MobilityElectrification

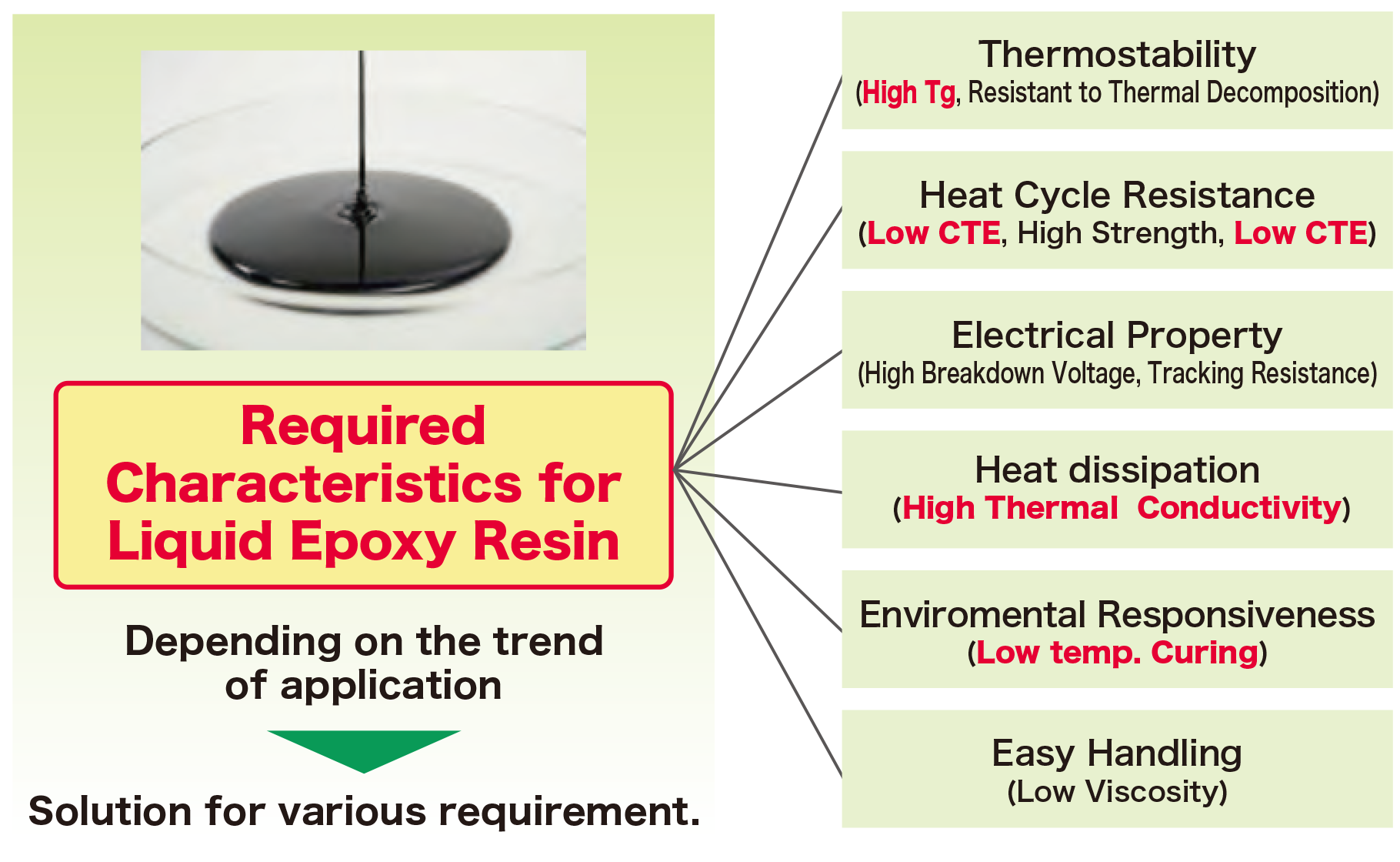

High heat resistance and high insulation thermosetting resin

improves

functionality and reliability of electric power train.

High heat resistance and high insulation thermosetting resin

improves

functionality and reliability of electric power train.

| Item | Condition/Unit | Current Products | Development Material | |||

|---|---|---|---|---|---|---|

| ECR-2222K /ECH-222G |

ECR-1004 /ECH-4 |

High Reliability Low α& Modulus |

High Thermal Conductivity |

Environment-Friendly Low Temp. Curing |

||

Liquid Resin Properties

| Mixing Ratio | Epoxy/Hardner | 100/100 | 100/100 | 100/100 | 100/100 | 100/5 |

| Mixture Viscosity | 60℃・Pa・s | 0.5 | 2 | 5 | 5 | 1 |

Properties of Cured Materials

| Curing Condition | 100℃/2h +140℃/2h |

130℃/2h +180℃/2h |

100℃/1.5h +200℃/2h |

130℃/1h +180℃/2h |

80℃/1h | |

| Flexural Strength | R.T.・MPa | 130 | 130 | 125 | 130 | 100 |

| Flexural Modulus | R.T.・GPa | 9 | 17 | 11 | 29 | 15 |

| Tg | TMA・℃ | 125 | 210 | 205 | 195 | 100 |

| α<Tg | TMA・ppm | 40 | 16 | 11 | 14 | 25 |

| Thermal Conductivity | LFA・W/(m・K) | 0.7 | 0.6 | 0.6 | 3.0 | 1.0 |

| : Above characteristic values are representative values, not guaranteed. The characteristics of the developed product are subject to change. |

Please fill out and submit the following format to make an inquiry.