MobilityMiniaturization and Light Weight

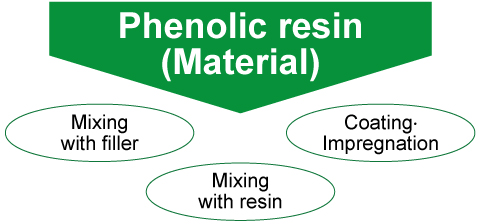

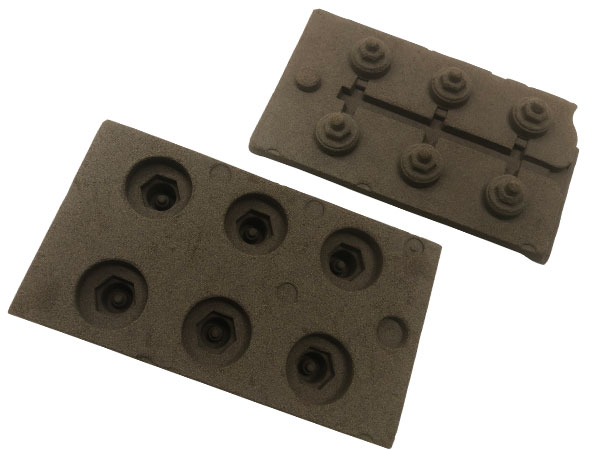

Achieved process reduction and structural freedom through phenolic resin molding,

contributing to the miniaturization and weight reduction of metal substitute parts.

Achieved process reduction and structural freedom through phenolic resin molding,

contributing to the miniaturization and weight reduction of metal substitute parts.

Friction material binder for brake disc pad and brake lining

We provide phenolic resins for friction material binder that have heat resistance, adhesiveness and flexibility etc.

Binder for wet type clutch friction material for automatic transmission

We provide liquid phenolic resins that have excellent coating and impregnation for production process of paper friction material.

Binder for dry type clutch friction material for manual transmission

We provide powder phenolic resins that are suitable for impregnation coating process of glass roving.

Reinforcement and tackifier for car tires rubber

We have various resins and tackifiers which have compatibility with various rubbers and modification.

Binder for engine casting, aluminum casting, main mold component, hollow core, solid core

We provide phenolic resins that have excellent strength and curability for shell mold binder.