Business Overview by Segment High-performance Plastics

HIGH PERFORMANCE PLASTICS

Transforming our product portfolio and creating products with high social value

A Review of Fiscal Y2024

In FY2024, we saw strong demand for molding compounds and molded products for electrical and automotive

applications in China and the rest of Asia. In Europe, we recorded good sales of phenolic resins for brake

pads. However, the business environment worsened in North America for phenolic resins, and our North American

subsidiary recorded impairment losses. Sales of aircraft components were affected by customer strikes, but

demand recovered in the fourth quarter.

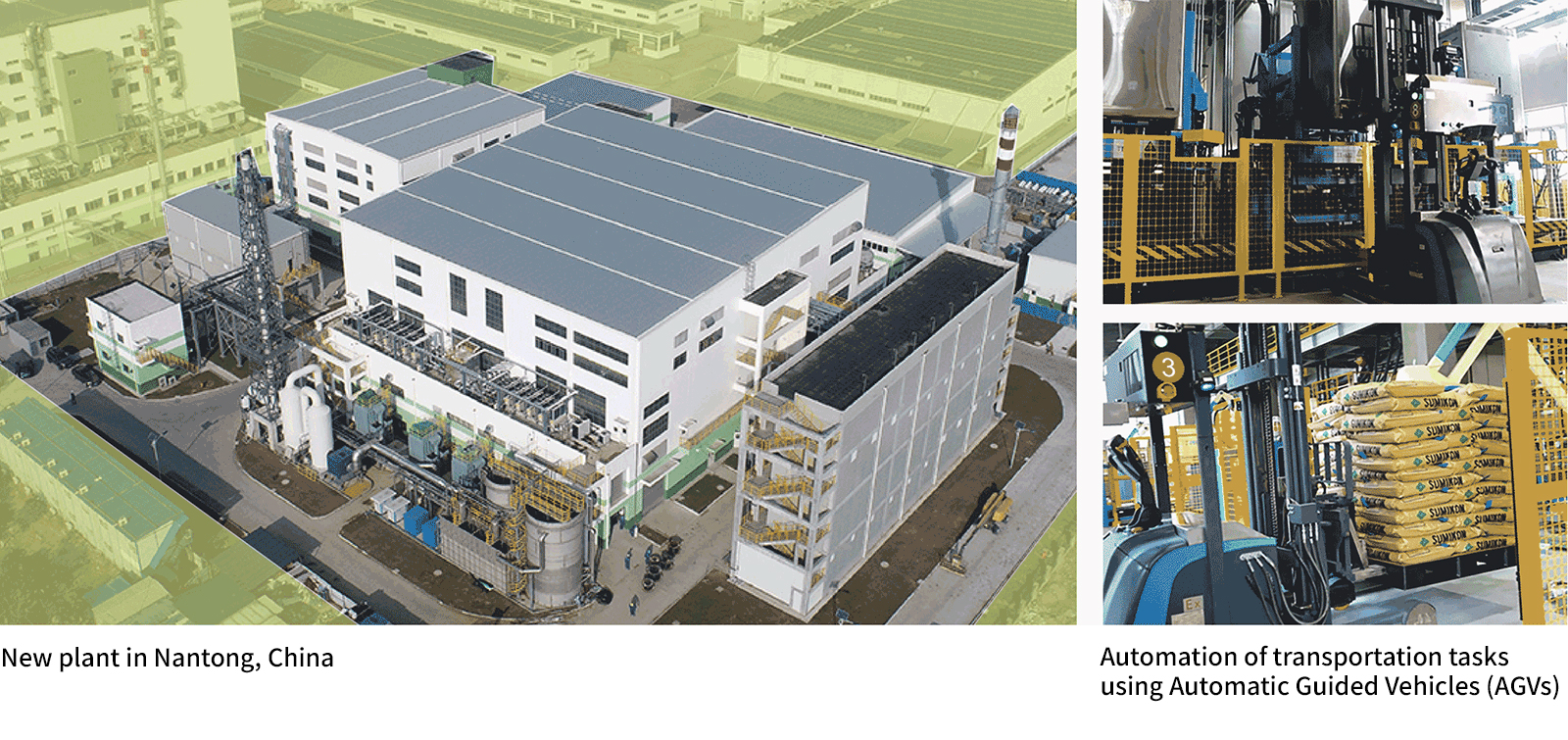

Amid this business environment, we opened a new plant with state-of-the-art facilities in China and rolled out

measures to increase productivity around the globe, including restructuring the phenol-related business in

North America and optimizing production sites in Japan. We also attempted to improve profitability in North

America through price optimization of unprofitable products.

