Difference in Warpage between Resin Substrates and Ceramic Substrates during the Processing stage

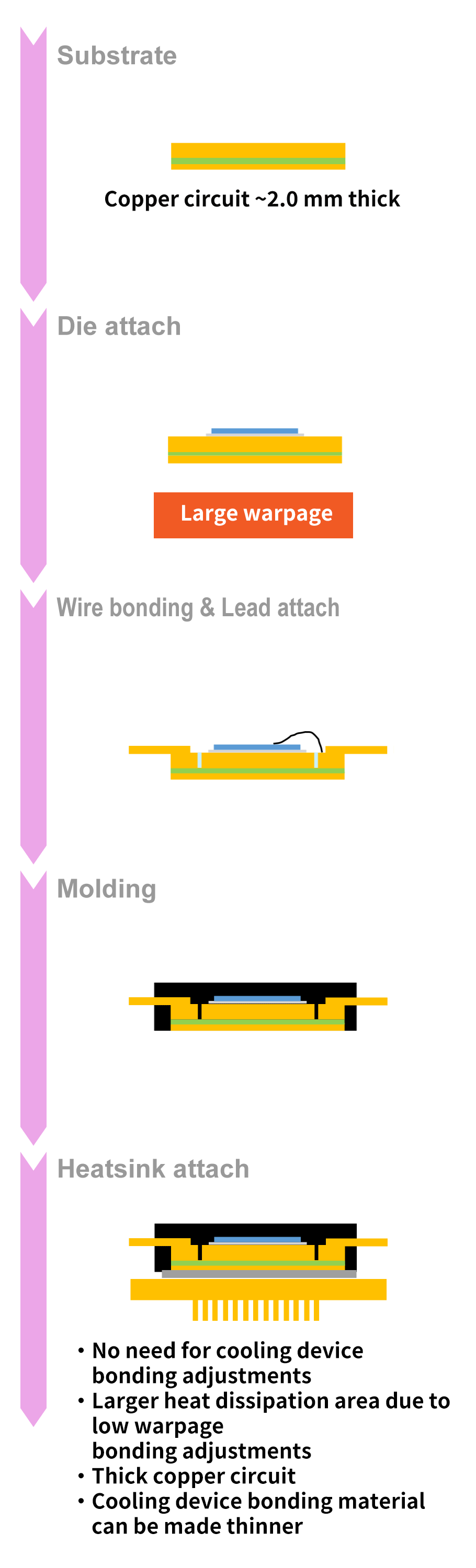

Resin Substrate

Process advantages:

Low warpage, no insulation layer cracks, easy cooling device bonding, reduced stress, high reliability

Low warpage, no insulation layer cracks, easy cooling device bonding, reduced stress, high reliability

