pumps, and electric vacuum pumps, as well as reducing the CO2 emissions associated with the materials used in the manufacturing of these pumps. For example, the bearings used in EWPs, which play a critical role in cooling batteries and heat-generating electronic components, often employ high-cost materials such as sintered carbon or PEEK (polyether ether ketone) containing PTFE, which is a type of PFAS.

However, these materials present challenges, including high CO2 emissions during production. Sintered carbon often involves extensive processing steps, leading to higher component costs, while PEEK may melt due to frictional heat on sliding surfaces. Pump manufacturers are increasingly seeking high-durability materials for bearings to support higher pump output and are actively exploring new designs and materials.

*1 Electric Water Pump (EWP): A pump that circulates coolant using an electric motor.

About the SUMIKON® PM-5700 Series

|

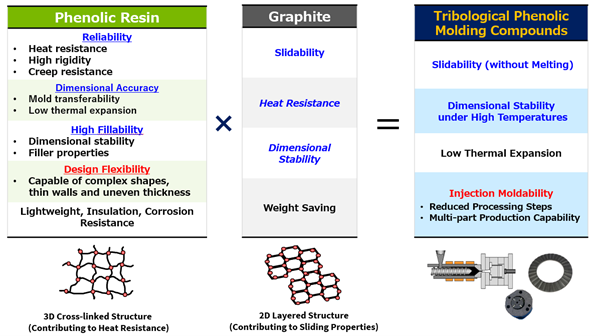

The SUMIKON® PM-5700 series is a tribological, high-heat-resistant phenolic resin molding compounds that combines heat-resistant phenolic resin with graphite for enhanced tribological performance. Through our proprietary formulation, we have achieved a high-heat-resistant plastic that slides without melting. Additionally, this product series supports injection molding, enabling thin-wall and uneven-wall molding by leveraging the low viscosity characteristics of thermosetting resins during melting, which enhances design flexibility. |

|

Future Plans

Through the sale of tribological, high-heat-resistant phenolic resin molding compounds, we aim to capture customer needs and leverage our core strength in resin development to actively pursue the creation of new products with even lower friction performance for high-temperature and high-load applications. In the field of tribological molding compounds, our goal is to achieve annual sales of 2 billion yen by the fiscal year 2030.

Key Features of the Product

This product offers high wear resistance and is suitable for tribological components in machinery, such as pump parts. As a thermosetting resin, it does not melt or adhere due to frictional heat. Additionally, it features minimal dimensional changes in high-temperature environments or when submerged in coolant.