We have identified electric vehicles, semiconductors, aircraft, and environmental response as enhanced areas

in transforming our product portfolio toward high value-added products. We developed and sold products

leveraging our technical expertise in each of these areas. We are starting to see results for products with

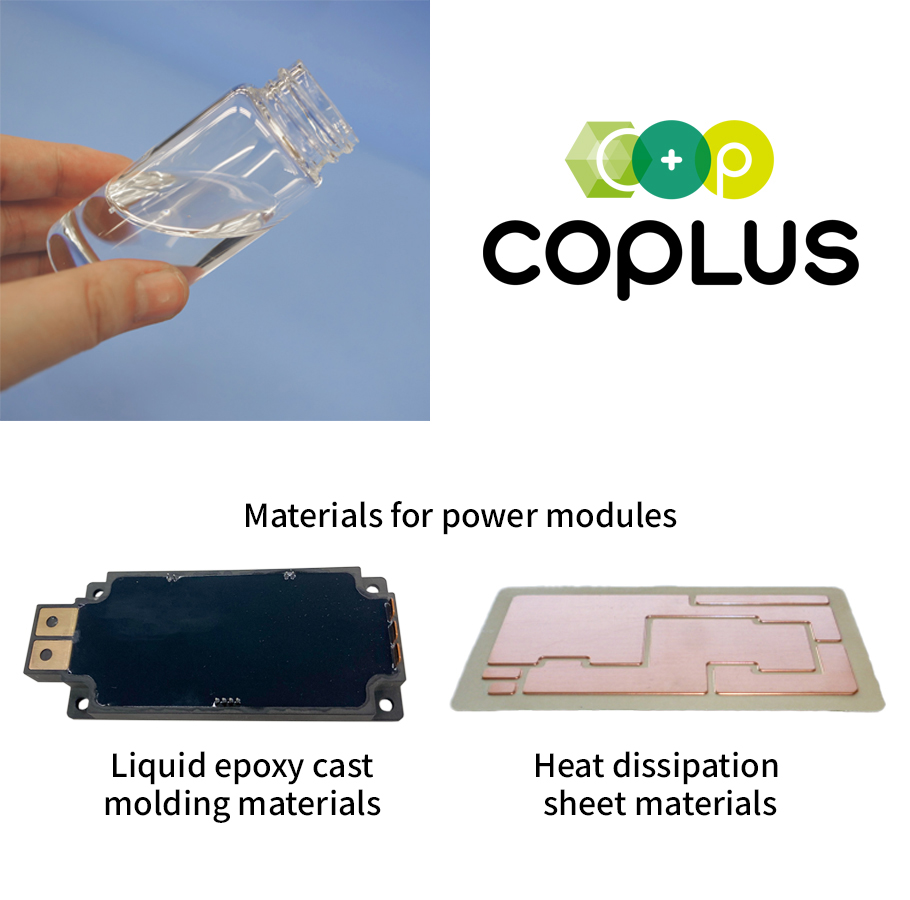

future potential for sales expansion, such as COPLUS™ cyclo-olefin polymer which has been adopted for AI

semiconductors, as well as heat dissipation sheet materials for power modules.

Initiatives in FY2025

In FY2025, we will proceed with structural reform of the phenolic resin business in North America. We will also introduce automation processes from our Nantong Plant in China to plants in other regions, improving productivity to increase profitability. In our enhanced areas, in addition to COPLUS™ and heat dissipation sheet materials, we aim to expand sales of aircraft components in Europe. We will also improve profitability in this segment by increasing the sales ratio of high value-added products including environmentally-friendly ultra low monomer water-soluble phenolic resin and high-voltage, high-heat resistant molding compounds which we aim to apply to electric vehicle batteries.

