June 17, 2020

Tokyo, Japan –June 17, 2020 Sumitomo Bakelite Co., Ltd. (TOKYO:4203 HQ: Shinagawa-ku, Tokyo, President and Representative Director: Kazuhiko Fujiwara) aims to promote further application of Thermoset Compounds in powertrain systems, which are the central components to electric vehicles, ecofriendly vehicles, etc. To achieve this, the company established the Next e-Axle Market Promotion Project Team on January 1st, 2020 with the purpose to design, manufacture, and generate data verifying the benefits of utilizing Thermoset Compounds. These benefits enable smaller, more lightweight/low-vibration, more low-noise and better heat dissipation designs. Sumitomo Bakelite Co., Ltd. is supporting the rapidly growing market for electric vehicles as the opportunity to expand the Thermoset Compounds industry. While applying our molding compound technology developed through semiconductor encapsulation compound applications (EME) and phenolic molding compound (PM), we are moving our efforts forward to appeal to major automotive-related companies both in Japan and overseas.

Sumitomo Bakelite Co., Ltd. has a long history of producing and selling molding compounds and Thermoset Compounds, including phenolic and other kinds of thermoset, as materials for automotive applications. In recent years, with high growth expected in the electric vehicle market, the company has already begun joint development of materials for fixing motor magnets, etc. with a number of clients and continues to advance these efforts. On the other hand, due to structural changes in the automotive-related industry in recent years, there has been a demand from clients for technology and information that is more advanced than ever before.

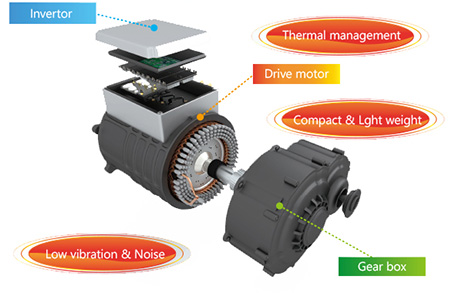

In particular, there has been an increase in demand for electric powertrains (electric axles) integrated with motors, inverters, and gearboxes. With these demands, we face the essential challenges of producing smaller/more lightweight and with lower vibration/more low-noise, as well as how to deal with the heat released at high output.

|

Now, in order to respond to client demand, the company has decided to take the Compound design and formulation technology that we have refined up until this point and apply it to electric axle design, manufacturing, and data acquisition. A 150 kilowatt output motor is scheduled to be completed in 2021. Upon its completion, we will run the motor to acquire data and present detailed information on how to improve its performance in areas such heat dissipation. Our plan is to work to make it possible to also share with our clients technology that can contribute to their product development. It is in this manner that Sumitomo Bakelite Co., Ltd. hopes to make way for even greater expansion in industries that work with our electric axles. We have also established both a new Mobility Materials Sales Dept. and a global production system, and aim to achieve sales of 12 billion yen in electric axle-related business in the 2025 fiscal year. |

Electric Axle Solutions |

Main related products

- Inverter applications: molding compounds for inverter covers, encapsulation compound materials for power modules, heat dissipation sheets, materials for sintering paste

- Motor applications: materials for fixing rotor magnets, stator materials, direct cooling systems

- Motor gear applications: molding compounds for motor gear housing (PM) has spurred the creation of new demand, and Sumitomo Bakelite Co., Ltd. now also focuses on the following products for automotive use as new applications for these products.

For inquiries on this product

Next e-Axle Market Promotion Project Team, Sumitomo Bakelite Co., Ltd.

Tel: +81-3-5462-8929 E-mail: exh-SCM@ml.sumibe.co.jp