MobilityElectrification

High heat resistance and high insulation thermosetting resin

improves

functionality and reliability of electric power train.

High heat resistance and high insulation thermosetting resin

improves

functionality and reliability of electric power train.

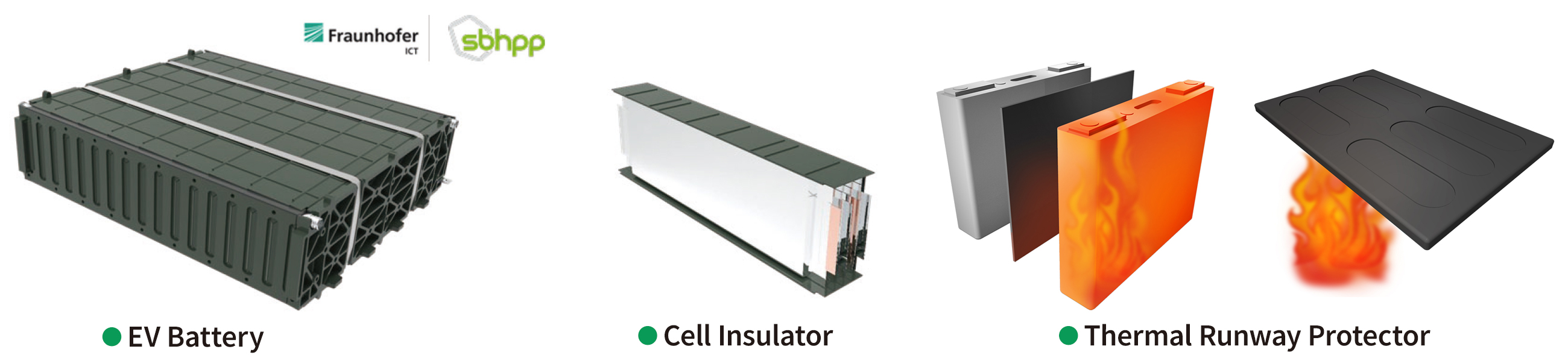

| Item | Phenolic Compound for EV Battery | ||

| Conventional Fire Resistance | PM-5820 (Development) High Fire Resistance |

||

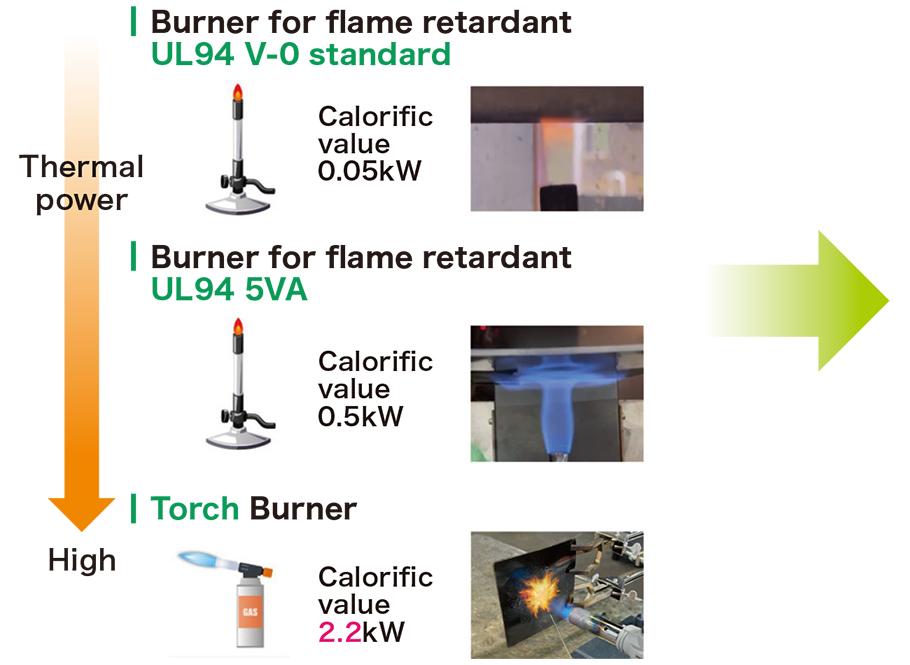

| Fire Resistance (Flame Exposure) |

to UL94 Standard Burner |

++ | ++ |

|---|---|---|---|

| to UL94 5V Burner | ++ | ++ | |

| to Torch Burner | + | ++ | |

| Specific Gravity | - | 1.78 | 1.91 |