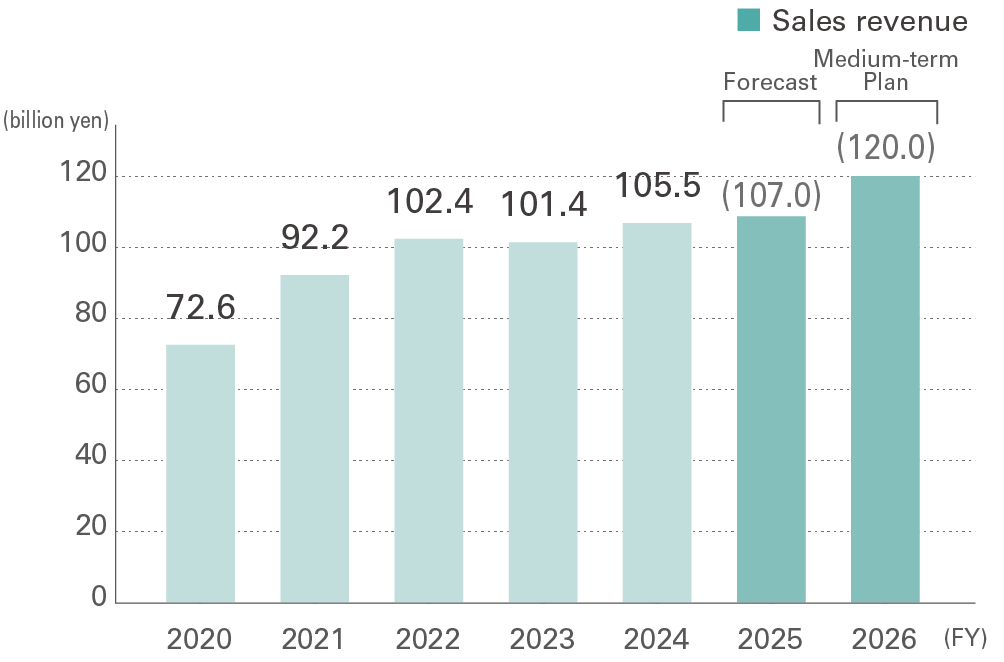

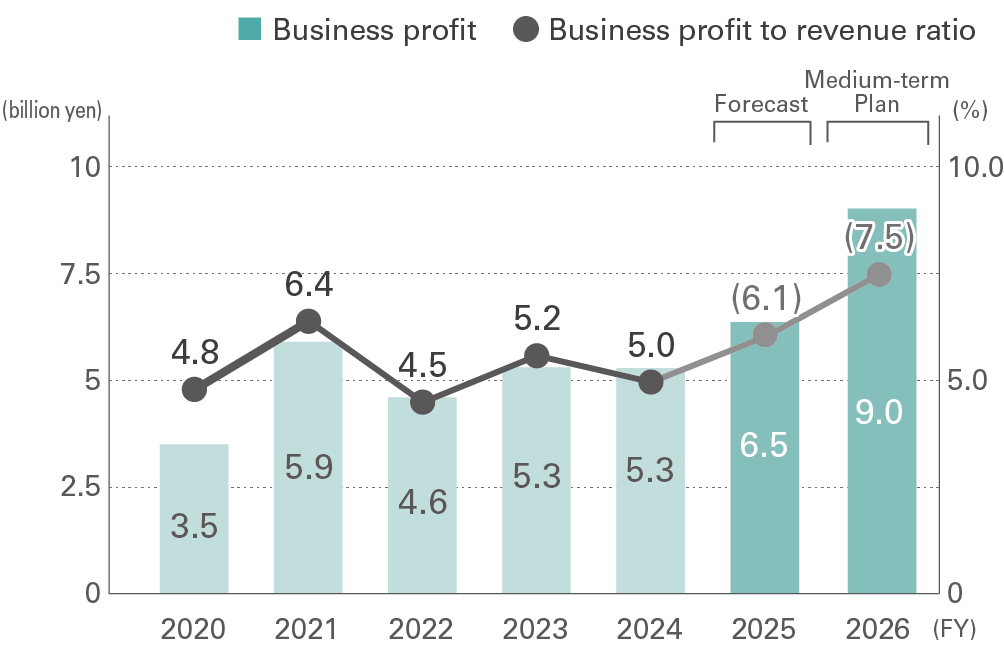

Business Performance (actual results, forecast, Medium-term Business Plan)

