MobilityElectrification

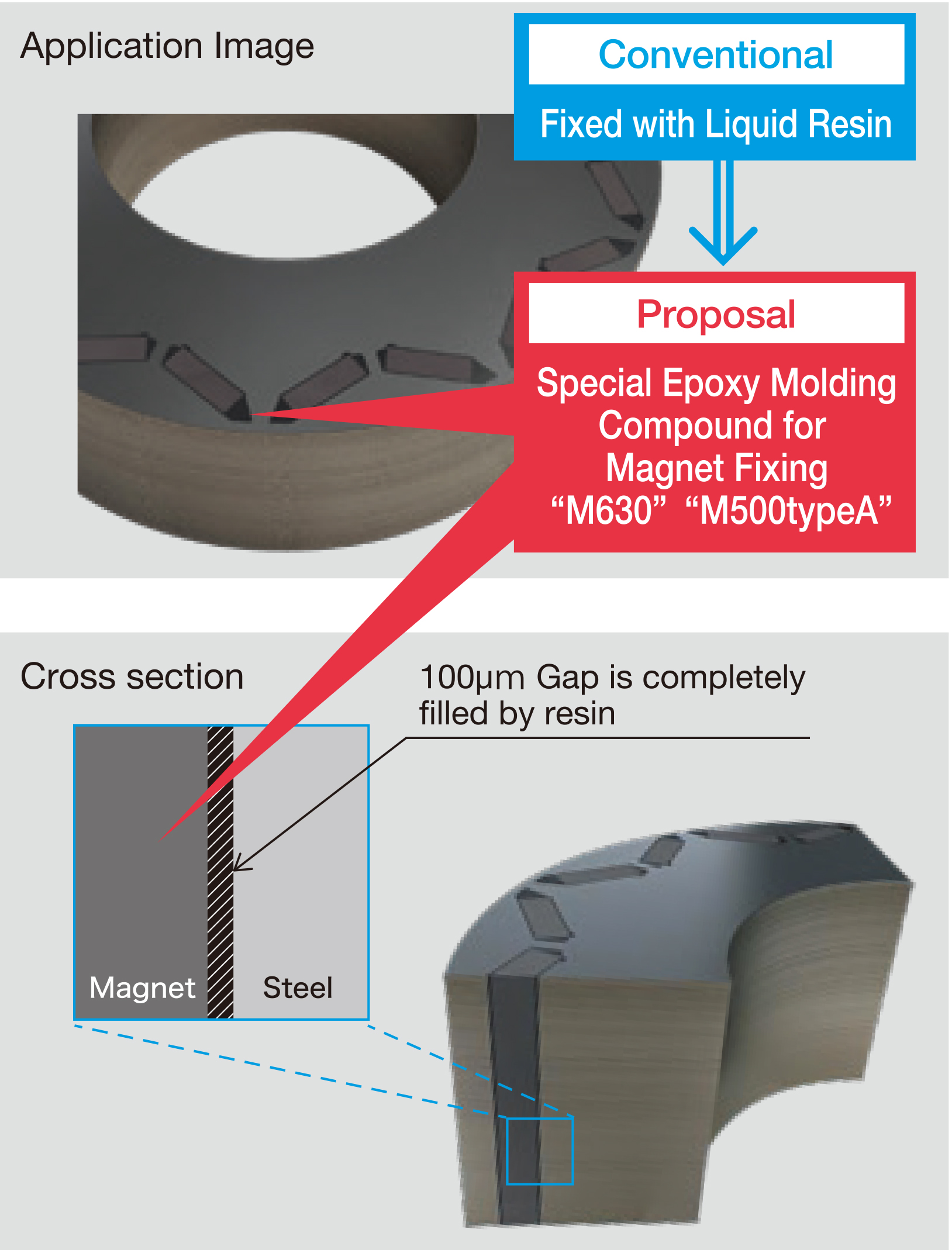

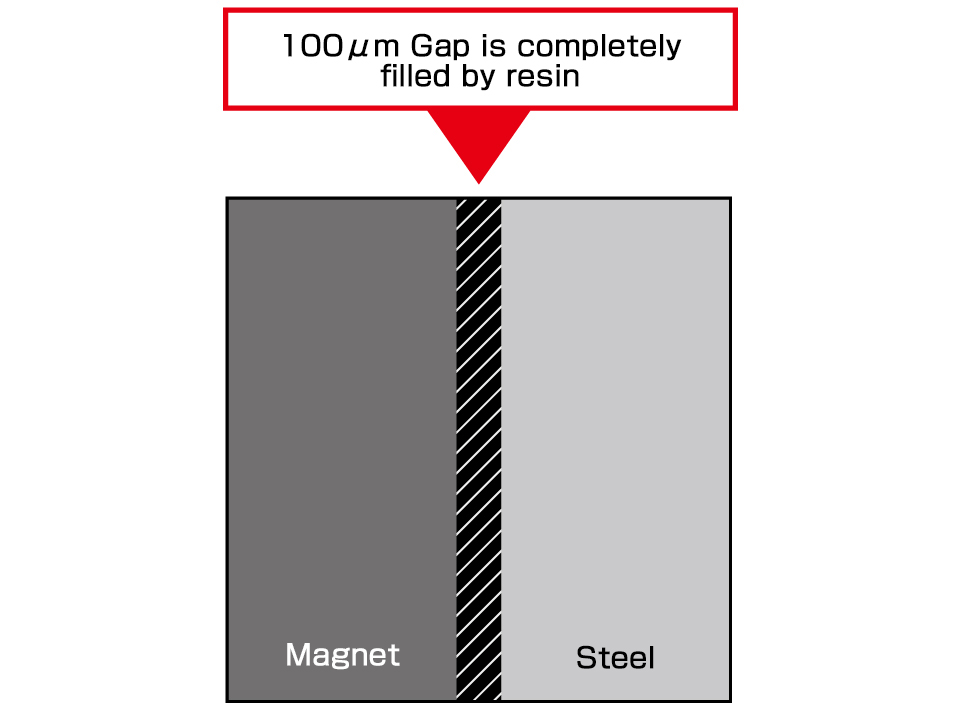

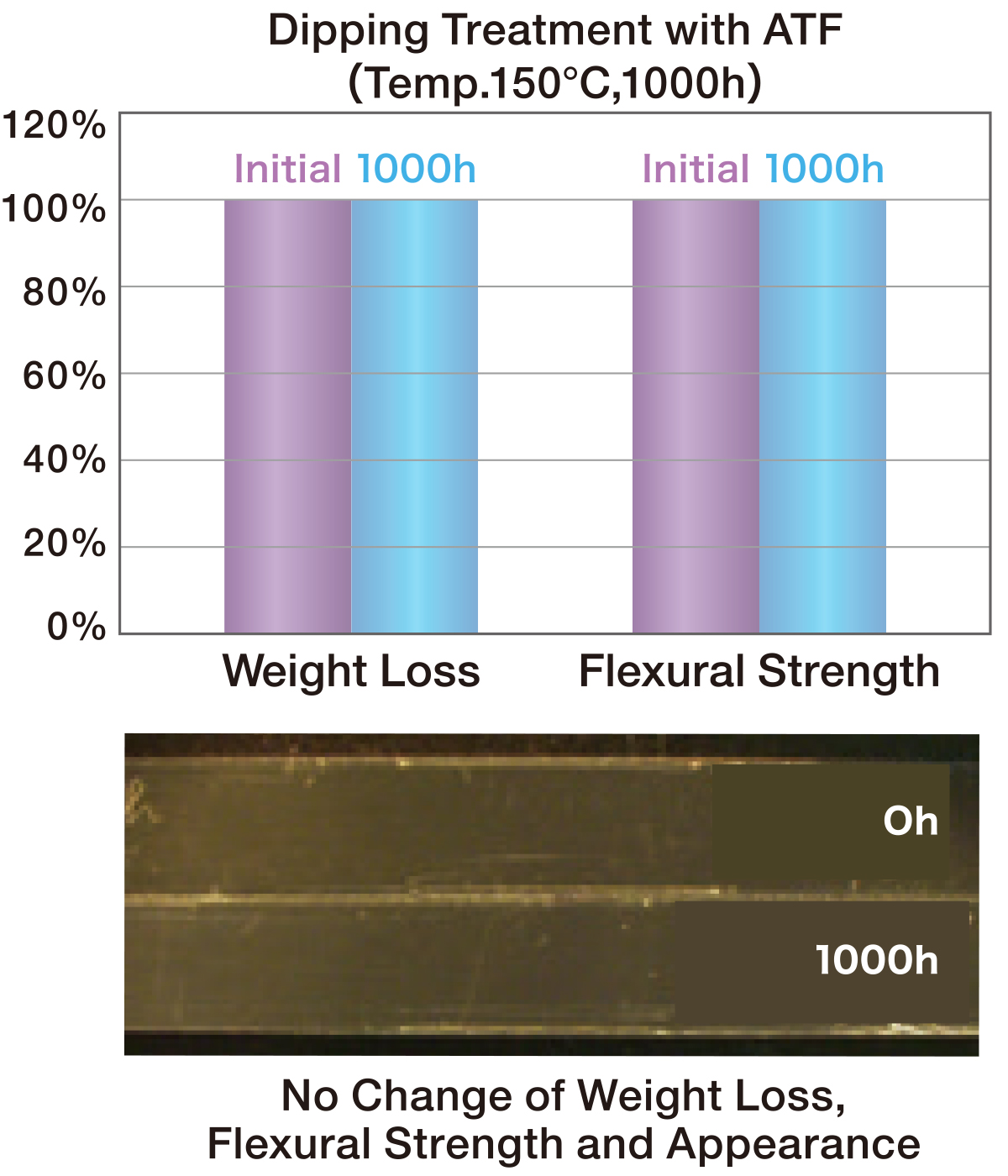

High heat resistance and high insulation thermosetting resin

improves

functionality and reliability of electric power train.

High heat resistance and high insulation thermosetting resin

improves

functionality and reliability of electric power train.

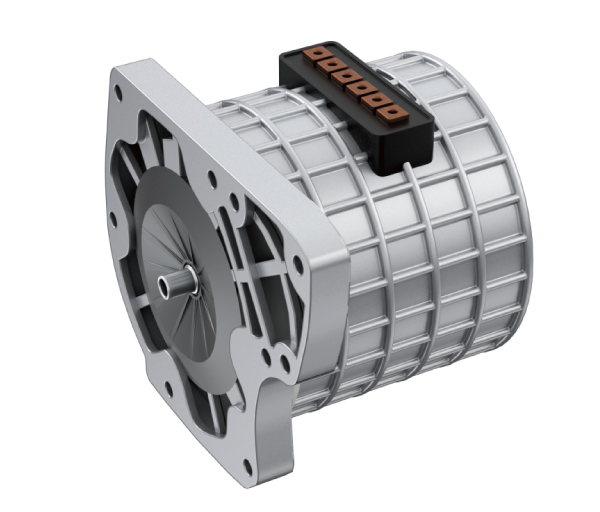

Main Motor of EV

Please fill out and submit the following format to make an inquiry.