Table: Characteristics of tribological Phenolic Resin

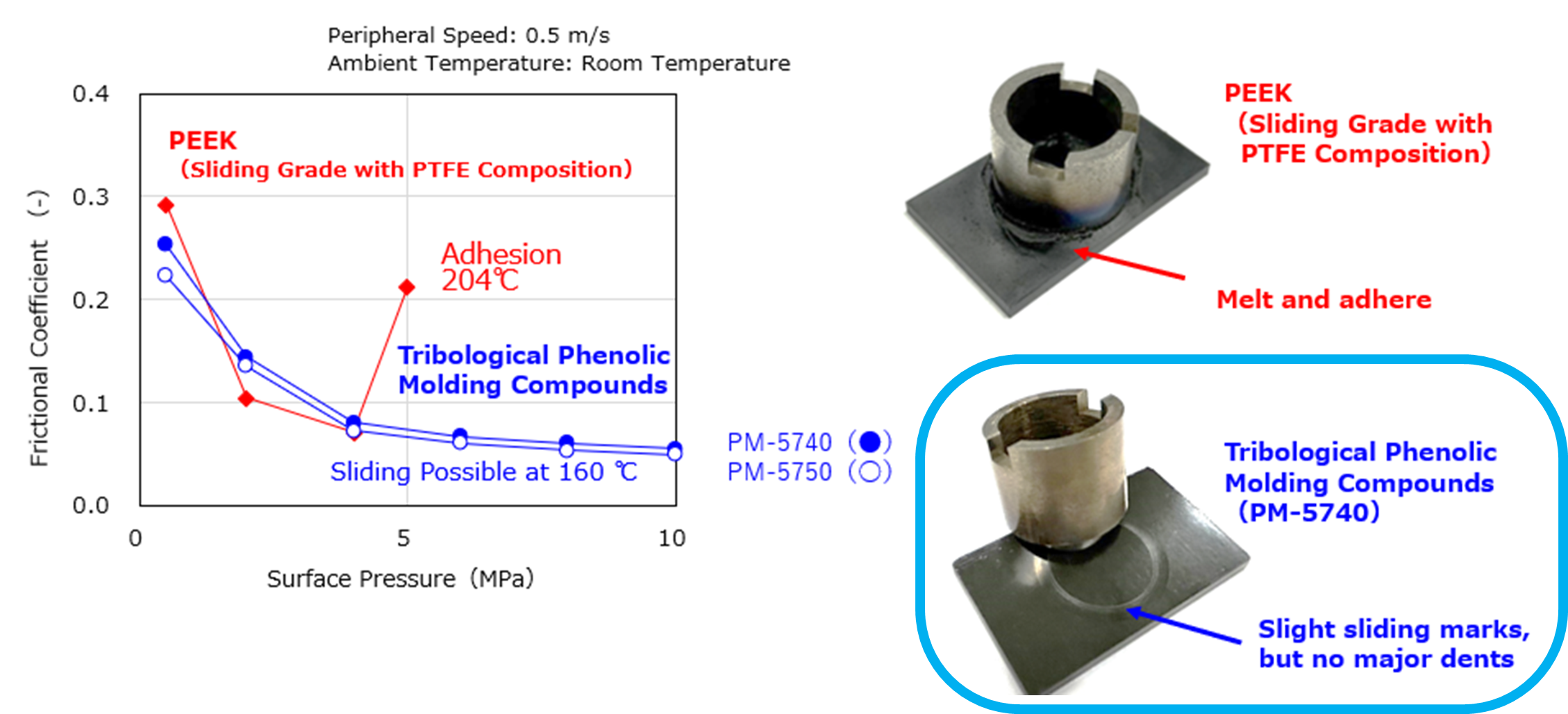

Figure: Comparison Between PTFE-Compounded PEEK Material and High-Sliding Phenolic Molding CompoundsResin

A test was conducted by placing a metal ring (S45C) on a resin plate, applying surface pressure and rotating the ring. PEEK, commonly used for sliding components, showed adhesion and increased friction resistance as the surface pressure increased. In contrast, our tribological molding compounds maintain excellent sildability even under high temperatures.

Technical Data

| Item | Phenolic molding compounds | Sintered carbon | PEEK Thermo plastic |

|||

|---|---|---|---|---|---|---|

| PM-5750 | PM-5740 | PM-5780 | PM-5640 | |||

| Low friction Low wear |

Low friction | Low friction Low warpage |

Low friction High strength |

|||

| Specific gravity | 1.67 | 1.65 | 1.61 | 1.78 | 1.77 | 1.45 |

| CTE (ppm/K) |

20 | 22 | 25 | 21 | 23 | 45 |

| Flxeural strength (MPa) |

90 | 90 | 90 | 180 | 75 | 230 |

| Flxeural modulus (GPa) |

13.5 | 13 | 12 | 15 | 15 | 11.5 |

| Compressive strength (MPa) |

160 | 160 | 150 | 300 | 175 | 170 |

| Frictional coefficient (0.6MPa, 5m/s) |

0.1 | 0.12 | 0.12 | 0.2 | 0.14 | 0.23 |

| Comparative abrasion quantity mm/(MPa・m/s・hr) |

2×10-3 | 3.5×10-3 | 5×10-3 | - | - | - |

| TG (°C) | 200< | 200< | 200< | 200< | - | <150 |

- The above data is for reference only. For phenolic molding compouds, test piecies are prepared by injection molding, and tested according to ISO standards after annealing.

- Abrasion tests are tested with S45C.

Realization of Reduced Environmental Impact

In recent years, increasing emphasis has been placed on environmental considerations, including carbon neutrality. In this context, the SUMIKON® PM-5700 series contributes significantly to reducing environmental impact by drastically lowering energy consumption during production compared to sintered carbon. According to our internal estimates*2, the product’s carbon footprint (CFP) is expected to be reduced to less than one-tenth that of sintered carbon, making a substantial contribution to the pursuit of carbon neutrality.

*2 Based on the assumption of components with identical shapes and calculated using the environmental impact coefficient data book (3EID) derived from the input-output table for the “carbon and graphite products” category.

Related Information

[Contact information]

Materials Solution Sales Division

Sumitomo Bakelite Co., Ltd.