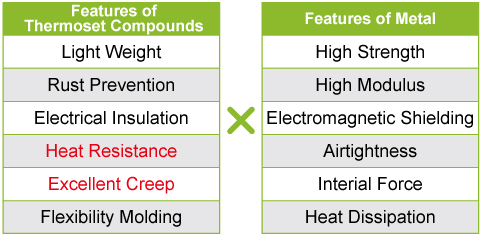

MobilityMiniaturization and Light Weight

Achieved process reduction and structural freedom through phenolic resin molding,

contributing to the miniaturization and weight reduction of metal substitute parts.

Achieved process reduction and structural freedom through phenolic resin molding,

contributing to the miniaturization and weight reduction of metal substitute parts.

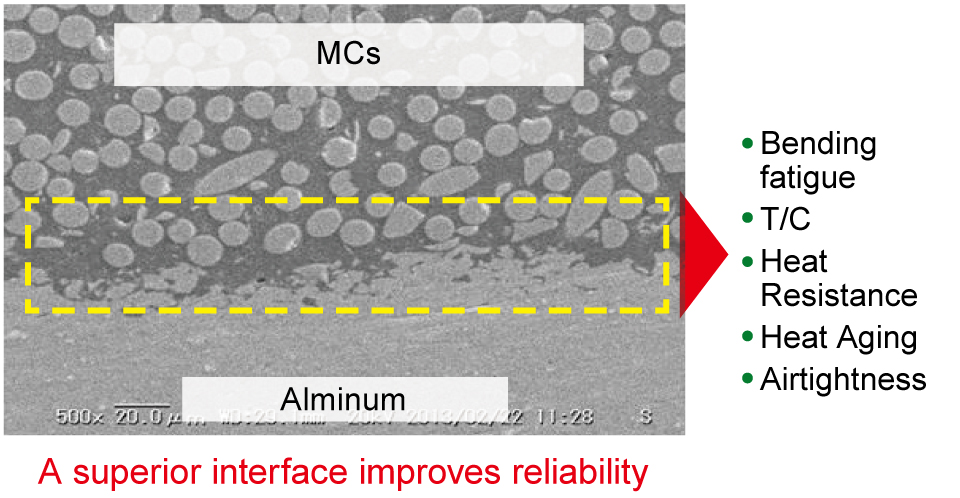

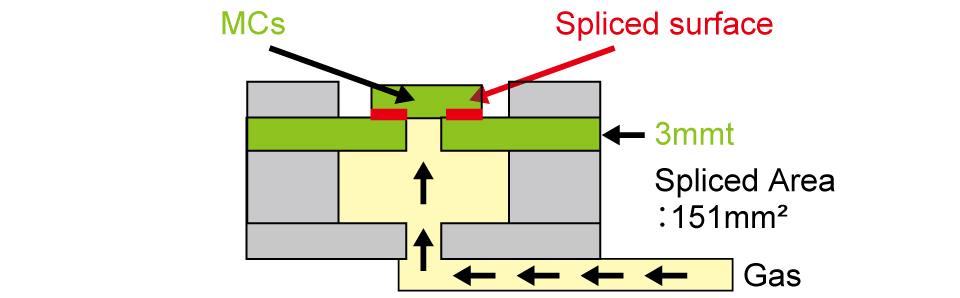

Provides excellent airtightness after the thermal cycle

Metal:Aluminum A5052(Etching:Laser/Chemical)

Method:JIS Z 2331

Condition:TC(-40℃↔︎150℃、Each 30min)~2000cyc

| Condition | Medium | Pressure | Result | |

|---|---|---|---|---|

| Laser | Chemical | |||

| Initial | Air | 1MPa | No Leakage | No Leakage |

| Oil | 7MPa | No Leakage | No Leakage | |

| After TC ~2000 cyc | Air | 1MPa | No Leakage | No Leakage |

| Oil | 7MPa | No Leakage | No Leakage | |

※Measuring limit : 1MPa/Air 7MPa/Oil

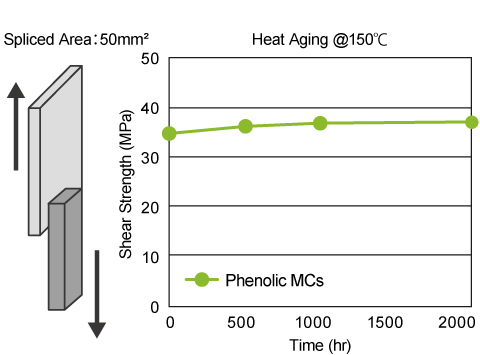

Povides excellent adhesion to metal after 150℃ heat aging test

Metal:Aluminum A5052(Laser)

Method:ISO Z 19095

Reliability Test:Heat Aging Test(150℃、〜2000h)