| Flexural Strength | MPa | 210 | 190 |

| Flexural Modulus | GPa | 16 | 21 |

| Dielectric Strength | MV/m | 9 | 10 |

*Above value is typical, not guarantee.

**Fire resistance performance ‒ tested by Sumitomo Bakelite Co., Ltd. method

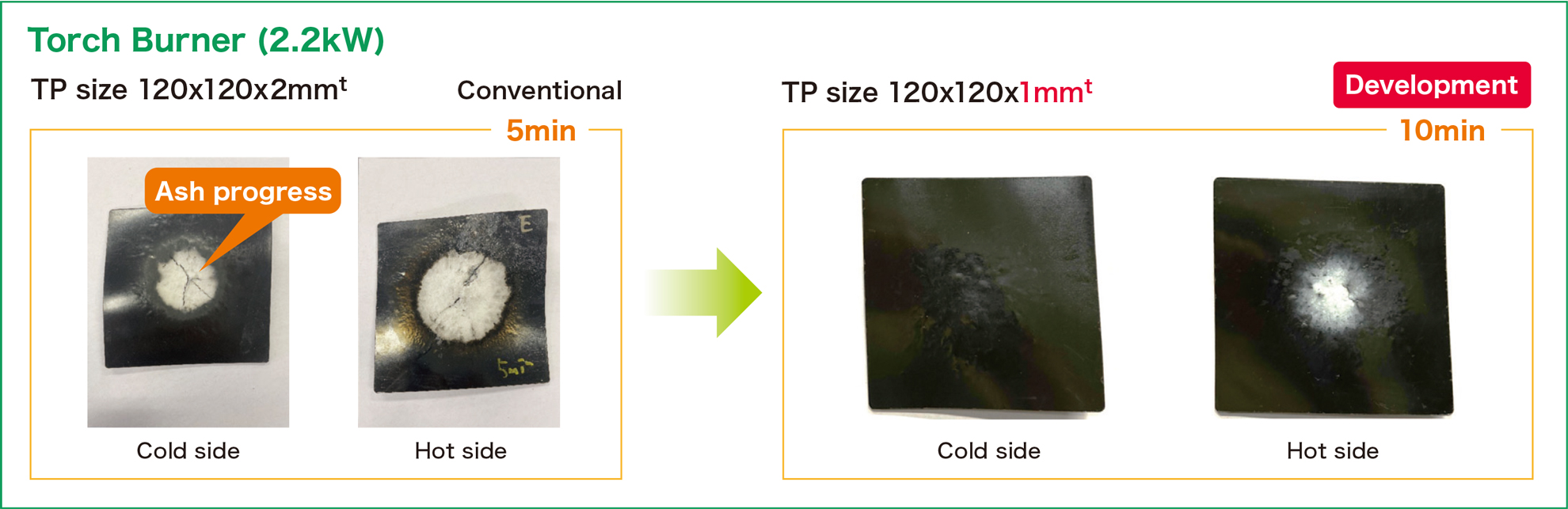

Test method - One side of 120mm x 120mm x 2mmthickness test specimen was exposed to continuous

flame from each burner for 5 minutes.

Burner distance is 70mm between TP

Judgment Criteria

++ No flame penetration and suppression of charring on the back side (cold side)

+ No flame penetration, but charring on the back side (cold side) was progressing

Please fill out and submit the following format to make an inquiry.