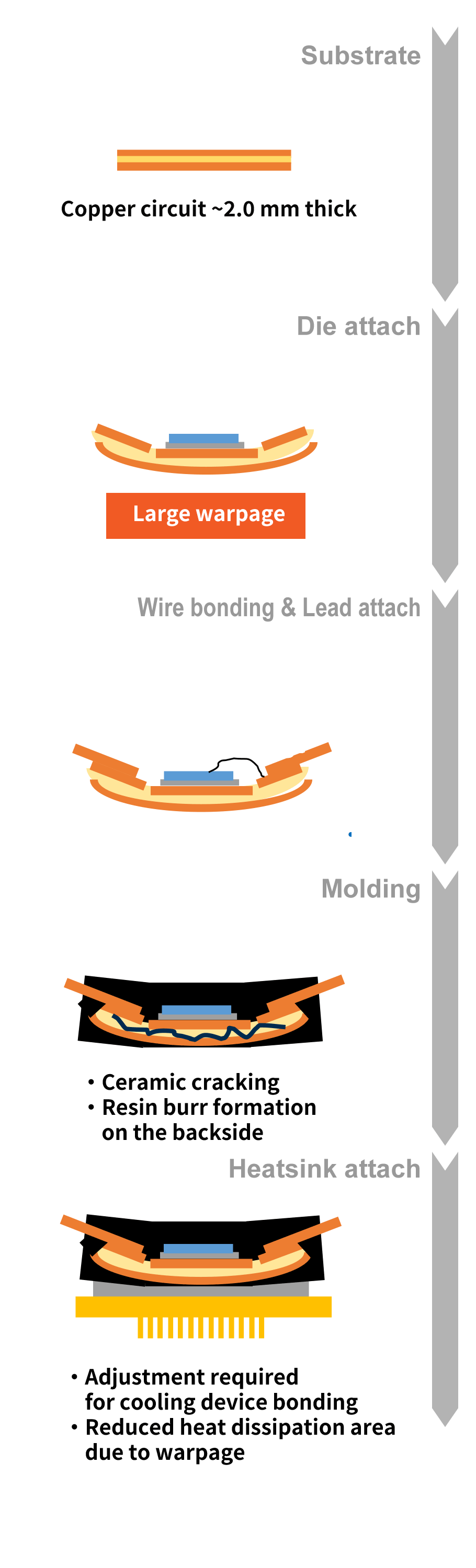

Ceramic Substrate

Process disadvantages:

The ceramic substrate exhibits significant warpage behavior due to the CTE mismatch between ceramic and copper, causing various problems.

The ceramic substrate exhibits significant warpage behavior due to the CTE mismatch between ceramic and copper, causing various problems.

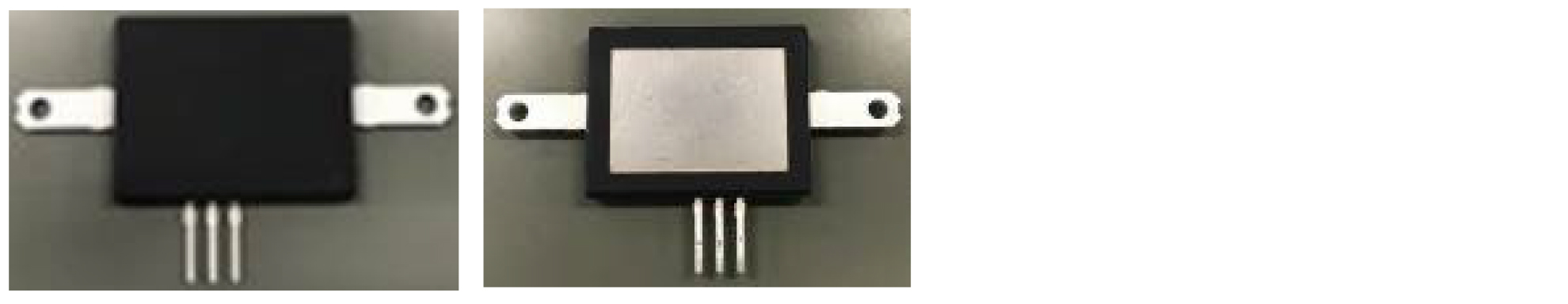

Heat Dissipation Sheets & Resin Substrates Achieve Process Advantages & High Reliability.

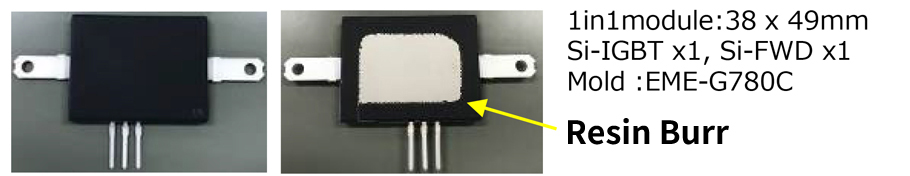

Differences in Warpage Between Resin Substrates and Ceramic Substrates in Power Modules