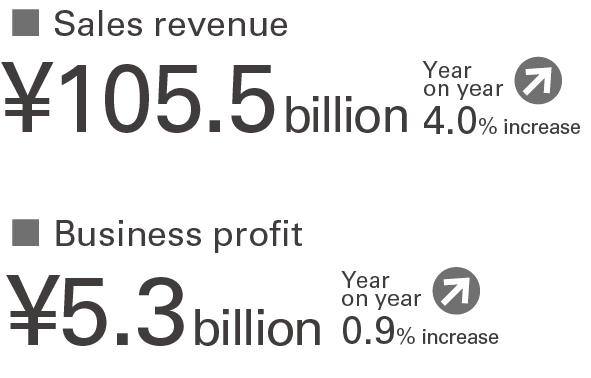

FY2024 Business Performance for the Segment

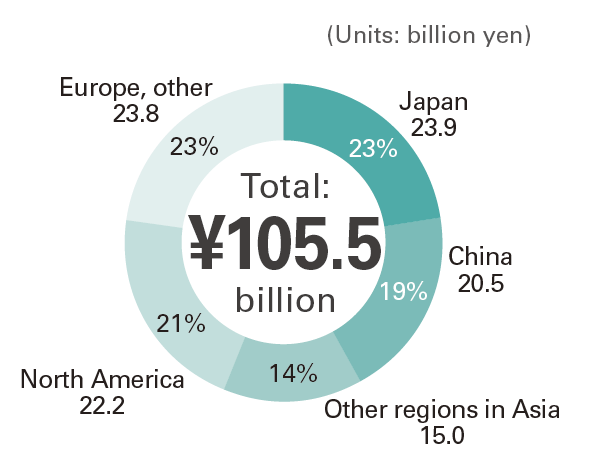

Sales Revenue by Region

Priority SDGs

Business Characteristics/Strengths

- Technical expertise in creating unique materials, built up as a pioneer in thermosetting resins

- A seamless value chain for resins, molding compounds, and molded products

- A global business framework responding to key markets

- Environmentally-friendly technologies and products such as lignin-modified phenolic resins and biomass-based polymers

- Strong connections with supply chains in key industries such as automotive, electronics, and aircraft, and relationships of trust with customers

- Ability to propose solutions in a cross-business manner through One Sumibe Activities

Opportunities and Risks

Opportunities

- Increasing need for heat management due to higher performance of power semiconductors

- Growing market for AI semiconductors and other advanced semiconductors

- Increased demand for environmentally friendly products due to tougher environmental regulations

- Acceleration of in-house production in China

- Further growth in demand for aircraft

Risks

- Economic downturn due to changes in tariff policies by the US and other countries

- Stagnation of the xEV market

- Slower growth due to intensified competition for mainstay products and the maturity of their markets

- Increased manufacturing costs due to the introduction of carbon pricing

FY2025 Business Strategy and Enhanced Areas

01. Structural reforms to strengthen profitability

- (1) Transform phenol-related business in North America to focus on profit

- (2) Promote portfolio transformation toward high value-added products

- (3) Optimize production sites and improve productivity

02. Initiatives for products in enhanced areas

Portfolio transformation toward high value-added products

[Development

and sales of products in enhanced areas]

Electric vehicles

Batteries, e-Axle, electrical components

Develop high-voltage, high-heat resistant materials to meet requirements as electric vehicles evolve. Started

delivering samples

Semiconductors

COPLUS™ (cyclo-olefin polymer) adopted for AI semiconductors

Business expansion of liquid epoxy cast molding materials for power modules

Heat dissipation sheet materials starting to be used in vehicle power modules. Under evaluation for next generation

Aircraft

Started mass production of cargo liners for Europe. Actively propose biomass materials

Environmentally-friendly materials

Ultra low monomer water-soluble phenolic resin adopted in semiconductor-related applications

Start proposing environmentally-friendly new materials for brakes to comply with the Euro 7 emissions standard