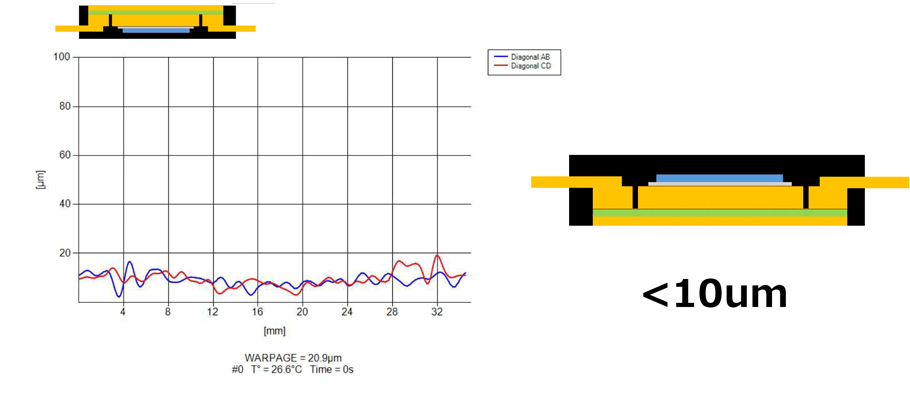

Resin Substrate Type

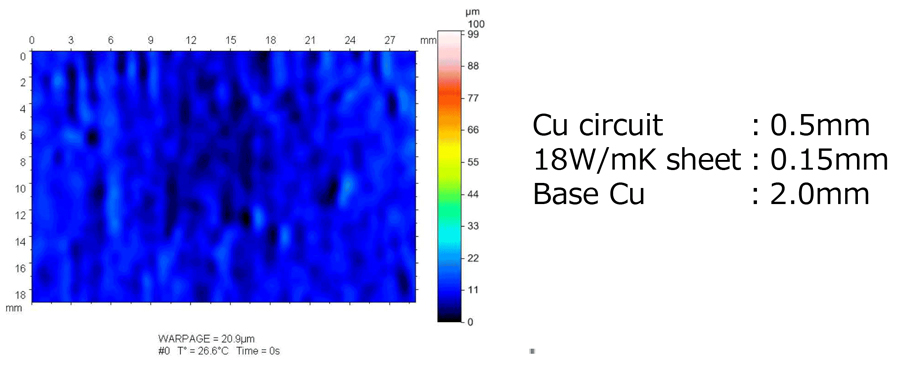

〇Results of Non-contact Warpage Measurement

⇒ Deformation is Extremely

Minimal

3D Data

Diagonal Data

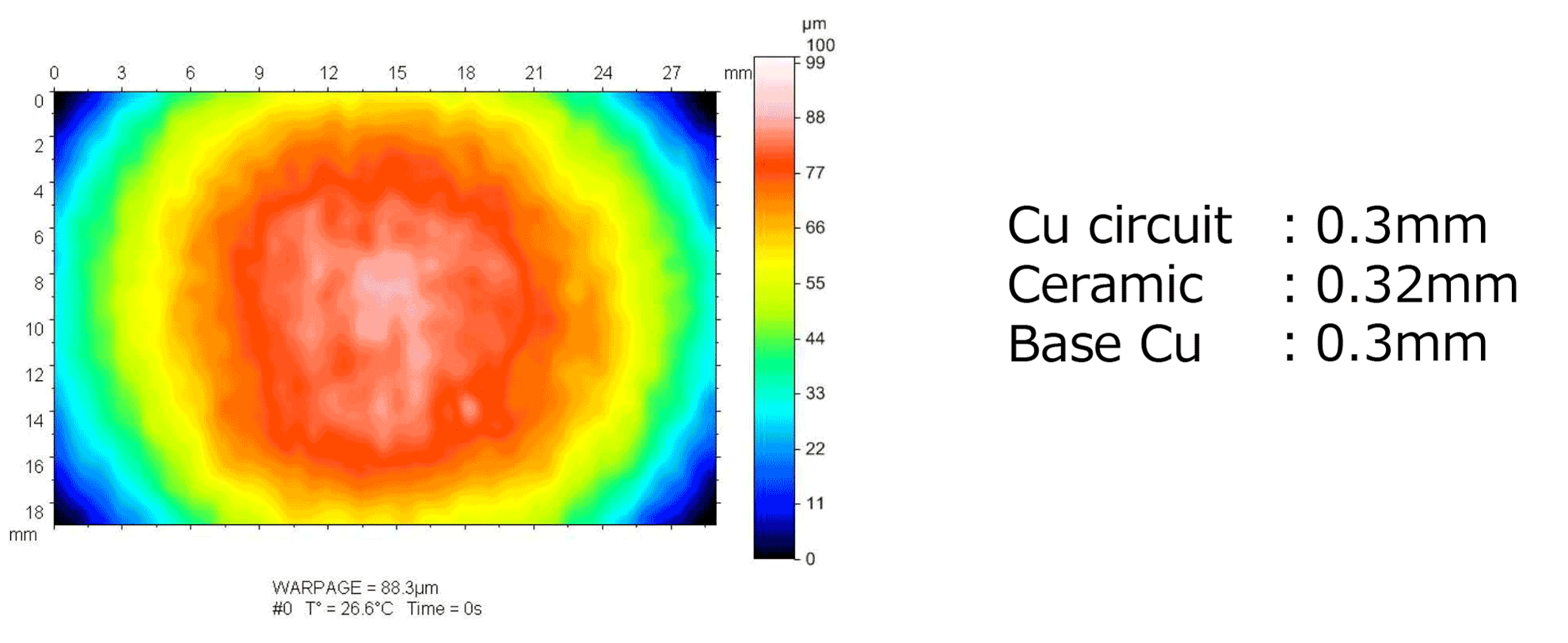

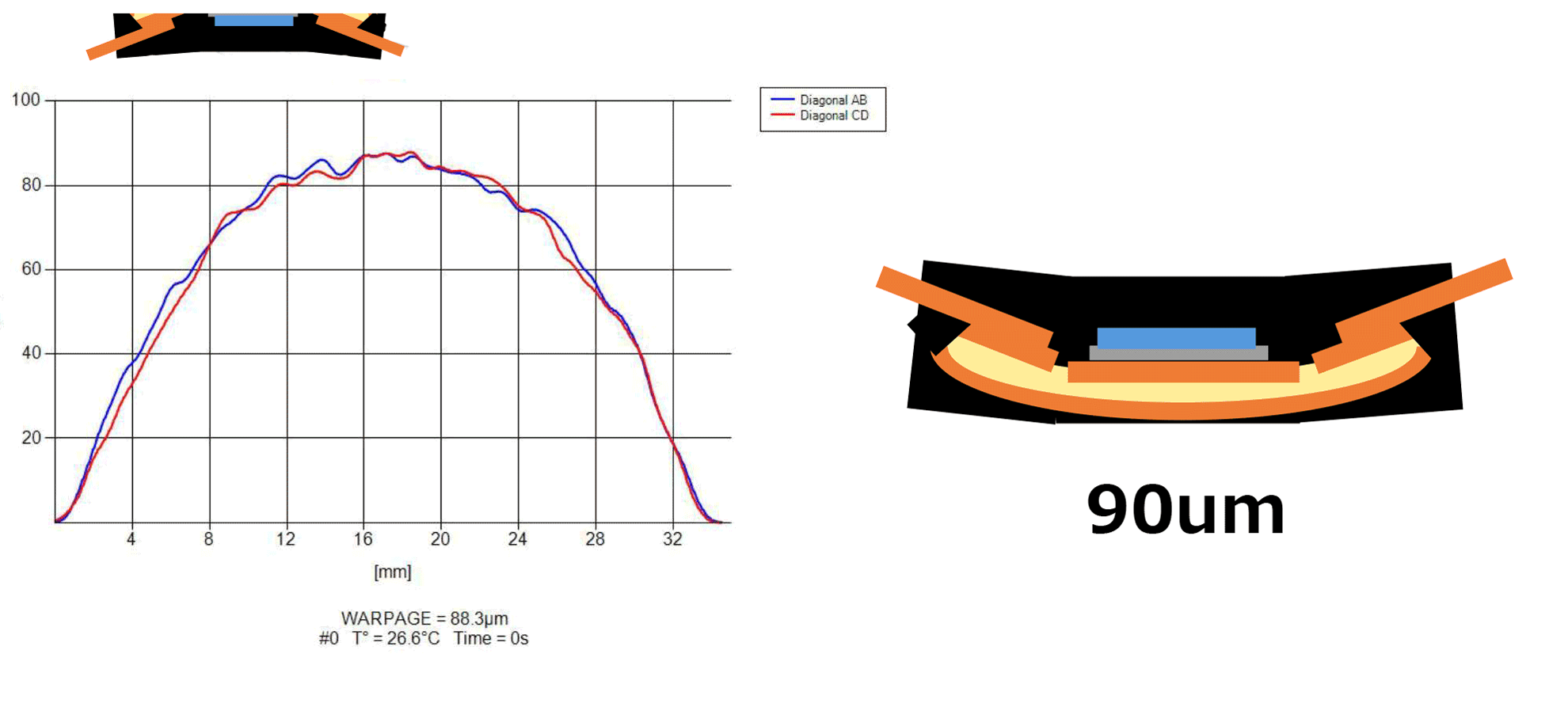

Ceramic Substrate Type

〇 Results of Non-contact Warpage Measurement

⇒ Deformation Occurs

with the Heatsink Side Being Convex

3D Data

Diagonal Data

The Warpage Amount of the Resin Substrate in a Package is

Reduced by 80 μm Compared to the Ceramic Substrate.

Reduced by 80 μm Compared to the Ceramic Substrate.

Email us about our Division/Department.

Inquiry

Inquiry